Keeping it Simple: Customizing Process Chromatography

advertisement

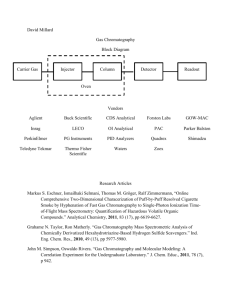

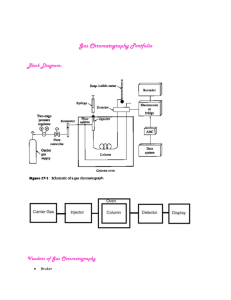

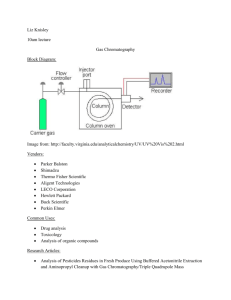

HOW BIOTECH MANUFACTURERS CAN IMPROVE CHROMATOGRAPHY THROUGH CUSTOMIZATION By Iggy Gyepi-Garbrah (Pall Europe Ltd.) & Ian Sellick (Pall Corporation) Biotech manufacturers use chromatography for a number of steps during downstream drug processing, from initial protein capture and separation, to final polishing. While it is the most powerful purification tool available in the industry, it is not always used efficiently. Manufacturers today are faced with new and changing production variables in developing new drug therapies. Bio-molecules harvested for processing are becoming more complex, and they come from increasingly diverse sources. At the same time, manufacturers are looking to simplify purification steps in an effort to streamline production and improve process economics. This column offers some recommendations to manufacturers hoping to achieve greater process efficiencies. The best way to simplify and economize is to select a customized purification protocol that works best for a particular system and process. For each novel and variable production method there is a set of particular separation and purification challenges, and manufacturers need to consider the whole spectrum of production options. Choosing independent and knowledgeable suppliers is critical in order to get the widest variety of platforms available. DIVERSE OPTIONS FOR DIVERSE CELLS New monoclonals are being produced from bacterial cells, mammalian and nonmammalian animal cells, in transgenic milk, and even from transgenic plant sources such as corn and tobacco. If your system is designed for harvesting cells from Chinese hamster ovaries, you need to use different processing methods to harvest cells from duckweed plants. Just as there is a diversity of cells to process, there is a diversity of chromatography resins, columns, and membranes available. Manufacturers need to have access to as many of these options as possible in order to achieve the most cost-effective and efficient process. The expertise of a chromatography manufacturer is important, from selecting the right column, the correct resin, to efficiently packing resin in the column. New chromatography technologies, including recent improvements in automated column packing techniques, are helping to reduce cycle costs and improve throughput. Disposable chromatography membrane capsules and cartridges offer another option when used alongside column chromatography, particularly for removing residual contaminants such as DNA and host cell proteins. Because disposability eliminates cleaning and cleaning validation, this saves considerable time and labor. Membranes have also demonstrated effective virus removal, and they offer high throughput processing that would otherwise require enlarging column systems, at considerable capital expenditure. INTEGRATING MULTIPLE CHROMATOGRAPHY STEPS Manufacturers have long been integrating different types of chromatography into processing. In some instances, up to six separate chromatography steps can be incorporated into a single purification cycle. Most monoclonal therapies are manufactured using a cell suspension in a reactor. In this feed stream there is the potential to produce residual DNA, RNA, endotoxins, host cell proteins, and also viruses. These contaminants need to be removed to the lowest detection levels required by regulatory authorities for a finished product. Figure One offers a schematic of the general steps required for processing a generic monoclonal antibody. Chromatography is incorporated mainly into downstream processing, which basically encompasses all steps following cell harvesting. Chromatography is used first for clarification, capture and purification. It can also be incorporated in the final product formulation stage. The initial chromatography capture step may use a Protein A affinity resin. Protein A separation binds the target antibody while significantly reducing the bulk of unwanted process volume. In monoclonal antibody purification, the industry trend is to use smaller columns for the initial capture step, and to recycle Protein A resin for as many runs as possible. This is due to the expense of Protein A resins, which can cost upwards of US$8,500 per liter; by contrast, ion exchange resins used in later states of processing are a tenth of the cost, at upwards of $750 per liter. A 200 liter column of Protein A resin can cost an operator approximately $1.7 million dollars to pack. Recycling is therefore extremely important for process economics; in many cases a Protein A column can be cycled up to 300 or even 400 times. After the initial capture step, the monoclonal is eluted off of the Protein A column. The solution may then go into a holding vessel prior to diafiltration (to remove salt), and then to additional purification steps, which may be in reverse phase, or ion- exchange. The diafiltration step can be eliminated if a hydrophobic interactive chromatography (HIC) resin is used following initial capture. HIC resins are loaded at high salt concentrations, which are usually the same conditions under which Protein A is eluted. This potentially saves thousands of dollars per batch in processing costs, especially for large bulk systems. RESINS, COLUMN PACKING