Chapter 4

advertisement

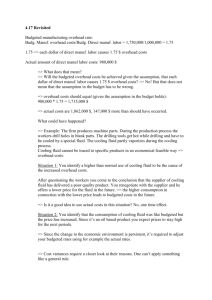

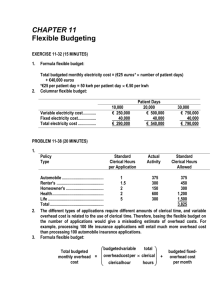

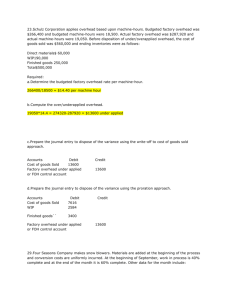

Chapter 4 4-17 1. (20 min.) Actual costing, normal costing, accounting for manufacturing overhead. Budgete d manufactur ing overhead rate Actual manufactur ing overhead rate = Budgeted manufactur ing overhead costs Budgeted direct manufactur ing labor costs = $1,750,000 = 1.75 or 175% $1,000,000 = Actual manufactur ing overhead costs Actual direct manufactur ing labor costs $1,862,000 = 1.9 or 190% $980,000 Costs of Job 626 under actual and normal costing follow: = 2. Direct materials Direct manufacturing labor costs Manufacturing overhead costs $30,000 1.90; $30,000 1.75 Total manufacturing costs of Job 626 Actual Costing Normal Costing $ 40,000 30,000 $ 40,000 30,000 57,000 $127,000 52,500 $122,500 3. Total manufacturing overhead allocated under normal costing = Actual manufacturing Budgeted labor costs overhead rate = $980,000 1.75 = $1,715,000 Underallocated manufacturing = overhead Actual manufacturing – Manufacturing overhead costs overhead allocated = $1,862,000 $1,715,000 = $147,000 There is no under- or overallocated overhead under actual costing because overhead is allocated under actual costing by multiplying actual manufacturing labor costs and the actual manufacturing overhead rate. This, of course equals the actual manufacturing overhead costs. All actual overhead costs are allocated to products. Hence, there is no under- or overallocatead overhead. 4-20 (20-30 min.) Job costing, accounting for manufacturing overhead, budgeted rates. 1. An overview of the product costing system is INDIRECT COST POOL COST ALLOCATION BASE Machining Department Manufacturing Overhead Machine-Hours Direct Manuf. Labor Cost Indirect Costs COST OBJECT: PRODUCT DIRECT COST Assembly Department Manufacturing Overhead Direct Costs Direct Materials Direct Manufacturing Labor Budgeted manufacturing overhead divided by allocation base: Machining overhead Assembly overhead: $1,800,000 = $36 per machine-hour 50,000 $3,600,000 = 180% of direct manuf. labor costs $2,000,000 2. Machining department, 2,000 hours $36 Assembly department, 180% $15,000 Total manufacturing overhead allocated to Job 494 3. Actual manufacturing overhead Manufacturing overhead allocated, 55,000 $36 180% $2,200,000 Underallocated (Overallocated) $72,000 27,000 $99,000 Machining $2,100,000 Assembly $ 3,700,000 1,980,000 — $ 120,000 — 3,960,000 $ (260,000) 4-21 (2025 min.) Job costing, consulting firm. 1. Budgeted indirect-cost rate = $13,000,000 ÷ $5,000,000 = 260% of professional labor costs INDIRECT COST POOL Consulting Consulting Support Support COST ALLOCATION BASE Professional Professional Labor LaborCosts Costs COST OBJECT: JOB FOR CONSULTING CLIENT DIRECT COSTS 2. Indirect Costs Direct Costs Professional Labor At the budgeted revenues of $20,000,000, Taylor’s operating income of $2,000,000 equals 10% of revenues. Markup rate = $20,000,000 ÷ $5,000,000 = 400% of direct professional labor costs 3. Budgeted costs Direct costs: Director, $200 3 $ 600 Partner, $100 16 1,600 Associate, $50 40 2,000 Assistant, $30 160 4,800 Indirect costs: Consulting support, 260% $9,000 Total costs $ 9,000 23,400 $32,400 As calculated in requirement 2, the bid price to earn a 10% income-to-revenue margin is 400% of direct professional costs. Therefore, Taylor should bid 4 $9,000 = $36,000 for the Red Rooster job. Bid price to earn target operating income-to-revenue margin of 10% can also be calculated as follows: or, Let R = revenue to earn target income R – 0.10R = $32,400 0.90R = $32,400 R = $32,400 ÷ 0.90 = $36,000 Direct costs $ 9,000 Indirect costs 23,400 Profit (0.40 9,000) 3,600 Bid price $36,000 4-22 (15–20 min.) Service industry, time period used to compute indirect cost rates. 