NZQA unit standard 16306 version 4

advertisement

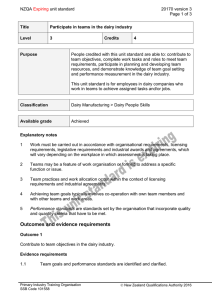

NZQA Expiring unit standard 16306 version 4 Page 1 of 3 Title Identify accident and incident control procedures in the dairy industry Level 4 Credits 6 Purpose People credited with this unit standard are able to identify the principles of accident and incident investigation in the dairy industry, and identify control procedures. Classification Dairy Manufacturing > Dairy Workplace Health and Safety Available grade Achieved Entry information Critical health and safety prerequisites Open. Explanatory notes 1 Organisational requirements refers to instructions to staff on policy and procedures which are documented in memo or manual format and are available in the workplace. These requirements include but are not limited to – site specific requirements, company quality management requirements, and legislative requirements. 2 Legislative requirements in this unit standard include but are not limited to compliance with the Health and Safety in Employment Act 1992, the Health and Safety in Employment Regulations 1995, and subsequent amendments. Outcomes and evidence requirements Outcome 1 Identify the principles of accident and incident investigation in the dairy industry. Evidence requirements 1.1 Elements of accidents and injury prevention are identified in terms of type and effect. Range unsafe acts and conditions; hazard/harm potential; incorrect posture, tools, work methods, environment (e.g. light, air temperature); effects of age; gender; training; skill; knowledge; work patterns; lack of care due to inattention; drugs; alcohol; Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 16306 version 4 Page 2 of 3 tiredness; family health; stress; changes to work methods; work patterns; deadlines; conditions of employment, work standards and practices. 1.2 Work practices and areas are analysed and the causes of accidents are identified in terms of type and effect. Range 1.3 root causes; training and skill requirements; trends; hazard exposure; monotonous/repetitive task; occupational overuse syndrome; concerns of people; unmanageable work loads; alternative methods; suitability of personal protective equipment; other equipment and tools. Accident investigation procedures are identified according to site requirements. Range hazard control, prevention, protection, hazard operability study (HAZOP), hazard analysis (HAZAN) audits, failure mechanisms, unsafe practices, recognition and identification of hazardous substances, accident causation and prevention. 1.4 Procedures for accident prevention and reporting are identified and explained according to statutory requirements. 1.5 Job safety analysis procedures are identified according to site procedures. 1.6 Safety policies and objectives, and management and supervisor responsibilities are identified according to company policy. Range 1.7 case histories and studies relating to accidents and failures, knowledge, skills, competence, performance, attitude required, work sequence breakdown and procedures, analysis of job, equipment and personnel involved. Barriers to accident investigation are identified to ensure validity and accuracy. Range organisational culture, blame versus learning, personnel support. Outcome 2 Identify control procedures. Evidence requirements 2.1 Control methods of work areas and practices are identified. Range identification and severity rating, risk assessment, rest periods, job focus, alternative duties, micropause and relaxation techniques, alternative methods. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 2.2 The planning process is identified according to site requirements. Range 2.3 workflow control, task organisation, manage work patterns and changes, environment, communication and housekeeping, assign, review responsibilities, duties and goals. Site safety documents are located and applications identified. Range 2.4 16306 version 4 Page 3 of 3 material safety data sheets, site specific operations and maintenance procedures, safety procedures. Preventative actions and procedures are identified relative to site procedures. Range training to reduce accident potential; back up systems in place and operative; maintenance systems operating; housekeeping; safety training programmes; follow up eg reports, inspections, training, discussions, questions. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 5 July 1999 31 December 2017 Revision 2 13 June 2003 31 December 2017 Rollover 3 26 January 2007 31 December 2017 Review 4 15 October 2015 31 December 2017 Consent and Moderation Requirements (CMR) reference 0022 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016