AND SCALE-UP For a truly customized solution, a chromatography column supplier should help manufacturers select the best resin media appropriate for a given process. To maximize flexibility, a supplier should furnish information on as many different resins as possible. This should include analyses of flow rates, densities, slurry mixes, as well as thorough packing instructions and results of previous packing studies. An independent column manufacturer can usually provide the above information for a wide spectrum of resin options. “Pack-in-Place” column packing technology is becoming more widely used as it helps ensure consistent column packing and unpacking. By automating packing procedures, “pack-inplace” systems help eliminate the human variables involved in column packing. Recent innovations in packing include the use of ultrasound technology to monitor the bed build as resin is pumped into a column. Ultrasound can detect bed construction, formation of voids, bed compression, and the position of the mobile phase in the column. Although the use of ultrasound for chromatography has not yet been commercialized, it is currently being beta-tested at the manufacturing scale, and it promises to provide manufacturers a novel method of controlling the rate of bed formation, and optimized resin performance. Another important consideration is linear scalability of the column design, which is critical for moving a product from small to medium and large scale processing. The best column design maintains all operational parameters at constant levels regardless of column size. It is important for manufacturers to realize that many columns on the market have different designs as the column size increases, and are therefore not linearly scalable. Columns and valves should be engineered to scale together; as columns increase in size, packing valves need to scale up as well in proportion. However, for many column manufacturers with a pack-in-place system, the packing valve is the same size on differently sized columns. If a column is doubled in size for processing, a packing valve needs to be scaled to accommodate a four- or even eight-fold increase in flow rates. A valve set at a fixed flow rate cannot cope with such an increase. MEMBRANE CHROMATOGRAPHY FOR DNA AND VIRUS REMOVAL A relatively new step that has been integrated into processing is disposable ion exchange chromatography membranes. Membranes have been particularly effective as a polishing step to remove residual levels of large molecules such as DNA. Membranes offer enhanced processing capabilities because adsorption and flow rates are not limited by diffusive flow into pores. Because of this and their large (>0.8um) pore sizes, membranes offer higher capacities (>10X) and higher flow rates (>50X) when compared to column chromatography. To achieve the same flow rates as membrane cartridges, column sizes need to be substantially increased at great capital expense. Membrane cartridges are disposable, which means that cleaning and cleaning validation steps are eliminated, saving substantial labor time as well as buffer costs. A more recent processing option has been the use of membrane chromatography for virus removal. Viruses can be removed through either inactivation or removal, and while in many instances effective removal of other contaminants can occur in a single step, acceptable titer reductions can usually only be achieved by using a combination of technologies, including chromatography, in an orthogonal process. A Q-membrane chromatography cartridge will remove most undesirable contaminants, including residual DNA, host cell proteins, and endotoxins. This same Q-membrane has also demonstrated high levels of effectiveness in binding viruses for removal. The adsorption capability of membrane chromatography has been well documented. For example, Q chemistry membranes have demonstrated binding efficiencies of 1013 adenovirus particles per ml bed volume of membrane. Removal of virus from flow-through (log10) Recovery of input virus* MuLV PRV PPV HAV BVDV (%) As Figure Two shows, membrane chromatography has also demonstrated effective removal of model viruses such as porcine, parvovirus, hepatitis A virus, murine leukemia virus and pseudorabies virus at removal efficiencies between 104 and 107. Model viruses range in size and complexities. If a manufacturer’s data demonstrate removal of these model viruses, it is safe to assume that the same purification protocol will work for other similar viruses. CONCLUSION Manufacturers have a diversity of chromatography options at their disposal, and new technologies can be utilized in a number of processing stages. When it comes to chromatography, one size does not fit all, and process economics today require operators to integrate customized steps into their production. In choosing a chromatography vendor, manufacturers need to consider the full range of options, and should select a partner who offers the widest flexibility and expertise possible. Author Contact Information: Iggy Gyepi-Garbrah European Marketing Manager for Chromatography Pall Europe Ltd. Europa House Havant Street - Portsmouth Hampshire, England PO1 3PD Tel: +44 23 9230 2542 Fax: +44 23 9230 2510 Email: Iggy_Gyepi-Garbrah@pall.com Ian Sellick Director of Marketing Pall BioPharmaceuticals 2200 Northern Blvd. East Hills, NY 11548-1289 Tel. 516.801.9497 Fax 516.801.9548 Email: ian_sellick@pall.com.