A comparative study of the cutting forces in high speed machining

advertisement

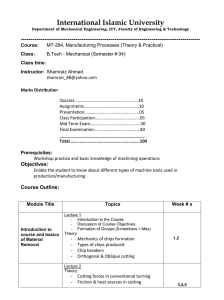

N. Fang, Q. Wua Andrew Orme 5 October 2009 • Ti-6Al-4V • Inconel 718 • Same set-up • Measure cutting forces • Tool wear • Machined surface integrity (aerospace) • Tool life • Economics Arunachalam, R., Mannan, M.A., 2000. Machinability of nickelbased high temperature alloys. Mach. Sci. Technol. 4, 127–268. Albrecht, P., 1960. New developments in the theory of metal cutting process: part I—the ploughing process in metal cutting. ASME J. Eng. Indus. 82, 348–357. Baker, M., Rosler, J., Siemers, C., 2002. Finite element simulation of segmented chip formation of Ti6Al4V. ASME J. Manufact. Sci. Eng. 124, 485–488. Barry, J., Byrne, G., Lennon, D., 2001. Observations on chip formation and acoustic emission in machining Ti–6Al–4V alloy. Int. J.Mach. Tools Manuf. 41, 1055–1070. Bayoumi, A.E., Xie, J.Q., 1995. Some metallurgical aspects of chip formation in cutting Ti–6wt %Al–4wt. %V alloy. Mater. Sci. Eng. A 190, 173–180. Behrens, A., Kalisch, K., Wulfsberg, J.P., 2004. Possibilities and problems of finite element simulation of high speed cutting mechanics. In: Proceedings of the 2004 ASME International Mechanical Engineering Congress and R&D Exposition, Anaheim, CA, pp. 1–9. Coelho, R.T., Silva, L.R., Braghini, A., Bezerra, A.A., 2004. Some effects of cutting edge preparation and geometric modifications when turning INCONEL 718 (TM) at high cutting speeds. J. Mater. Process. Technol. 148, 147–153. Dudzinski, D., Devillez, A., 2004. A review of developments towards dry and high speed machining of Inconel 718 alloy. Int. J. Mach. Tools Manuf. 44, 439–456. Ezugwu, E.O., Bonney, J., 2003.An overviewof the machinability of aeroengine alloys. J. Mater. Process Technol. 134, 233–253. Ezugwu, E.O., Fadare, D.A., Bonney, J., Silva, R.B., Sales, W.F., 2005. Modeling the correlation between cutting and process parameters in highspeed machining of Inconel 718 alloy using an artificial neural network. Int. J. Mach. Tools Manuf. 45, 1375–1385. Fang, N., 2003. Slip-line modeling of machining with a roundededge tool, part I: new model and theory. J. Mech. Phys. Solids 51, 715–742. Fang, N., Wu, Q., 2005. The effects of chamfered and honed tool edge geometry in machining of three aluminum alloys. Int. J. Mach. Tools Manuf. 45, 1178–1187. Komanduri, R., Hou, Z.B., 2002. On thermoplastic shear instability in the machining of a titanium alloy (Ti–6Al–4V). Metall. Mater. Trans. A 33A, 2995–3010. Nabhani, F., 2001. Machining of aerospace titanium alloys. Roboti. Comput. Integr. Manuf. 17, 99–106. Nalbant, M., Altm, A., Gokkaya, H., 2007. The effect of cutting speed and cutting tool geometry on machinability properties of nickel-base Inconel 718 super alloys. Mater. Des. 28, 1334–1338. Narutaki, N., Yamane, Y., 1993. High speed machining of Inconel 718 with ceramic tools. Annals of CIRP 42, 103–106. Quan, Y.M.,Wang, C.Y., He, Z.W., 2004. Experimental investigation on the high speed machining of hardened steel. Adv. Mater. Manufact. Sci. Technol. Mater. Sci. Forum 471–472, 339–343. Roth, R.N., Oxley, P.L.B., 1972. Slip-line field analysis for orthogonal machining based upon experimental flow field. J. Mech. Eng. Sci. 14, 85–97. Schulz, H., Abele, E., Sahm, A., 2001. Material aspects of chip formation in HSC machining. CIRP Annal. 