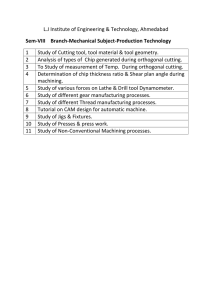

Class time - B Tech Mechanical Engineering

advertisement

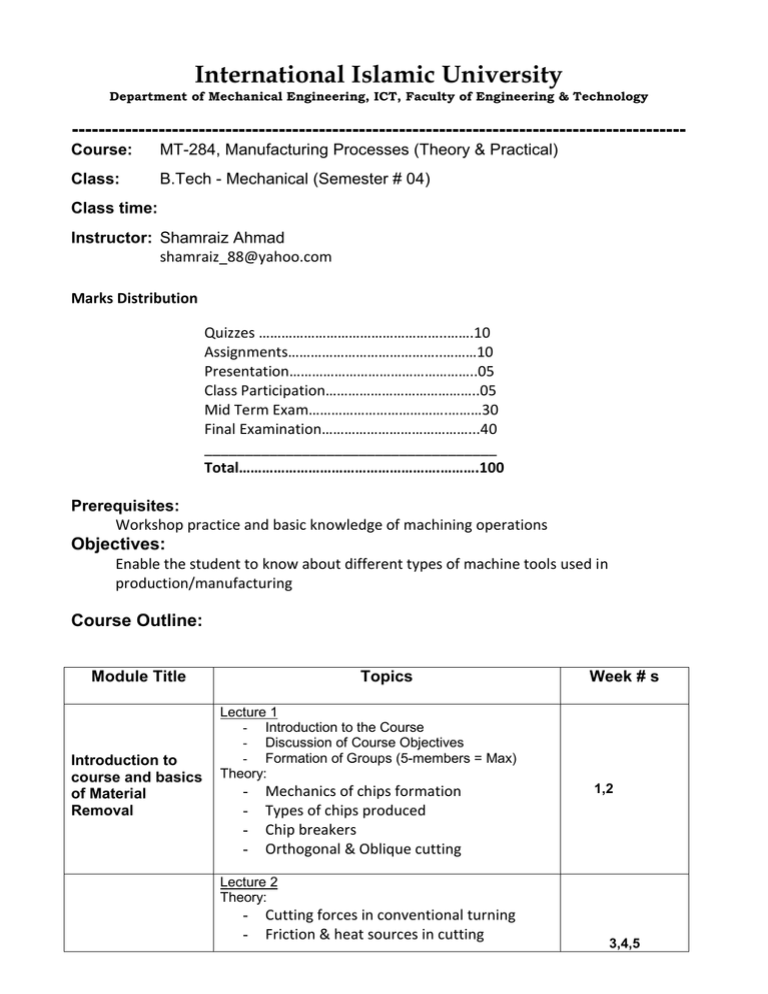

International Islamic University Department of Mechanical Engineering, ICT, Faculty of Engineering & Technology -------------------------------------------------------------------------------------------Course: MT-284, Manufacturing Processes (Theory & Practical) Class: B.Tech - Mechanical (Semester # 04) Class time: Instructor: Shamraiz Ahmad shamraiz_88@yahoo.com Marks Distribution Quizzes …………………………………………..…….10 Assignments…………………………………..………10 Presentation…………………………………………..05 Class Participation…………………………………..05 Mid Term Exam……………………………….………30 Final Examination…………………………………...40 ____________________________________ Total…………………………………………….……….100 Prerequisites: Workshop practice and basic knowledge of machining operations Objectives: Enable the student to know about different types of machine tools used in production/manufacturing Course Outline: Module Title Introduction to course and basics of Material Removal Topics Week # s Lecture 1 - Introduction to the Course - Discussion of Course Objectives - Formation of Groups (5-members = Max) Theory: - Mechanics of chips formation Types of chips produced Chip breakers Orthogonal & Oblique cutting 1,2 Lecture 2 Theory: - Cutting forces in conventional turning Friction & heat sources in cutting 3,4,5 Material Removal - Surface finishing processes, Lapping, Honing, Super finishing, Polishing, Buffing, Electroplating, Galvanizing, Metal Spraying. Practical: - Study of Broaching machine Lecture 3 Theory: Cutting Tools - Single point tool Geometry Multi point tools Tool life & wear, Tool failure, Factors affecting tool life, Measuring tool life Tool material & its characteristics Cutting fluids, Purposes, Types & properties of cutting fluids. 6,7,8 Practical: - Study of Press machine Lecture 4 Theory: Machining Processes - Broaching & broaching machines Press machine, Types of Press machines, Press work operations 9,10 Practical: - Practice on press machines to make different shapes 11 MID-TERM EXAMS Lecture 5 Theory: Sheet Metal Forming Sheet metal characteristics, Formability of sheet metals, Bending sheet & plate, Tube bending & forming, Deep drawing, Super plastic forming 12,13 Practical: - Study of bending machine Lecture 6 Theory: Jigs & Fixtures General Design principle, Elements of Jig, Locating Devices & Clamping Devices. Practical: - Bending Sheet metals of 14,15 different thickness Lecture 7 Theory: Non-Conventional Machining Processes - Ultrasonic machining Abrasive-jet machining Water-jet machining Electrical discharge machining (EDM) 16,17 - Electromechanical machining & grinding, Practical: - Practice on making of simple jigs and clamping & locating devices. Lecture 8 Theory: Non-Conventional Machining Processes - Laser beam machining Electron beam machining Chemical milling Chemical Blanking Chemical Engraving. 18,19 Practical: - Mini Project on making a simple Jig or Fixture. FINAL EXAM Books Recommended: 1. Elements of Workshop Technology Vol. II by SK Hajra Choudry. 2. Manufacturing Processes BH Amstead & PF Ostwald 20