PRESENTATION NAME

advertisement

JOB HAZARD ANALYSIS & RISK

ASSESSMENT FORM

Nor Aini Burok

JOB HAZARD ANALYSIS & RISK

ASSESSMENT FORM

(until June 2013)

JOB SAFETY ANALYSIS & RISK

ASSESSMENT FORM

(From Sept 2013)

Nor Aini Burok

ACCIDENT IN LAB 1

• A fatal accident happened in an organic chemistry laboratory at

the University of California, Los Angeles (UCLA) in late December,

2008.

• A research assistant was using a syringe to transfer about

50 mL of a pyrophoric chemical (a substance that catches fire

spontaneously once exposed to air), tert-butyl lithium, dissolved

in pentane, a flammable solvent. The plunger suddenly came apart

from the syringe barrel, causing the pyrophoric chemical to spew

onto the hands and body of the researcher and catch fire.

• Even though the fire was finally put out by other laboratory

workers, the researcher suffered second to third-degree burns to

over 43% of her body. She died in January 2009 due to the burns

and the resulting complications, after 18 days in the hospital.

ACCIDENT IN LAB 2

• One student, Preston Brown, 29, was

seriously injured in the Jan. 7, 2010

accident and remains in critical condition,

• Brown received severe burns and

lacerations to his face and hands when a

mixture of nickel hydrazine perchlorate

exploded during the afternoon accident

in Texas Tech's chemistry building,

according to a police report. University

officials told CSB the accident involved

the detonation of a high-energy metal

compound.

F

I

N

D

I

N

G

S

1

2

3

• Inadequacy of hazard identification

& risk assessment.

• No or inadequacy safety training .

In any case, there was no safety

training record available.

• Inadequate supervision and

unsatisfactory safety management.

POLICY FOR FYP

AT MICET

ALL FYP

STUDENTS

COMPLETE

JOB SAFETY

ANALYSIS &

RISK

ASSESSMENT

TO

ELIMINATE

AND

MINIMIZE

RISK OF

ACCIDENT IN

LABORATORY

JOB SAFETY ANALYSIS PROCESS FLOW CHART.

Wk 1 - 4

Wk 4

Wk 5

• FINAL YEAR PROJECT Coordinator (from each section) will submit list of FYP

student for respective semester to SAFETY AND HEALTH OFFICER.

• Student will attend Final year project briefing in Wk 2 (latest).

• Student will submit proposal for supervisor evaluation.

• Student will confirm the method & chemical used in their FYP.

• Student will prepare Job Safety Analysis[DO NOT FORGET TO DISCUSS WITH

TECHNICIAN IN-CHARGE (TIC) & YOUR SUPERVISOR AND OBTAIN THEIR

APPROVAL].

• Submission of JSA to receptionist and stamped with DATE RECEIVED>

• Student will submit completed Job Safety Analysis for approval to Safety and

Health Officer (SHO).

JOB SAFETY ANALYSIS PROCESS FLOW CHART

cont….

Wk 6

TO

Wk 8

• SHO will evaluate the completed Job Safety Analysis.

• Once approved, notification will be done by memo on the

soft board/ SMS.

• Prior starting the experiment, student must submit the

ORIGINAL Job Safety Analysis to theTIC of the main (mostly

used) laboratory use. [NO JSA, TIC WILL DISALLOWED

STUDENT TO USE OF THE LABORATORY].

• Student need to submit a copy of Job Safety Analysis to

another TECHNICIAN in-charged in another laboratory [if

more than one lab is going to be used].

JOB SAFETY ANALYSIS PROCESS FLOW CHART

cont….

TO

END OF FYP

DURATION

• JOB SAFETY ANALYSIS MUST ALWAYS

AVAILABLE IN THE LABORATORY FOR

REFERENCE [specially IN EMERGENCY

SITUATION].

• AT ANY TIME, IF WORK AFTER OFFICE HOUR IS

REQUIRED. YOU MUST OBTAIN THE APPROVAL

FROM HEAD OF SECTION & SAFETY AND

HEALTH OFFICER PRIOR STARTING THE WORK

BY COMPLETED THE FORM IN SECTION 8a.

JSA & RA PREPARATION AND APPROVALFLOW CHART

1. Confirm title & supervisor

6.PUBLICATION ON NOTICE BOARD OR

COMMUNICATED VIA SMS .

2. Prepare proposal & confirm

method with supervisor

7. COLLECTION OF JSA & RA

FORM

3. Prepare JSA & RA

8. SUBMISSION OF ORIGINAL

APPROVED FORM TO TECHNICIAN

With technician &

supervisor review &

approval

4. Submission of JSA & RA form to

receptionist.

9. ANY CHANGES (Like method or

etc)

Latest by Wk 5

/Sem 1

5. Approval of JSA & RA Form

10. WORK AFTER OFFICE HOUR

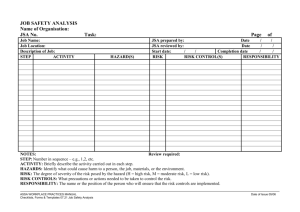

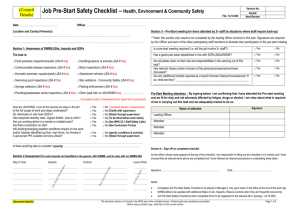

JOB SAFETY

ANALYSIS & RA

FORM

1.

2.

3.

•

1.

2.

3.

4.

5.

JSA & RA Form.doc

Material Safety Data Sheet

(MSDS)

FIRST SCHEDULE of

ENVIRONMENTAL QUALITY

(SCHEDULED WASTES)

REGULATIONS 2005.

6.

7.

8.

9.

10.

11.

Consist of 11 parts.

Title of procedure / experiment.

Name of author & contact number.

Name of supervisor { & co-supervisor}.

Method / Procedure.

Hazard Identification and Control measures

a. Substances used which have potential to cause

harm; i.e potential hazards.

b. Equipment used in the procedure which may cause

harm

c. Laboratoy / laboratories required

d. First Aid and Fire fighting equipment available

Disposal routes for waste materials

Risk assessment and precaution to be taken ( in

statement)

Level of supervision and suitability for out-of-work

a. Out-of work approval

b. Emergency contact number

Evidence of Review and checked by laboratory technician

and supervisor.

Details of other student involved in the

project/procedure

Review Section [TO BE FILLED BY POSTGRADUATE ONLY].

Any

Question ?