50, 45–48. Shirakashi, T., Obikawa, T., 1998. Recent progress and some difficulties in computational modeling of machining. Mach. Sci. Technol. 2, 277– 301. Siems, S., Dollmeier, R., Warnecke, G., 2000. Material behavior of aluminum alloy 7075 and AISI 1045 steel in high speed machining. Trans. NAMRI/SME 28, 101–106. Su, Y., He, N., Li, L., Li, X.L., 2006. An experimental investigation of effects of cooling/lubrication conditions on tool wear in high-speed endmilling of Ti–6Al–4V. Wear 261, 760–766. Usui, E., Hoshi, K., 1963. Slip-line fields in metal machining which involve centered fans. In: Proceedings of the International Production Engineering Research Conference, ASME, Pittsburgh, pp. 61–71. Wu, Q., Fang, N., 2006. Effect and modeling of tool edge wear in high-speed finish machining of supperalloy Inconel 718. Trans. NAMRI/SME 34, 340–397 Liu, K., Li, X.P., Rahman,M., Neo, K.S., Liu, X.D., 2007. A study of the effect of tool cutting edge radius on ductile cutting of siliconwafers. Inter. J. Adv.Manuf. Technol. 32, 631–637. Molinari, A., Musquar, C., Sutter, G., 2002. Adiabatic shear banding in high speed machining of Ti–6Al–4V: experiments and modeling. Int. J. Plast. 18, 443–459. • Normal, Thrust, Cutting Force • Equations Fc = Fs cos ( b - a)/[cos ( f + b - a)] Ft = Fs sin ( b - a)/[cos ( f + b - a)] • Good comparison • Minimize variation • High Strength to weight ratio • Low thermal conductivity • Heat •Chip formation • Cutting Forces • Cutting Power • Cutting Energy • Material Removal Rate • Tool geometry •Small feed rates 0.075, 0.09, 0.105, 0.12mm/r • Work material (tube) Ti–6Al–4V and Inconel 718 • Tube outer diameter 50mm • Tube wall thickness 1.4mm for Ti–6Al–4V 1. 2mm for Inconel 718 • Tool insert TPG 432 (Kennametal Inc.) • Tool material Cemented carbide (KC 8050) with TiC/TiN/TiCN coating • Tool working rake angle 5◦ • Tool edge radius 0.06mm (.002in) • Cutting speed 58, 87, 116, 144, 174m/min .05*π=.157m 174m/min * 1rev/.157m = 1107rpm. • CNC Turning Lathe • Finish Machining • Five Cutting Speeds • Four feed rates • No cutting fluid or coolant • Tool radius measured after each cycle • Kistler Dynamometer • Kistler Amplifier • Data Acquisition System(Labview) • 20 Cutting Tests for each material • Most tests repeated 3 times (a) Ti (b) Inconel (a)Ti (b) Inconel Force Ratio • Determines direction of resultant force •Cutting Force Fc_Ti64=103.52Vc−0.155f0.784w Fc_In718=103.81Vc−0.153f0.894w • Thrust Force Ft_Ti64=103.02Vc−0.257f0.127w Ft_In718=103.41Vc−0.216f0.495w • Resultant Force RTi64=103.44Vc−0.202f0.483w RIn718=103.80Vc−0.175f0.746w •Force Ratio Fc_Ti64/Ft_Ti64=100.508Vc0.101f0.657 Fc_In718/Ft_In718=100.394Vc0.0635f0.400 Increased cutting speed means lower cutting forces but higher force ratio. 2. Increased feed rate means increased cutting forces and increased force ratio. 3. Cutting force and thrust are higher for Inconel than for Titanium. 4. As feed rate changes, thrust force varies more in Inconel than Titanium. 1. • Jet Engines • Aerospace • High strength to low weight ratio • High Speed Machining? Develop new tools • Equations can be used to estimate cutting forces.