HP Carbamate Pump P-102A Failure (Task Force Report)

advertisement

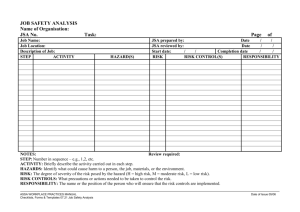

JOB SAFETY ANALYSIS A SUCCESSFUL EXPERIENCE IN FAUJI FERTILIZER COMPANY Prepared by: Usman Sharif Taufeeq Arshad OUTLINE FFC Safety Culture & Commitment Safety Indicators Job Safety Analysis Steps for JSA Benefits of JSA JSA-A successful experience in FFC SAFETY CULTURE Safety is our top priority We have 23.46 million man-hours without LTI Safety is main consideration for plant operation / maintenance FFC is certified for • Quality management system ISO 9001:2008 • Occupational health & Safety Assessment Series OHSAS 18001:2007 • Environment Management System ISO 14001:2004 Our safety goal is human and equipment safety FFC SAFETY COMMITMENT Individual’s Mistake Considering the link between Accident organizational failures and mistakes, Causes Organizational ‘SAFETY as a goal’ is mandatory FFC’S COMMITMENT Lapses SAFETY INDICATORS • Measurements of past incidents, successes and failures • Prediction of future performance and commitment to achieve safe execution of the job • As Job Safety Analysis (JSA) is also a pro-active approach, it therefore falls in the category of leading indicators JOB SAFETY ANALYSIS (JSA) OSHA Standard 3071 pertains to Job Safety Analysis. “It is a technique that focuses on job tasks as a way to identify hazards before they occur. It focuses on the relationship among the worker, task, tools and work environment” JOB SAFETY ANALYSIS (JSA) JSA should be conducted by a group of experienced personnel from all concerned disciplines JSA team should not conduct the analysis in isolation; all concerned employees to be involved in the process JSA should be conducted in the same environment in which the job is planned for execution JSA team should come up with practical control measures and avoid mentioning vague instructions JSA will be useful only when all the defined control measures are implemented in letter and spirit BASIC STEPS FOR JSA 1- Select a job 1- SELECTION OF JOB JSAs are not feasible For routine jobs For jobs defined too broadly, for example, ‘overhauling of urea plant centrifugal pumps’; For jobs defined too narrowly, for example, ‘dismounting of anti friction bearings from the shaft.’ 1- SELECTION OF JOB • Factors to be considered in setting a priority for analysis of jobs include: – Accident frequency and severity – Newly established jobs – Infrequently performed jobs BASIC STEPS FOR JSA 1- Select a job 2- Break the job into sequence of steps 2- SEQUENCE OF STEPS A ‘job step’ is defined as a segment of the operations necessary to advance the work. • All critical steps should be written down • The sequence of steps must be maintained • The breakdown of steps should be discussed among all the participants (always including the worker) when completed. BASIC STEPS FOR JSA 1- Select a job 2- Break the job into sequence of steps 3- Identify potential hazards & associated risk level 3- HAZARDS & RISK LEVELS HAZARD any source of potential damage or adverse health effects on something or someone under certain conditions at work. RISK is the chance or probability that a person or property will be harmed to a certain level, if exposed to a hazard. HAZARDS CLASSIFICATION Biological Bacteria, viruses, insects, animals Chemical Ergonomics Toxic properties of the chemical. improper set up of workstation HAZARDS Electrical Noise Excavation Electric shock, electric fire Hearing loss, inability to communicate Soil collapse in trench / pit HAZARDS To help identify potential hazards, the team members should follow a questioning attitude and may use questions such as: • Can any body part gets caught in or between objects • Is the temperature of working area is comfortable • Does any particular tool or machine pose any hazard • Can the worker slip, trip, or fall in the