1. Direct labor costs Variable costs as percentage of direct labor costs Variable overhead costs (Percentage direct labor costs) Fixed overhead costs Total overhead costs Total overhead costs as a percentage of direct labor costs Jan–March $400,000 April–June $280,000 90% 60% $360,000 300,000 $660,000 165% Job 332 Direct materials Direct labor costs Overhead allocated (variable + fixed) (165%; 180%; 170% of $6,000) Full cost of Job 332 July–Sept $250,000 60% $168,000 300,000 $468,000 $150,000 300,000 $450,000 167% 180% Oct–Dec $270,000 Total $1,200,000 60% $162,000 300,000 $462,000 $ 840,000 1,200,000 $2,040,000 171% Budgeted Overhead Rate Used Jan–March July–Sept Average Rate Rate Yearly Rate $10,000 $10,000 $10,000 6,000 6,000 6,000 9,900 $25,900 10,800 $26,800 10,200 $26,200 (a) The full cost of Job 332, using the budgeted overhead rate of 165% for January– March, is $25,900. (b) The full cost of Job 332, using the budgeted overhead rate of 180% for July– September, is $26,800. (c) The full cost of Job 332, using the annual budgeted overhead rate of 170%, is $26,200. 2. Budgeted fixed overhead rate based on annual fixed overhead costs and annual direct labor costs = $1,200,000 $1,200,000 = 100% Job 332 Direct materials Direct labor costs Variable overhead allocated (90%; 60%; of $6,000) Fixed overhead allocated Budgeted Variable Overhead Rate Used January–March July–Sept rate rate $10,000 $10,000 6,000 6,000 5,400 6,000 3,600 6,000 170% (100% of $6,000) Full cost of Job 332 $27,400 $25,600 (a) The full cost of Job 332, using the budgeted variable overhead rate of 90% for January–March and an annual fixed overhead rate of 100%, is $27,400. (b) The full cost of Job 332, using the budgeted variable overhead rate of 60% for July–September and an annual fixed overhead rate of 100%, is $25,600. 3. If Printers, Inc. sets prices at a markup of costs, then prices based on costs calculated as in Requirement 2 (rather than as in Requirement 1) would be more effective in deterring clients from sending in last-minute, congestion-causing orders in the January–March time frame. In this calculation, more variable manufacturing overhead costs are allocated to jobs in the first quarter, reflecting the larger costs of that quarter caused by higher overtime and facility and machine maintenance. This method better captures the cost of congestion during the first quarter. 4-24 (3545 min.) Job costing, journal entries. Some instructors may also want to assign Exercise 4-25. It demonstrates the relationships of the general ledger to the underlying subsidiary ledgers and source documents. 1. An overview of the product costing system is: INDIRECT COST POOL COST ALLOCATION BASE Manufacturing Overhead Direct Manufacturing Labor Costs Indirect Costs COST OBJECT: PRINT JOB DIRECT COST Direct Costs Direct Materials Direct Manuf. Labor 2. & 3. This answer assumes COGS given of $4,020 does not include the writeoff of overallocated manufacturing overhead. 2. (1) Materials Control Accounts Payable Control (2) Work-in-Process Control Materials Control (3) Manufacturing Overhead Control Materials Control (4) Work-in-Process Control Manufacturing Overhead Control Wages Payable Control (5) Manufacturing Overhead Control Accumulated Depreciation––buildings and manufacturing equipment (6) Manufacturing Overhead Control Miscellaneous accounts (7) Work-in-Process Control Manufacturing Overhead Allocated (1.60 $1,300 = $2,080) (8) Finished Goods Control Work-in-Process Control (9) Accounts Receivable Control (or Cash) Revenues (10) Cost of Goods Sold Finished Goods Control (11) Manufacturing Overhead Allocated Manufacturing Overhead Control Cost of Goods Sold 800 800 710 710 100 100 1,300 900 2,200 400 400 550 550 2,080 2,080 4,120 4,120 8,000 8,000 4,020 4,020 2,080 1,950 130 3. Bal. 12/31/2006 (1) Purchases Bal. 12/31/2007 Bal. 12/31/2006 (2) Direct materials (4) Direct manuf. labor (7) Manuf. overhead allocated Bal. 12/31/2007 Materials Control 100 (2) Issues 800 (3) Issues 90 Work-in-Process Control 60 (8)Goods completed 710 1,300 Bal. 12/31/2006 (8) Goods