Alexandrina - checklist - WHS Job Pre Start Safety Checklist Nov 2014

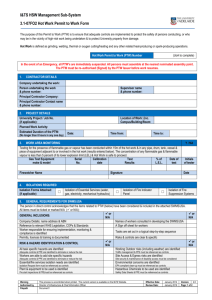

advertisement

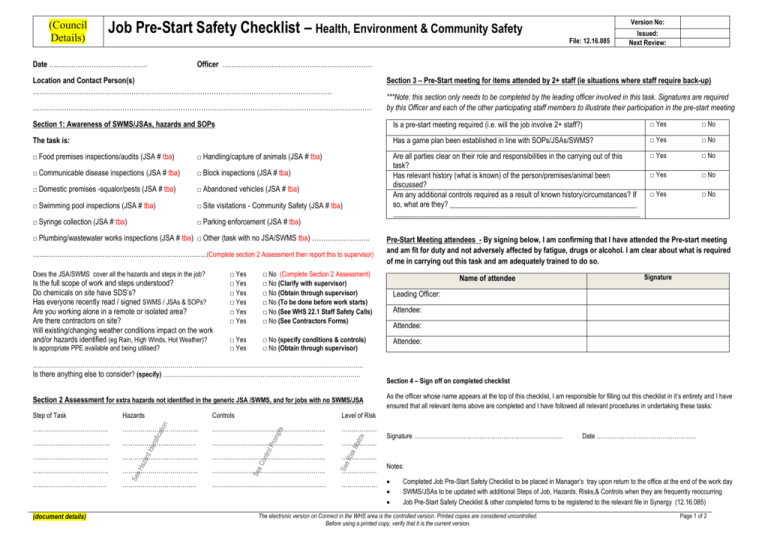

(Council Details) Job Pre-Start Safety Checklist – Health, Environment & Community Safety Version No: File: 12.16.085 Date …….………………………………. Issued: Next Review: Officer …………………….…………………………………… Location and Contact Person(s) ……………………………………….………………….………………….………………….…………………. Section 3 – Pre-Start meeting for items attended by 2+ staff (ie situations where staff require back-up) ……………………………………………………………………………………………………………………………………. ***Note: this section only needs to be completed by the leading officer involved in this task. Signatures are required by this Officer and each of the other participating staff members to illustrate their participation in the pre-start meeting Section 1: Awareness of SWMS/JSAs, hazards and SOPs Is a pre-start meeting required (i.e. will the job involve 2+ staff?) □ Yes □ No The task is: Has a game plan been established in line with SOPs/JSAs/SWMS? □ Yes □ No Are all parties clear on their role and responsibilities in the carrying out of this task? Has relevant history (what is known) of the person/premises/animal been discussed? Are any additional controls required as a result of known history/circumstances? If so, what are they? __________________________________________________ __________________________________________________________________ □ Yes □ No □ Yes □ No □ Yes □ No □ Food premises inspections/audits (JSA # tba) □ Handling/capture of animals (JSA # tba) □ Communicable disease inspections (JSA # tba) □ Block inspections (JSA # tba) □ Domestic premises -squalor/pests (JSA # tba) □ Abandoned vehicles (JSA # tba) □ Swimming pool inspections (JSA # tba) □ Site visitations - Community Safety (JSA # tba) □ Syringe collection (JSA # tba) □ Parking enforcement (JSA # tba) □ Plumbing/wastewater works inspections (JSA # tba) □ Other (task with no JSA/SWMS tba) …………………….. …………………………………………………………….……..(Complete section 2 Assessment then report this to supervisor) Does the JSA/SWMS cover all the hazards and steps in the job? Is the full scope of work and steps understood? Do chemicals on site have SDS’s? Has everyone recently read / signed SWMS / JSAs & SOPs? Are you working alone in a remote or isolated area? Are there contractors on site? Will existing/changing weather conditions impact on the work and/or hazards identified (eg Rain, High Winds, Hot Weather)? Is appropriate PPE available and being utilised? □ Yes □ Yes □ Yes □ Yes □ Yes □ Yes □ No (Complete Section 2 Assessment) □ No (Clarify with supervisor) □ No (Obtain through supervisor) □ No (To be done before work starts) □ No (See WHS 22.1 Staff Safety Calls) □ No (See Contractors Forms) □ Yes □ Yes □ No (specify conditions & controls) □ No (Obtain through supervisor) ………………………………………………………………………….……………………………………………………………………… Is there anything else to consider? (specify) ……………………………………………………………………………………… Section 2 Assessment for extra hazards not identified in the generic JSA /SWMS, and for jobs with no SWMS/JSA Step of Task Hazards Controls Level of Risk ……………………………….. ……………………………….. ……………………………………….……….. …….……….. ………………………………… ………………………………. ……………………………………………….. ……………... ……………………………….. ……………………………….. ……………………………………….……….. …….……….. ……………………………….. ……………………………….. ……………………………………….……….. …….……….. ………………………………. ………………………………. ………………………………………………… ……………… (document details) Pre-Start Meeting attendees - By signing below, I am confirming that I have attended the Pre-start meeting and am fit for duty and not adversely affected by fatigue, drugs or alcohol. I am clear about what is required of me in carrying out this task and am adequately trained to do so. Name of attendee Signature Leading Officer: Attendee: Attendee: Attendee: Section 4 – Sign off on completed checklist As the officer whose name appears at the top of this checklist, I am responsible for filling out this checklist in it’s entirety and I have ensured that all relevant items above are completed and I have followed all relevant procedures in undertaking these tasks: Signature …………………………………………….