Study of Cutting tool, tool material & tool geometry.

advertisement

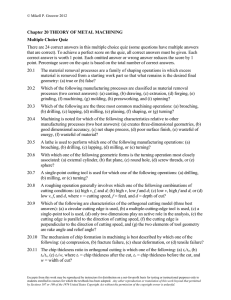

L.J Institute of Engineering & Technology, Ahmedabad Sem-VIII Branch-Mechanical Subject-Production Technology 1 2 3 4 5 6 7 8 9 10 11 Study of Cutting tool, tool material & tool geometry. Analysis of types of Chip generated during orthogonal cutting. To Study of measurement of Temp. During orthogonal cutting. Determination of chip thickness ratio & Shear plan angle during machining. Study of various forces on Lathe & Drill tool Dynamometer. Study of different gear manufacturing processes. Study of different Thread manufacturing processes. Tutorial on CAM design for automatic machine. Study of Jigs & Fixtures. Study of Presses & press work. Study of Non-Conventional Machining processes. Practical-1 AIM - Study of Cutting tool, tool material & tool geometry. 1 2 3 4 5 6 7 Classification of cutting tools. List the cutting tool materials. State the desirable characteristics of cutting tool material Explain different types of tool material. List Tool Nomenclature systems & explain ASA system with fig. Significance of tool geometry on machining. Explain different types of single point cutting tool. Explain multipoint cutting tool. 1. Twist drills 2. Plain Milling cutters 3. Standard broch Give the function of cutting tools Practical-2 Analysis of types of Chip generated during orthogonal cutting. 1 2 Explain mechanism of chip formation with neat sketch. Explain types of chip & discuss the factors which affect the formation of chip in metal cutting. Practical Data. Practical-3 To Study of measurement of Temp.during orthogonal cutting. 1 Explain orthogonal cutting. 2 Explain the significance of temperature and sources of heat generation in metal cutting. Explain in brief method of temperature measurement in metal cutting. Practical data. Practical-4 Determination of chip thickness ratio & Shear plan angle during machining. Practical Practical-6 Study of different gear manufacturing processes. 1 2 3 4 5 List out various Gear manufacturing processes. Explain gear Hobbing process. Explain gear Shaping process. Explain Gear cutting on a Milling machine. Write Short note on Gear finishing process Practical-7 Study of different Thread manufacturing processes. 1 2 3 4 5 List out various Thread manufacturing processes. Discus screw thread chasing procedure on a center lathe. Explain function of thread dial on a center lathe. Explain with sketch Write advantages and limitation of thread rolling process Write the processes for making internal thread & explain them. Explain thread grinding process. Practical-8 Tutorial on CAM design for automatic machine. Practical Practical-9 AIM - Study of Jigs & Fixtures. 1 2 3 4 5 6 Define the terms a jig and a fixture. When they are recommended? What is meant by ‘clearance’ as applied to jigs and fixtures. Differences a jig and a fixture. Explain with sketch the basic principles of Jig/fixtures design Describe with sketch various types of locators stating applications. State design requirements for clamps. Also sketch any two type of quick acting clamp. Explain 3-2-1 principle of location for jigs and fixtures design. Practical-10 AIM - Study of Presses & press work 1 2 3 4 5 What are the various ways in which presses can be classified? What factors should be considered for selecting the appropriate press for the given job? Explain classification of dies. Define the terms used for press working bed, bolster plate, die, die block, die set, punch, lower shoe, upper shoe, punch plate, backup plate, stripper, knock out, pit man, shut height, guide posts. What is meant by “clearance”? Why is it important in shearing operation? Sketch a sectioned view of blanking die, and label on it: clearance, straight and angular clearance. Explain different Press operations. Practical-11 AIM - Study of Non-Conventional Machining processes. 1 2 3 4 5 6 What do you mean by unconventional machining process? Give reason for their development. What is ultrasonic machining method? Explain it with figure. What is the function of horn in it? What is electron beam machining? Explain it with figure. Why vacuum is required for this process? Describe Electro Discharge machining process with figure and also explain working principle and application What is long form of “Laser”? State the advantages of laser beam machining. Explain Electro-Chemical Machining with neat sketch also gives its advantage, disadvantage and application.