Patnow II– maximum availability

from minimum fuel input

Control Systems Reference

Instrumentation, Controls & Electrical

SPPA-T3000 Control System

allows the Patnow II power plant to operate

fully automatically – an I&C system which

maximizes plant availability and optimizes

the use of fuels.

The Result

■ Maximum plant availability

thanks to automated

procedures and integration

of all technological components

■ Increased economic

efficiency thanks to the

optimized use of fuel and

extended durability

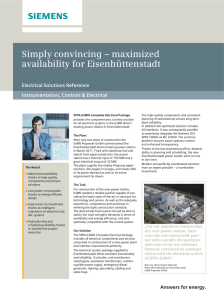

The Plant

Constructed in 2008, the Patnow II steam

power plant is the most recent of the four

power plants operated by ZE PAK SA.

Patnow II comprises one unit with an output

of 474 MW. Located in Konin, 100 km to the

east of Poznan, it supplies the region’s end

users with electricity.

ZE PAK SA provides a total of 8.5 % of Poland’s

energy requirements and is thus the second

largest producer of electricity from lignite in

the country.

The Task

When the plant was constructed, it was

important to create an overall concept which

would allow the unit to be operated fully automatically, including the associated ancillary

facilities and flue gas cleaning plant, but also to

incorporate external systems manufactured by

other suppliers. Moreover the control system

should enable the plant to be operated economically with a long durability and guarantee

maximum availability for all load scenarios.

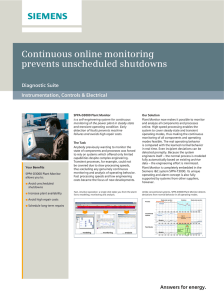

Our Solution

SPPA-T3000 ensures a high level of automation

which increases plant availability and economic

efficiency.

By implementing this I&C system all operations

of the unit including associated auxiliary and

auxiliary system were fully automated.

Additionally the existing systems and technological components manufactured by other

suppliers were incorporated. This modern

I&C system monitors the use of fuel, assesses

the necessary input and optimizes its usage.

Thereby the economic efficiency of the plant is

increased.

The automated start-up and shutdown

processes likewise fulfill the specified load

operation requirements according to the

statutory regulations which apply in Poland.

Also the power plant’s durability is increased

by remaining within the load limits for cold and

warm starts and during load cycling.

The operator control and monitoring system for

decentralized process control and archiving is

easy to use. It also enables power plant staff to

quickly filter out data which is relevant to them

and to make changes to processes without any

errors.

“When building our latest

power plant, Patnow II, we

wanted to make sure that the

unit would operate on a fully

automatic basis by using

state-of-the-art technology.

Thanks to the SPPA-T3000

control system, we now have

a power plant that offers

maximum availability from a

minimized resource input.”

A. Grudzien, Power Plant Manager Patnow II

Answers for energy.

Published by and copyright © 2012:

Siemens AG, Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

For more information contact

sppa-t3000.energy@siemens.com

www.siemens.com/energy/sppa-t3000

Siemens Energy, Inc.

Instrumentation, Controls, & Electrical

1345 Ridgeland Parkway, Suite 116

Alpharetta, GA 30004, USA

T3_FR_Patnow-Poland_e_V2-0

Order no. E50001-G230-A306-X-4A00

Printed in Germany

Dispo 05401, c4bs-Nr. 7465

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore

be specified in the contract.