Increased availability thanks to new

frequency converters at Reuter West CHP

Reference – Electrical Solutions

Instrumentation, Controls & Electrical

SPPA-E3000 Drive Modernization

involved the replacement of the frequency

converters for the mill air fans at the Reuter

West combined heat and power plant. This led

to a significant increase in plant availability.

The Result

■ Increased availability

thanks to modernized

frequency converter

■ Lower auxiliary power

consumption due to

optimized closed-loop

control and recovery

■ Improved maintenance as a

result of stocking of spare

parts and timely servicing

■ Reduced capital investment

thanks to continued usage

of various principal

components (motor,

transformer, etc.)

■ Quick return on investment

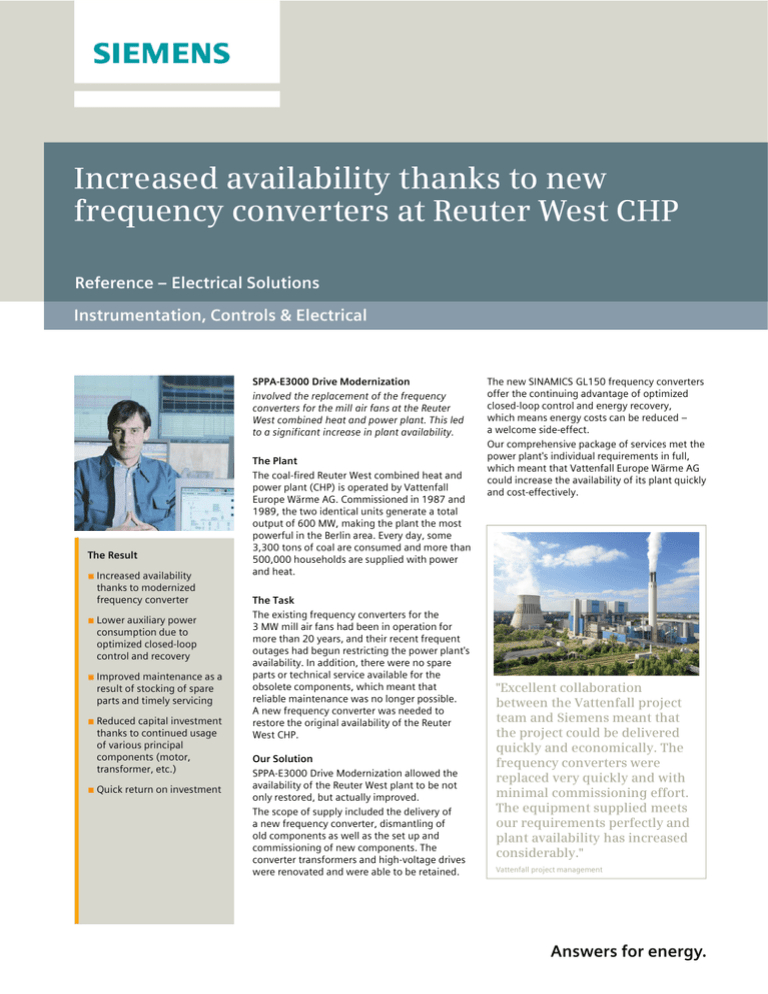

The Plant

The coal-fired Reuter West combined heat and

power plant (CHP) is operated by Vattenfall

Europe Wärme AG. Commissioned in 1987 and

1989, the two identical units generate a total

output of 600 MW, making the plant the most

powerful in the Berlin area. Every day, some

3,300 tons of coal are consumed and more than

500,000 households are supplied with power

and heat.

The Task

The existing frequency converters for the

3 MW mill air fans had been in operation for

more than 20 years, and their recent frequent

outages had begun restricting the power plant's

availability. In addition, there were no spare

parts or technical service available for the

obsolete components, which meant that

reliable maintenance was no longer possible.

A new frequency converter was needed to

restore the original availability of the Reuter

West CHP.

Our Solution

SPPA-E3000 Drive Modernization allowed the

availability of the Reuter West plant to be not

only restored, but actually improved.

The scope of supply included the delivery of

a new frequency converter, dismantling of

old components as well as the set up and

commissioning of new components. The

converter transformers and high-voltage drives

were renovated and were able to be retained.

The new SINAMICS GL150 frequency converters

offer the continuing advantage of optimized

closed-loop control and energy recovery,

which means energy costs can be reduced –

a welcome side-effect.

Our comprehensive package of services met the

power plant's individual requirements in full,

which meant that Vattenfall Europe Wärme AG

could increase the availability of its plant quickly

and cost-effectively.

"Excellent collaboration

between the Vattenfall project

team and Siemens meant that

the project could be delivered

quickly and economically. The

frequency converters were

replaced very quickly and with

minimal commissioning effort.

The equipment supplied meets

our requirements perfectly and

plant availability has increased

considerably."

Vattenfall project management

Answers for energy.

Published by and copyright © 2013:

Siemens AG, Energy Sector

Freyeslebenstrasse 1

91058 Erlangen

For more information contact

sppa-e3000.energy@siemens.com

www.siemens.com/energy/sppa-e3000

Siemens Energy, Inc.

Instrumentation, Controls, & Electrical

1345 Ridgeland Parkway, Suite 116

Alpharetta, GA 30004, USA

E306_FR_Reuter-West-DrMod_e_V1-0

Order no.: E50001-G230-A339-X-4A00

Printed in Germany

Dispo 05401, c4bs-Nr. 7465

Printed on elementary chlorine-free

bleached paper.

Unrestricted

AL:N ECCN:N

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.