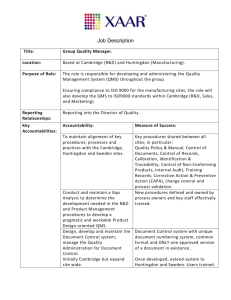

Corporate Quality Assurance Manager

advertisement

Compass Manufacturing Compass Components Services Corporate Quality Assurance Manager Compass Components is an ISO certified, committed partner to (Fortune 500) companies. Compass Components provides custom equipment, systems design, engineering, contract manufacturing, system integration services, and electronic component distribution. Since 1979 our manufacturing, engineering, design and distribution capabilities have fulfilled the needs of various industries, including transportation, industrial, and semiconductor. With over 200 employees, we have multiple facilities located regionally throughout the West, including Silicon Valley, Northwest and the Southwestern US. This has enabled us to be a leading provider of design/engineering services, integration, distribution, complex electronic assembly, and cables & harnesses. This vertically integrated approach empowers Compass to address all customer requirements from concept design through final production, including system integration. Compass is currently seeking a Corporate Quality Assurance Manager for our Fremont location. This managerial position will report directly to the company president and have responsibility for establishing, directing, and maintaining the corporate quality management system (QMS) that promotes customer satisfaction and has a positive impact on the financial performance of the company. This individual will champion continuous improvement efforts and defect reduction initiatives to improve on the QMS, and implement quality improvement activities as appropriate to raise the performance of the company’s products and services. Additionally, this role will further develop the system to meet additional industrial certification requirements necessary to capture other market sectors. This position includes but not be limited to the following duties; Develop, implement, manage, and integrate a QMS for all manufacturing facilities. Further develop the QMS system to meet additional industrial standards that will broaden our customer base into new manufacturing disciplines. Serve as the primary quality resource for reporting process deficiencies and facilitating continuous process improvements. Help design, and document procedures for process control, process improvement, testing, and inspection. Establish and implement performance metrics for monitoring system effectiveness and to enable managers to make sound product quality decisions based on past trends. (ie. RMA, OTD, Internal Non-Conformances, etc.) Train personnel on conducting root cause analysis and other problem solving activities to identify effective corrective actions and process improvements. Help improve supplier relationships by establishing supplier quality requirements. Interface with supplier and customer quality representatives concerning problems with quality control, and assure that effective corrective action is implemented. Monitor supplier performance and establish criteria and rating system for critical suppliers, and process for disengagement when necessary. Interact with customers to identify opportunities to improve quality and establish feedback with manufacturing and training personnel. Participate in internal and external quality audits. Conduct quarterly management review meetings on quality issues, trends and losses. Develop process certification standards and assist in implement Plan, promote and organize training activities related to product consistency and quality. Consistent on-going employee communication. Maintain the company’s Quality Management System. Interface with all customers and departments on quality issues. Requirements B.S. Degree preferred. Ten years Quality experience in related field. Strong background in developing QMS to meet AS9100 & ISO 13485. Minimum 5 years managerial level experience. Must possess strong leadership and communication skills. Proficient in Microsoft windows. EPICOR software or any similar manufacturing operation software.