SUPERVISOR`S RESPONSIBILITIES

advertisement

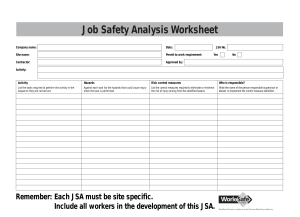

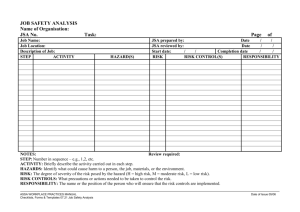

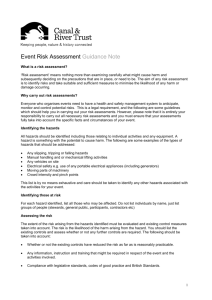

SUPERVISOR RESPONSIBILITIES Who’s Accountable For Employee Safety And Health? THE SUPERVISOR! RESPONSIBILITIES Comply with college’s safety and health program Keep up-to-date with safety and health policies and procedures Oversee workplace training and program implementation RESPONSIBILITIES Establish acceptable levels of risk Do not allow those risk levels to be exceeded Prepare, submit, and store required documentation of safety and health activities RESPONSIBILITIES Provide resources and leadership to keep supervised staff current Conduct job safety analyses on a regular and continuing basis Plan and implement hazard abatement strategies RESPONSIBILITIES Determine an appropriate level of discipline for violation of established safety and health practices and processes Support the college’s team culture concept TRAINING REQUIREMENTS Training time and content based on seriousness of hazards Every employee must participate at least quarterly Training may be tapes, literature, slides, classroom, or brochures Training must be documented JOB SAFETY ANALYSIS Step 1 Break each job into sequence of parts Describe, in order, events required to successfully complete each job Number the activities of each job JOB SAFETY ANALYSIS Step 2 Identify existing and potential hazards List all actual and potential hazards Be sure to include “near misses” Letter each hazard as it corresponds to an activity JOB SAFETY ANALYSIS Step 3 Determine neutralizing or abatement processes for each hazard Identify methods or processes for each real or potential hazard Number each solution CORRECTING HAZARDS Engineer the hazard out if possible Encourage safe work practices Make good administrative decisions Install protective barriers Use proper signage JSA PRIORITIES High accident or injury frequency Greatest potential for serious injury or illness Give attention to jobs with potential injuries that would be the highest cost New jobs - JSA will help identify hazards early PROBLEM AREAS Rushing through the process and not completing parts Identifying hazards, but not adequately addressing them Listing of unclear or non-specific corrective activities BARRIERS Procrastination It has never happened before, so one more time won’t hurt We don’t have time for safety training This safety stuff is no big deal FRINGE BENEFITS Reduces accidents and injuries Increases efficiency by decreasing costs Identifies better ways to do jobs Helps to identify needed PPE Identifies needed training areas Promotes a safety culture, camaraderie and improved morale