NZQA unit standard 8963 version 5

advertisement

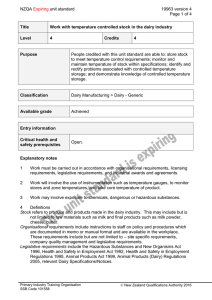

NZQA Expiring unit standard 8963 version 5 Page 1 of 3 Title Apply the principles of rationalised testing in the New Zealand dairy industry Level 4 Credits 6 Purpose People credited with this unit standard are able to: explain the procedure for determining the quality control points for a rationalised testing programme; explain the procedure for developing and implementing a product certification system; and report on the analysis of moisture results of a dairy product in the individual's workplace in the New Zealand dairy industry. Classification Dairy Manufacturing > Dairy Laboratory Methodology Available grade Achieved Entry information Critical health and safety prerequisites Open. Explanatory notes Organisational requirements refer to instructions to staff on policy and procedures which are documented in memo and/or manual format and are available in the workplace. These requirements include but are not limited to – site specific requirements, company quality management requirements, hygiene, health and safety, regulatory and legislative requirements. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 8963 version 5 Page 2 of 3 Outcomes and evidence requirements Outcome 1 Explain the procedure for determining the quality control points for a rationalised testing programme. Evidence requirements 1.1 The techniques used for collecting process capability data are explained in accordance with organisational requirements. Range 1.2 The techniques for characterising the process are explained in accordance with organisational requirements. Range 1.3 flow diagrams, brainstorming techniques, cause and effect, Hazard Analysis Critical Control Programme (HACCP), statistical process control, historical process data, historical test results. normal variability, acceptable variability, measurement accuracy, significance of causes, process improvements. The procedure for identifying effective control points are explained in accordance with organisational requirements. Range control frequencies, control point reliability, action limits, action responses, responsibilities, authority. Outcome 2 Explain the procedure for developing and implementing a product certification system. Evidence requirements 2.1 The product certification criteria are explained in accordance with organisational requirements. Range quality control schedules, documentation and record requirements, additional product testing. 2.2 The implementation and review procedures are explained in accordance with organisational requirements. 2.3 The integration of the rationalised testing programme into site quality systems is explained in accordance with organisational requirements. Range operating procedures, documentation, training, communications, auditing, review. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 8963 version 5 Page 3 of 3 Outcome 3 Report on the analysis of moisture results of a dairy product in the individual’s workplace. Evidence requirements 3.1 The major causes that effect process variability are identified using a cause and effect diagram. 3.2 The historical process control and product grading data are analysed to determine the process variability for one production run. 3.3 The suitability of rationalisation is assessed in relation to process capability in accordance with organisational requirements. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 28 April 1997 31 December 2017 Revision 2 2 July 1999 31 December 2017 Revision 3 13 June 2003 31 December 2017 Rollover 4 26 January 2007 31 December 2017 Review 5 15 October 2015 31 December 2017 Consent and Moderation Requirements (CMR) reference 0022 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016