BB44 FA/PA HP/IP Turbine

Modernization

Scope of supply

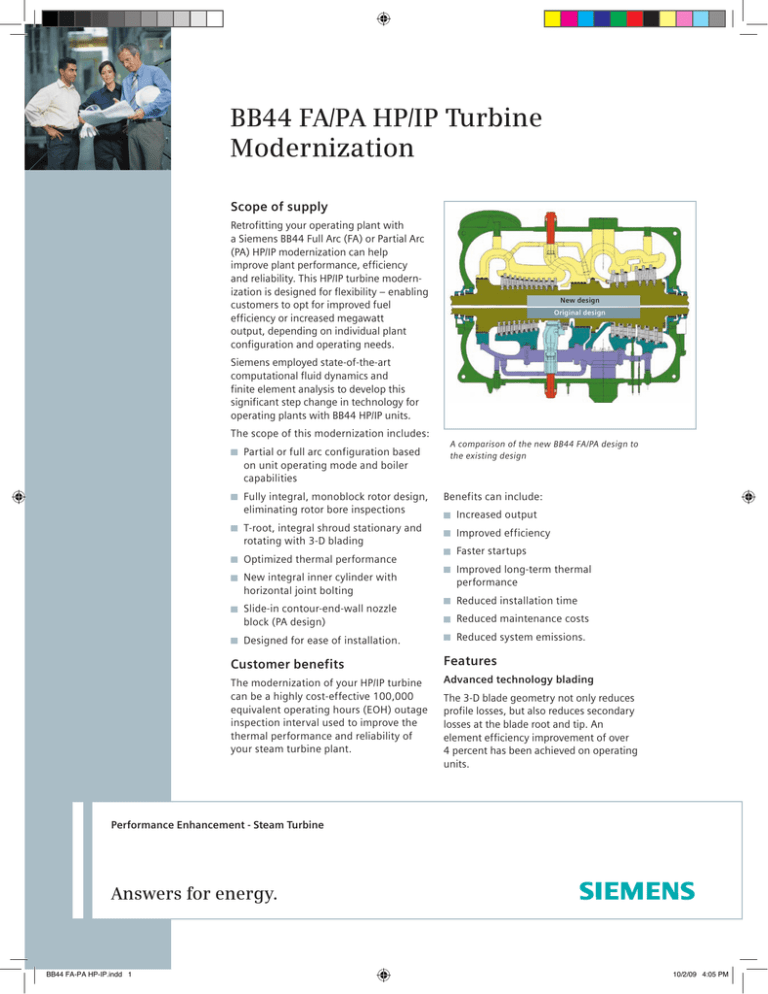

Retrofitting your operating plant with

a Siemens BB44 Full Arc (FA) or Partial Arc

(PA) HP/IP modernization can help

improve plant performance, efficiency

and reliability. This HP/IP turbine modernization is designed for flexibility – enabling

customers to opt for improved fuel

efficiency or increased megawatt

output, depending on individual plant

configuration and operating needs.

New design

Original design

Siemens employed state-of-the-art

computational fluid dynamics and

finite element analysis to develop this

significant step change in technology for

operating plants with BB44 HP/IP units.

The scope of this modernization includes:

Partial or full arc configuration based

on unit operating mode and boiler

capabilities

Fully integral, monoblock rotor design,

eliminating rotor bore inspections

T-root, integral shroud stationary and

rotating with 3-D blading

Optimized thermal performance

New integral inner cylinder with

horizontal joint bolting

Slide-in contour-end-wall nozzle

block (PA design)

Designed for ease of installation.

A comparison of the new BB44 FA/PA design to

the existing design

Benefits can include:

Increased output

Improved efficiency

Faster startups

Improved long-term thermal

performance

Reduced installation time

Reduced maintenance costs

Reduced system emissions.

Customer benefits

Features

The modernization of your HP/IP turbine

can be a highly cost-effective 100,000

equivalent operating hours (EOH) outage

inspection interval used to improve the

thermal performance and reliability of

your steam turbine plant.

Advanced technology blading

The 3-D blade geometry not only reduces

profile losses, but also reduces secondary

losses at the blade root and tip. An

element efficiency improvement of over

4 percent has been achieved on operating

units.

Performance Enhancement - Steam Turbine

Answers for energy.

BB44 FA-PA HP-IP.indd 1

10/2/09 4:05 PM

Stiffening rib

Siemens 3-DS Blading

Inner cylinder with rib-cover half

Integral inner cylinder

Experience

One feature of this configuration is a

stiffening rib, providing a robust design

that minimizes distortion. The integration

of the inner cylinder/blade rings/dummy

rings, through use of a single casting,

eliminates leakage paths associated

with tongue-and-groove fits. In addition,

this configuration can help decrease the

duration of future maintenance outages

due to advanced technology and the

reduced number of components.

Outage installation times of as little

as four weeks can help minimize your

payback time and maximize your

profitability.

Inlet flow configuration

The BB44 FA/PA inlet guides the

flow directly into the HP blade path,

eliminating the turnaround and reducing

associated turning losses.

The 44FA/PA designs have been successfully installed and are in operation.

For more information, please contact

your local Siemens representative.

Partial arc configuration includes

upgraded control stage blading, nozzle

block and nozzle chamber

Full arc configuration eliminates

the control stage blading, nozzle

block and nozzle chamber for

maximum efficiency for units that

operate primarily at full load.

Published by and copyright © 2009:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

For more information, contact our

Customer Support Center.

Phone: +49 180/524 70 00

Fax:

+49 180/524 24 71

(Charges depending on provider)

E-mail: support.energy@siemens.com

Energy Service Division

Order No. E50001-D520-A251-X-76US

Printed in USA

BU 2009912123942255F IN 1009.2

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore

be specified in the contract.

www.siemens.com/energy

BB44 FA-PA HP-IP.indd 2

10/2/09 4:05 PM