………………….. Date ………………………………………….. Notes: Completed Job Pre-Start Safety Checklist to be placed in Manager’s tray upon return to the office at the end of the work day SWMS/JSAs to be updated with additional Steps of Job, Hazards, Risks,& Controls when they are frequently reoccurring Job Pre-Start Safety Checklist & other completed forms to be registered to the relevant file in Synergy (12.16.085) The electronic version on Connect in the WHS area is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 1 of 2 (Council Details) Version No: Job Safety Checklist Issued: Next Review: Hazard Identification Code A1 A2 A3 A4 A5 A. Personal Injury/Illness or Death – Due to… Access or egress from site / work area Asbestos / lead Biological (Exposure to infection / infectious diseases) Burns (Exposure or contact with radiant heat, fire, hot objects, sparks) Chemical exposure (use and handling, spill or leak) A19 A20 A21 A22 A23 A6 A7 Confined Spaces Demolition work or alteration of a structure A24 A25 A8 A9 A10 A11 Drowning Dust / Particles / airborne contaminants Electrocution/electric shock Ergonomics (eg workstation, equipment controls) A26 A27 A28 A29 A12 A13 A14 A15 A16 A17 Falling from the same level (eg falling over on the same level) Falling from height (eg falling from one level to another) Falling objects (eg from same level or above) Insect / animal bites and/or stings laceration from sharp or rough edges / objects / materials Manual handling (lifting, bending, twisting, repetitive, cramped, awkward, heavy) A30 A31 B32 A33 A34 Noise (eg machinery) Overhead hazards (power lines, scaffold, equipment, works) Poor lighting Pressurized gas, fuel or refrigerant lines Plant and equipment (entanglement, crush, cut, stab, puncture, shear, burn, strike, struck by moving machinery / mobile plant) Remote or isolated work locations Suffocation by gas, fumes, lack of oxygen (exposure to toxic chemical vapours, exposure to toxic combustion products, exposure to toxic chemical reaction gases) Slipping (eg on loose or wet or slippery surface Traffic / Pedestrians (WZTM) Tripping (eg over an object) Trenching / Excavations (Section C for specific hazard identification) Uneven surface (eg gradient / embankments) Vibration (eg machinery) Working over a pit / hole Weather conditions (wind, rain, UV Radiation, visibility) Other hazards identified - specify Risk Assessment Matrix Likelihood A Almost certain Is expected to occur B Likely Will probably occur “has happened” C Possible Might Occur “Ive heard of it happening” D Unlikely Could occur “Not likely” E Rare May Occur “Practically impossible” Risk Rating E - Extreme risk: H - High risks: M - Moderate risk: L - Low risk: 1 Insignificant No injuries, insignificant damage, minimal financial loss, no impact on staff , no impact on service delivery 2 Minor Minor injury, first aid treatment or minor medical treatment by GP, AE or Out Patient, internal defusing or minimal external debriefing H H M H L M Consequences 3 Moderate Moderate injury, medical treatment required by AE, In Patient and/or specialist, external debriefing, moderate property / equipment damage, moderate financial loss, incident contained with outside assistance 5 Catastrophic Death/s, incident with detrimental effect, service delivery stopped or closed permanently, large financial loss, possible abolition of the service E 4 Major Extensive injuries which may result in death, loss of production capability, incident contained with outside assistance, major financial loss, service delivery reduced or suspended E H E E H E E E L L M H E L L M H H Activity not to commence. Review of task and controls by relevant Works Supervisor, CWMS Coordinator, Recreational Services Coordinator with workgroup to identify control measures to reduce the level of risk. If the risk remans Extreme then authorisation from the General Manager is required before the activity can commence. Authorised by relevant Works Supervisor, CWMS Coordinator, Recreational Services Coordinator. Should only be an acceptable level of risk for ‘Major’ or ‘Catastrophic’ consequences. Authorised by Team Leader. An acceptable level of risk. Manage by routine procedures. An acceptable level of risk Hazard Controls Selecting control measures (WHS Regulations 2012, Regulation 36 – Hierarchy of control measures) 1. 2. Eliminate the risks so far as is reasonable practicable If this is not reasonably practicable, minimise them so far as reasonably practicable by applying the following hierarchy of control measures: Minimise the risk by doing one or more of the following: o substituting the hazard o isolating the hazard o implementing engineering controls If the risk still remains, minimise the remaining risk by implementing administrative controls If the risk still remains, minimise the remaining risk by ensuring the provision and use of suitable personal protective equipment (PPE). (document details) The electronic version on Connect in the WHS area is the controlled version. Printed copies are considered uncontrolled. Before using a printed copy, verify that it is the current version. Page 2 of 2