working area • And so on ------ RISK LEVELS Risk reduction measures should be HIGH implemented or activity to be suspended / restricted. Considerable resources to be allotted Additional MEDIUM controls are taken considering the cost, the risk level to be lowered to an acceptable level No additional controls are required LOW unless they can be implemented at very low cost (in terms of money, time and effort RISK LEVELS JOB NATURE HAZARDS EXPOSURE HIGH RISK LEVEL TENDENCY TO FOLLOW SHORT CUTS TENDENCY TO LOSE CONCENTARTION HUMAN NATURE BASIC STEPS FOR JSA 1- Select a job 2- Break the job into sequence of steps 3- Identify potential hazards & associated risk level 4- Determine control measures to mitigate hazards 4-CONTROL MEASURES 4- CONTROL MEASURES Elimination / substitution • Wiping off the spilled oil from the floor • Using a brass hammer instead of conventional steel hammer on the natural gas line. Engineering Controls • Incorporating ventilation systems to control fumes • Installing an acoustic hood on the blower for abating the sound Administrative Controls • Altering schedules to day time when the hazard is less likely to occur • Strict compliance of work permit procedures Personal protective equipment (PPE) • Using engineering or administrative controls, if a hazard cannot be reduced to an acceptable risk level, appropriate PPEs should be used BENEFITS OF THE JSA Provides a written step wise procedure, which improves communication between workers and supervisors. Provides minor details / guidance in the management of the hazards and risks that are embedded in the job. Unveils the latent hazards of the job, this can be best achieved if experienced personal of all discipline taken on board. JSA can be a valuable tool for the training of new inductees JSA can be used to help refine safe work procedures described in safety manuals or standard operating procedures. JSA- A SUCCESSFUL EXPERIENCE SAFETY EXCELLENCE ROUTINE FOR MAJOR JOBS/ INFREQUENT JOBS THE FIRST JSA WAS CARRIED OUT IN YEAR 2007 ZERO SAFETY INCIDENT IN ALL CRITICAL / INFREQUENT JOBS JSA- A SUCCESSFUL EXPERIENCE JOB SAFETY ANALYSIS Department Section/ Unit Area Equipment Production-II Ammonia-II 43 C-4321 Job C-4321, Replacement of damaged portion (6th, 7th & 8th shell course) Required personal Protective Helmet, Safety Glasses, Harness, Ammonia Escape Mask, Leather bags, Required Machines / Crane, Trailer, Grinders, Spanners, Hammer, welding tools, Chain blocks, Tools Shackles, Slings, Tacking Cleats Conducted by: abc / xyz Risk Level High Medium Low Hazard Level: JSA- A SUCCESSFUL EXPERIENCE Sequence of Basic Job Steps Possible Hazards Risk Level Corrective Measure Pre – Turnaround Activities • • Pre turnaround scaffolding Removal of permanent plate forms & Monkey Ladder(s) - Falling hazard - Falling Object - Ammonia release - Falling Object - Falling of platform during rigging - Ammonia release Medium Medium Use Safety harness. Use Tie strip on spanners against falling Use bags for transferring Joints Take ammonia mask while going for any job at height Use Lan yard with spanners to avoid falling Halt rigging if wind velocity exceeds 25 km/hr Hazard Level: JSA- A SUCCESSFUL EXPERIENCE Turnaround (Field) Activities • Rigging of upper portion of C-4321 - Falling of column Medium during rigging 2) Inspect all rigging hardware 1) Follow confined space entry 1) Confined space procedure. entry. • Tacking/weldin g of Upper portion with lower portion 2) Use ELCB with electric board 2) Electric shock while using electric grinder. 3) Disc/metal particles fly off. 4) Fire hazards 1) Follow the rigging plan 3) Make enclosure for capturing Medium grinding/welding spatters 4) Remove flammable material before start of hot job. 5) Use healthy welding equipment & associated hardware JSA- A SUCCESSFUL EXPERIENCE Pre arrangements Safe rigging