City of Fargo Solid Waste Maintenance Facility Parking Lot

advertisement

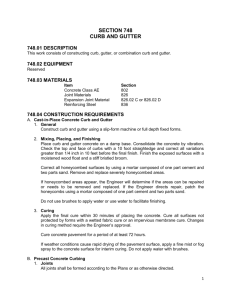

City of Fargo Solid Waste Maintenance Facility Parking Lot - Innovation As parking lots go, this project may not seem to meet the criteria of an award winning project. But there is more than meets the eye when it comes to technology. What makes this project stand apart is the innovation brought to the constructability side of pavements. And what, we might ask, can be identified as possibly innovative for the construction of parking lots? Yes, only subtle things can be found, but enormously meaningful for the business of construction. And there is a story to this project being the first in North Dakota to use the viscosity modifier admixture for finishing enhancement. The story starts with solving problems for our customers. Knife River has the resources to bring much to the table, being a national player in ready mix concrete. Jim Erbstoesser from the Fargo plant related the story of problems with tearing of slip formed curb & gutter being placed this past summer. After discussion of the problem around the office, Jeff Eberhardt, Fargo Manager of Knife River Materials suggested the introduction of a small amount of viscosity modifier supplied by GRT Admixtures to improve the texture of the mix. When Erbstoesser called the Curb & Gutter Foreman to evaluate a certain load of concrete on the way to his job, the Foreman noted a marked improvement, completely eliminating the tearing. After more experimentation, it was decided to use the viscosity modifier to improve finishing of pavements, especially with roller screed finishing. Thereby, this parking lot project was the first to receive the enhanced mix to improve finishing. The Concrete Foreman on this project noted an immediate improvement in finishing, with the beneficial reduction in effort to achieve the smooth surface with a minimum of effort. The outcome of the improved finishing capability is an immediate benefit for all who construct concrete pavements or curb & gutter. The first obvious benefit is the reduction in effort, which translates to a reduction in cost to construct. The second obvious benefit relates to the ability to do more work with less manpower and assets. A third benefit is providing the customer with a higher quality surface finish compared to traditional concrete mixes. Knife River Materials continues to provide innovation to the concrete industry highlighted by examples provided by this Innovative Award application.