completed Bal. 12/31/2007 (10) Goods sold Cost of Goods Sold 4,020 (11) Adjust for over-allocation Bal. 12/31/2007 3,890 Indirect materials Indirect manuf. labor Depreciation Miscellaneous (11) To close 4,120 2,080 30 Finished Goods Control 500 (10) Goods sold 4,120 600 (3) (4) (5) (6) Bal. 710 100 Manufacturing Overhead Control 100 (11) To close 900 400 550 0 Manufacturing Overhead Allocated 2,080 (7) Manuf. overhead allocated Bal. 4,020 130 1,950 2,080 0 4-25 (20 min.) Job costing, journal entries, and source documents (continuation of 4-24). The analysis of source documents and subsidiary ledgers follows: 1. a. Approved purchase invoice b. dr. Materials record, “received” column cr. Accounts payable subsidiary ledger, account for creditor 2. a. Materials requisition record b. dr. Job cost records cr. Materials record, “issued” column 3. a. Materials requisition record b. dr. Department overhead cost records, appropriate column cr. Materials record, “issued” column 4. a. Summary of labor-time records or daily time analysis. This summary is sometimes called a labor cost distribution summary. b. dr. Job cost records dr. Department overhead cost records, appropriate columns for various classes of indirect labor cr. Wages payable subsidiary ledger 5. a. Special authorization from the responsible accounting officer b. dr. Department overhead cost records, appropriate columns cr. Accumulated depreciation subsidiary ledger 6. a. Various approved invoices and special authorizations b. dr. Department overhead cost records, appropriate columns 7. a. Use of an authorized budgeted manufacturing overhead rate b. dr. Job cost record 8. a. Completed job cost records b. dr. Finished goods records, received column cr. Job cost record, completed column 9. a. Approved sales invoice b. dr. Accounts receivable subsidiary ledger cr. Sales ledger, if any 10. a. Costed sales invoice b. cr. Finished goods records, issued column 4-31 11. a. Special authorization from the responsible accounting officer b. Subsidiary records are generally not used for these entries (1520 min.) Service industry, job costing, law firm. 1. INDIRECT COST POOL COST ALLOCATION BASE COST OBJECT: JOB FOR CLIENT DIRECT COST Legal Support Professional Labor-Hours Indirect Costs Direct Costs } Professional Labor 2. Budgeted professional = Budgeted direct labor compensation per professional labor-hour direct cost rate Budgeted direct labor-hours per professional $104,000 = 1,600 hours = $65 per professional labor-hour Note that the budgeted professional labor-hour direct-cost rate can also be calculated by dividing total budgeted professional labor costs of $2,600,000 ($104,000 per professional 25 professionals) by total budgeted professional labor-hours of 40,000 (1,600 hours per professional 25 professionals), $2,600,000 40,000 = $65 per professional labor-hour. 3. Budgeted total costs in indirect cost pool Budgeted total professional labor-hours $2,200,000 = 1,600 hours 25 $2,200,000 = 40,000 hours = $55 per professional labor-hour Budgeted indirect = cost rate 4. Direct costs: Professional labor, $65 100; $65 150 Indirect costs: Legal support, $55 100; $55 150 Richardson Punch $ 6,500 $ 9,750 5,500 $12,000 8,250 $18,000 4-32 (25–30 min.) Service industry, job costing, two direct- and indirect-cost categories, law firm (continuation of 4-31). Although not required, the following overview diagram is helpful to understand Keating’s job-costing system. INDIRECT COST POOL COST ALLOCATION BASE General Support Secretarial Support Professional Labor-Hours Partner Labor-Hours COST OBJECT: JOB FOR CLIENT DIRECT COST } Indirect Costs Direct Costs Professional Associate Labor Professional Partner Labor 1. Budgeted compensation per professional Divided by budgeted hours of billable time per professional Budgeted direct-cost rate *Can also be calculated as Professional Partner Labor $ 200,000 Professional Associate Labor $80,000 ÷1,600 $125 per hour* ÷1,600 $50 per