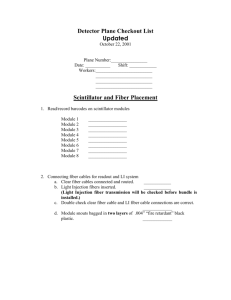

Detector plane check out list

advertisement

Detector Plane Horizontal Checkout List Modified (wlb) November 28, 2001 Plane Number:________________ Date: ___________ Shift: ____________ Crew Names: _________________________ _________________________ _________________________ _________________________ Scintillator and Fiber Placement 1. Read scintillator modules numbers. (Module one is the bottom module, the one nearest to the rollers.) Module 1 Module 2 Module 3 Module 4 Module 5 Module 6 Module 7 Module 8 UMN_______________A UMN_______________B CIT_________________ CIT_________________ CIT_________________ CIT_________________ UMN_______________B UMN_______________A 2. Connecting fiber cables for readout and LI system a. Clear fiber cables connected and routed. ____________ b. Light Injection fibers inserted. ____________ (Light Injection fiber transmission will be checked before bundle is installed.) c. Double check clear fiber cables and LI fiber cable connections are correct. d. Module snouts bagged in two layers of .004 inch “fire retardant” black Plastic. Module Checkout 3. Module Transmission Testing: Beginning 10/15/01 we will be doing transmission tests only on modules that have 2 “bad” fibers already observed in their module maps or modules that we suspect have been damaged in handling. Module maps must be reviewed before scintillators are place on the steel. Module transmission test results: Module 1 Module 2 Module 3 Module 4 Module 5 Module 6 Module 7 Module 8 transmission______ transmission______ transmission______ transmission______ transmission______ transmission______ transmission______ transmission______ sigma_______% sigma_______% sigma_______% sigma_______% sigma_______% sigma_______% sigma_______% sigma_______% 4. Light Injection Cable checkout: The following two procedures must be accomplished as part of the light leak checkout procedure. These are done after the clear fiber cables are installed on both sides of the scintillator module. Fiber 1 position is near the small dowel . Part 1: Shine a flashlight down one end of the clear fiber. Check for light on the cable attached to the far side of the module. The light should start at the small dowel pin-hole and be continuous across the connector for 20 (CIT module) or 28 (UMN modules) fibers. Broken fibers will appear dark. If the first fiber is dark, you should expect the first fiber in test 2 to be dark also. If light shines beyond 20 for CIT or 28 fibers for UMN, contact the physicist shift leader. Part 2: Slide the special black out connector and rubber band over one end of the clear fiber. Make sure the small dowel hole on the cable and the black out connector face each other. Shine light on the hole in the black out connector. Light should appear in the fiber 1 position on the far end of the cable. If the light does not appear anywhere and fiber one was dark in test one, then you should expect to find that fiber one is broken. Have a physicist shift leader check the module map. If the light appears in some position other than position 1, either a clear fiber cable is mounted backwards or one of the cables has not been built correctly. Contact the physicist shift leader. Completed Part 1___________ 5. Light Leak Checkout. Module Light Leak test(noise rate Hz): East___ or West____ Module 1(3.3KHz) Module 2(5.2KHz) Module 3(4.2KHz) Module 4(4.3KHz) Module 5(4.3KHz) Module 6(4.3KHz) Module 7(5.2KHz) Module 8(3.3KHz) ______ ______ ______ ______ ______ ______ ______ ______ Part 2 ______________ Note leak location here AND on the PLANE MAP. _______________________________ _______________________________ _______________________________ _______________________________ _______________________________ _______________________________ _______________________________ _______________________________ 6. Final tie down of clear fibers in the stay clear zone before raising module. _____ 7. Route cables outside the radial axial bolts at the plane “ears”. 8. Final visual inspection and certification that plane is ready for hanging. _____ ______ Vertical Tasks/Checkout 9. Uncoil clear fiber cable and route to the cattle guard. _________________ 10. Connect clear fiber cables to appropriate MUX box. __________________ 11. Every fourth plane Light leak check clear fiber MUX box connections.____