State-of-the-art control systems

at Tusimice II for high efficiency –

now and in the future

Reference – Control System

Instrumentation, Controls & Electrical

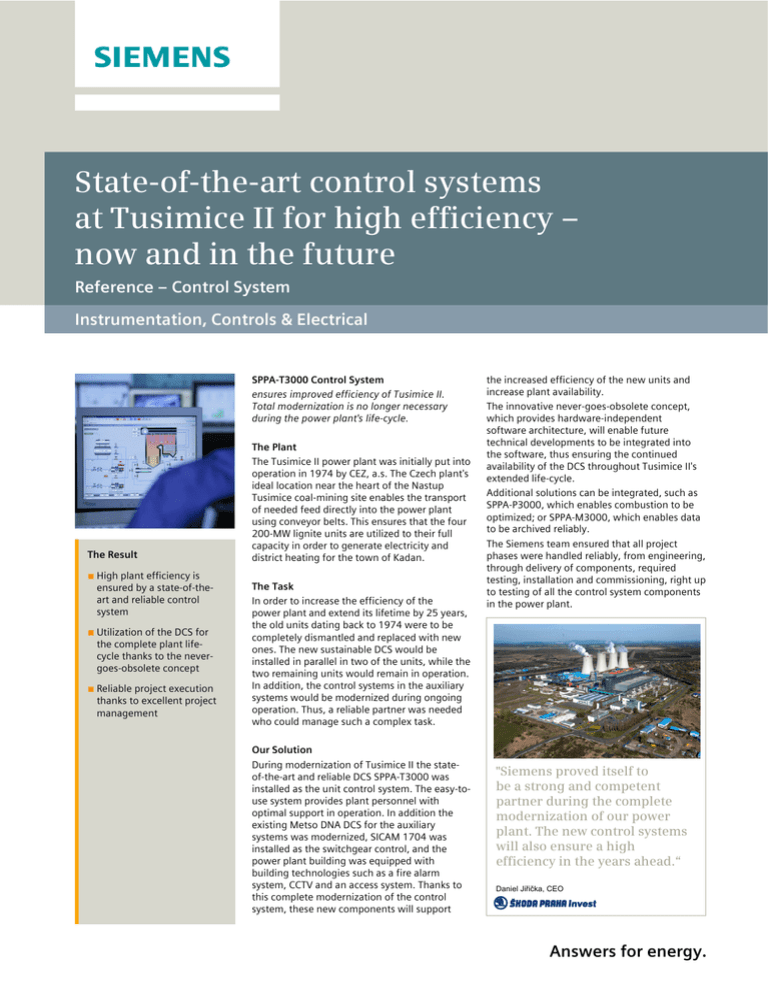

SPPA-T3000 Control System

ensures improved efficiency of Tusimice II.

Total modernization is no longer necessary

during the power plant's life-cycle.

The Result

■ High plant efficiency is

ensured by a state-of-theart and reliable control

system

■ Utilization of the DCS for

the complete plant lifecycle thanks to the nevergoes-obsolete concept

■ Reliable project execution

thanks to excellent project

management

The Plant

The Tusimice II power plant was initially put into

operation in 1974 by CEZ, a.s. The Czech plant's

ideal location near the heart of the Nastup

Tusimice coal-mining site enables the transport

of needed feed directly into the power plant

using conveyor belts. This ensures that the four

200-MW lignite units are utilized to their full

capacity in order to generate electricity and

district heating for the town of Kadan.

The Task

In order to increase the efficiency of the

power plant and extend its lifetime by 25 years,

the old units dating back to 1974 were to be

completely dismantled and replaced with new

ones. The new sustainable DCS would be

installed in parallel in two of the units, while the

two remaining units would remain in operation.

In addition, the control systems in the auxiliary

systems would be modernized during ongoing

operation. Thus, a reliable partner was needed

who could manage such a complex task.

Our Solution

During modernization of Tusimice II the stateof-the-art and reliable DCS SPPA-T3000 was

installed as the unit control system. The easy-touse system provides plant personnel with

optimal support in operation. In addition the

existing Metso DNA DCS for the auxiliary

systems was modernized, SICAM 1704 was

installed as the switchgear control, and the

power plant building was equipped with

building technologies such as a fire alarm

system, CCTV and an access system. Thanks to

this complete modernization of the control

system, these new components will support

the increased efficiency of the new units and

increase plant availability.

The innovative never-goes-obsolete concept,

which provides hardware-independent

software architecture, will enable future

technical developments to be integrated into

the software, thus ensuring the continued

availability of the DCS throughout Tusimice II's

extended life-cycle.

Additional solutions can be integrated, such as

SPPA-P3000, which enables combustion to be

optimized; or SPPA-M3000, which enables data

to be archived reliably.

The Siemens team ensured that all project

phases were handled reliably, from engineering,

through delivery of components, required

testing, installation and commissioning, right up

to testing of all the control system components

in the power plant.

"Siemens proved itself to

be a strong and competent

partner during the complete

modernization of our power

plant. The new control systems

will also ensure a high

efficiency in the years ahead.“

Daniel Jiřička, CEO

Answers for energy.

Published by and copyright © 2013:

Siemens AG, Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

For more information contact

sppa-t3000.energy@siemens.com

www.siemens.com/energy/sppa-t3000

Siemens Energy, Inc.

Instrumentation, Controls, & Electrical

1345 Ridgeland Parkway, Suite 116

Alpharetta, GA 30004, USA

T3_FR_Tusimice_e_V1-0

Order no. E50001-G230-A342-X-4A00

Printed in Germany

Dispo 05401, c4bs-Nr. 7465

Printed on elementary chlorine-free

bleached paper.

Unrestricted

AL:N ECCN:N

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.