Introduction, History, Advantages, Disadvantages

advertisement

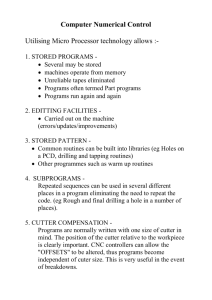

Introduction History, Advantages, Disadvantages, Applications, Elements of Machine Control Introduction to the concept of computer numerical control Definition of Numerical Control (NC): • A versatile form of programmable automation in which machine movements and various other functions are controlled by instructions expressed as a series of letters, numbers and symbols initiated via an electronic control system. History • 1725; England, punched cards were used to control the cloth pattern of knitting machine operation • 1863; automatic player piano, used air passing through holes in a perforated paper drum to control keyboard mechanism in a preprogrammed sequence. • 1952; first NC machine built by MIT Direct Numerical Control: NC machines are operated directly from a remote computer Computerized Numerical Control (CNC): late 60's early 70's: • When the control system utilizes a dedicated internal computer positioned on the machine. A dedicated computer is built into the Machine Control Unit (MCU) of one machine tool. The internal computer allows for the following: • • • • • • Storage of additional programs Program editing Running of programs from memory Machine and control diagnostics Special routines Inch/metric-incremental/absolute switchability 6 Elements of CNC system: • 1. Part program • 2. Program input device • 3. Machine control unit (MCU) – reads and interprets coded instructions for machining the particular work piece, then generates electric output signals • 4. Drive system • 5. machine tool • 6. Feedback system (sometimes) Advantages of CNC: • • • • • • Increases productivity High accuracy and repeatability Reduced production costs Reduced indirect operating costs Complex machining operations Greater flexibility Adv. (Continued) • • • • • Lower operator shill required Facilitates flexible automation Reduced rejection rates Reduced tooling costs Improved production planning and control Limitations of CNC: • 1. High initial investment • 2. High maintenance • 3. Not cost effective for low production levels Applications of CNC: • • • • 1. Chip removal 2. Grinding 3. Unconventional Machining 4. Fabrication Specifically: • Metal, wood, plastic, etc. cutting • Flame cutting, waterjet cutting, laser cutting • Sheet metal forming and punching • Electrical discharge machining (EDM) • Welding Fewer employees will be required but those needed will be technicians with knowledge of metal-cutting methods, cutting speeds and feeds, work holding, and tool set-up Cannot eliminate human involvement totally from the machining process. • There is no automatic control system capable of making a decision in the true sense of the word. Its capability is restricted to responding to a manual or computer prepared program Elements of Machine Control 1. Slide movements • Hydraulically actuated pistons • Electric servo motors (common) • Axis of movement are X, Y, & Z (sometimes referred to as U, V, & W) • Z axis is always related to motion parallel to the spindle axis • Length of travel of slide movement is called “Coordinate Dimension” • Slide movement caused by Servo Parameters of control for slide movements • • • • Starting and stopping Direction Feed rate (how fast) Distance Rotary Movements • A about X • B about Y • C about Z 2. Machine spindles • Electric motors • Hydraulic motors Parameters of control for spindles • Stopping and starting • Direction (CW or CCW) • Speed of rotation 3. Tooling • Turrets • Magazines (chain) • Manual intervention 4. Work holding • Automatic (electric, hydraulic, pneumatic actuated vises, chucks, collets, robots, pallets) • Manual intervention 5. Supporting functions • Apply coolant • Blast of air to clear chips • etc.