hour† Total budgeted partner labor costs Total budgeted partner labor - hours $200,000 5 $1,000,000 = 1,600 5 8,000 † Can also be calculated as = Total budgeted associate labor costs Total budgeted associate labor - hours $80,000 20 $1,600,000 = 1,600 20 32,000 2. Budgeted total costs Divided by budgeted quantity of allocation base Budgeted indirect cost rate = General Secretarial Support Support $1,800,000 $400,000 ÷ 40,000 hours ÷ 8,000 hours $45 per hour $50 per hour = $125 = $ 50 3. Richardson Punch Direct costs: Professional partners, $125 60; $125 30 Professional associates, $50 40; $50 120 Direct costs Indirect costs: General support, $45 100; $45 150 Secretarial support, $50 60; $50 30 $7,500 2,000 $3,750 6,000 $ 9,500 4,500 3,000 $ 9,750 6,750 1,500 7,500 $17,000 Indirect costs 8,250 $18,000 Total costs 4. Single direct - Single indirect (from Problem 4-31) Multiple direct – Multiple indirect (from requirement 3 of Problem 4-32) Difference Richardson Punch $12,000 $18,000 17,000 18,000 $ 5,000 undercosted $ 0 no change The Richardson and Punch jobs differ in their use of resources. The Richardson job has a mix of 60% partners and 40% associates, while Punch has a mix of 20% partners and 80% associates. Thus, the Richardson job is a relatively high user of the more costly partner-related resources (both direct partner costs and indirect partner secretarial support). The refined-costing system in Problem 4-32 increases the reported cost in Problem 4-31 for the Richardson job by 41.7% (from $12,000 to $17,000). 4-34 1.a. (15 min.) Normal costing, overhead allocation, working backward. Manufacturing overhead allocated = 200% × Direct manufacturing labor cost $3,600,000 = 2 × Direct manufacturing labor cost Direct manufacturing labor cost = b. $3,600,000 = $1,800,000 2 Total manufacturing = Direct material + Direct manufacturing + Manufacturing cost used labor cost overhead allocated $8,000,000 = Direct material used + $1,800,000 + $3,600,000 Direct material used = $2,600,000 2. Work in Process + Total manufacturing cost = 1/1/2007 Cost of goods manufactured + Work in Process 1/1/2007 Denote Work in Process on 12/31/2007 by X $320,000 + $8,000,000 = $7,920,000 + X 4-40 1. X = $400,000 (20 min.) Job costing, contracting, ethics. Direct manufacturing costs: Direct materials Direct manufacturing labor Indirect manufacturing costs, 150% $6,000 Total manufacturing costs $25,000 6,000 $31,000 9,000 $40,000 Aerospace bills the Navy $52,000 ($40,000 130%) for 100 X7 seats or $520 ($52,000 100) per X7 seat. 2. a Direct manufacturing costs: Direct materials Direct manufacturing labora Indirect manufacturing costs, 150% $5,000 Total manufacturing costs $25,000 5,000 $30,000 7,500 $37,500 $6,000 – $400 ($25 16) setup – $600 ($50 12) design Aerospace should have billed the Navy $48,750 ($37,500 130%) for 100 X7 seats or $487.50 ($48,750 100) per X7 seat. 3. The problems the letter highlights (assuming it is correct) include the following: a. Costs included that should be excluded (design costs) b. Costs double-counted (setup included as both a direct cost and in an indirect cost pool) c. Possible conflict of interest in Aerospace Comfort purchasing materials from a family-related company Steps the Navy could undertake include the following: (i) Use only contractors with a reputation for ethical behavior as well as quality products or services. (ii) Issue guidelines detailing acceptable and unacceptable billing practices by contractors. For example, prohibiting the use of double-counting cost allocation methods by contractors. (iii)Issue guidelines detailing acceptable and unacceptable procurement practices by contractors. For example, if a contractor purchases from a family-related company, require that the contractor obtain quotes from at least two other bidders. (iv) Employ auditors who aggressively monitor the bills submitted by contractors. (v) Ask contractors for details regarding determination of costs.