2-Uses of Urea - Pharos University in Alexandria

advertisement

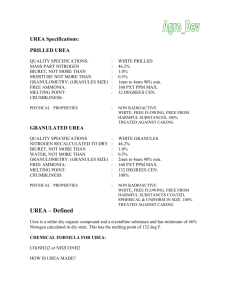

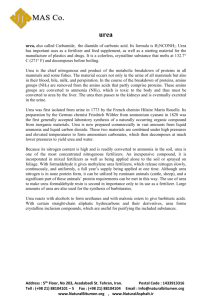

Pharos University Faculty of Engineering Petrochemical Department جامعه فاروس كلية اهلندسة قسم البرتوكيماوايت LECTURE (9) Manufacture of Urea 1-Introduction Urea (carbamide) is a high quality nitrogenous fertilizer with 46% nitrogen content. It is called carbamide because it has two groups of NH2. 2-Uses of Urea Making urea formaldehyde resins from which in turn high quality plastics. Synthetic glues. Compositions for impregnating cloth to improve cloth. Pharmaceutics industry . Manufacturing synthetic fibers 3-Properties of Urea Molecular weight: 60.06 Nitogen content: 46.6% Color: White Specific gravity: 1.335 Melting point: 132.7 C Solubility in water (parts/100 part of water) 0 C: 66.7 40C: 167.0 80 C: 400.0 100 C: 733.0 4-Advantages of Fertilizer Urea: Urea can be applied to soil as a solid or solution or to certain crops as a foliar spray. Urea usage involves little or no fire or explosion hazard. Urea’s high analysis, 46% N, helps reduce handling, storage and transportation costs over other dry N forms. Urea manufacture releases few pollutants to the environment. Urea is highly water soluble (at normal atmospheric temperatures, approximately 1 lb of urea can be dissolved in 1 lb of water). 5-Steps of manufacturing Urea: A-Chemical reaction or synthesis step. B-Distillation of the synthesis products to remove un reacted materials. C-Processing as evaporation and prilling or granulation for the urea solution obtained in the distillation operation into the end product A- Chemical reaction step: Urea is produced from ammonia and carbon dioxide in two equilibrium reactions: 2NH3 +CO2 ↔ NH2COONH4 (Fast Reaction) ammonium carbamate NH2COONH4 ↔ NH2CONH2 +H2O (Slow reaction) Urea The first reaction is fast and exothermic and the second one is slow and endothermic. Synthesis step is considered: Heterogeneous (more than one phase) Kinetic limiting one with the rate determined by that of dehydration of ammonium carbamate. Factors affecting this process: 1- Pressure: Since the vapor pressure of carbamate is very high and the overall result of synthesis reaction is decrease in the gas volume, the equilibrium urea yield grows with the increase in pressure . Pressure must not increase above 200 atm, as after 200 atm, cost is increased and the production rate remains constant or increase a little bit. 2-Temerature: At 140º C: yield of urea is low and takes long time. At 150ºC: Yield is better than 140C but also long time. At 180ºC: Yield is improved and takes short time At 200ºC: Is the best , because it is maximum yield at very short time. If T> 200ºC corrosion of equipments could occur. 3- Effect of Excess Ammonia in mole ratio of (NH3:CO2): 2NH3 +CO2 ↔ NH2COONH4 (Fast Reaction) 2 1 1 Excess NH3 above the stoichiometric mole ratio of 2 favors the rate of the reaction because of: The reaction is shifted to the right. Excess Ammonia impedes formation of side products of carbamate hydrolysis. Excess ammonia dissolve in water (from dehydration) so the concentration of water decrease and rate of corrosion decrease. Synthesis reactor The suitable condition is: P=180-200 atm T= 180-200 ºC No Catalyst Synthesis takes place in a tower of alloy steel, which consists of two cylinders, inner and outer. The inner cylinder serves to protect the walls of the outer one from high pressure and corrosion. Reaction occurs inside inner cylinder. Ammonia is fed by a pump in the annular space between the tower and the inner cylinder. Carbon dioxide is fed from the bottom of the inner cylinder. The molten (urea, carbamate, and gases) is removed from the upper part of the inner cylinder and transferred to the distillation column. B-Distillation of the synthesis products In to the distillation column, the excess ammonia and the un reacted products of decomposition of ammonium carbamate are stripped from the urea solution. C-Processing as evaporation and prilling or granulation: Urea solution is concentrated in an evaporator and then to a tank for molten urea fed with steam to avoid caking the urea is produced in either prilling or granulation towers. Prilling The concentrated (99.7%) urea melt is fed to the prilling device (e.g. rotating bucket/shower type spray head) located at the top of the prilling tower. Liquid droplets are formed which solidify and cool on free fall through the tower against a forced or natural up-draft of ambient air. The product is removed from the tower base to a conveyor belt using a rotating rake, a fluidized bed or a conical hopper. Cooling to ambient temperature and screening may be used before the product is finally transferred to storage. Normally mean prill diameters range from 1.6-2.0mm Mechanical strength of prilled particles is weaker than those granulated ones. Modern plants produce granulated particles rather than prilled particles because they are larger and stronger. Granulator (Fluid bed Urea Granulation) Consist of 1 meter thick bed of grannules fluidized by air and supported on a perforated plate. Nozzles spraying urea solution upwards. Fluidized bed is divided in several chambers. Suspended solids move from one chamber to other through the slots between the perforated plates and the partionning walls. Recycled fine and crushed new nuclei is first chamber above bed level. Atomization nozzels use low pressure to spray urea solution. Flow sheet for granulation process: Aqueous urea solution typically from vaccum evaporation. Fluidization air with start up heater. Heated low pressure atomization air. Exhaust air extracted by fan after scrubbing Solids loop. Granules cooled in cooler. Elevator to a screen where the particles are divided into one size and over size. The one size is stored and the over size is recycled to granulator as seeds. Biuret Formation: During the urea formation, biuret is formed as a by-product, according to the equation: 2NH 2CO NH2 +∆ H↔ NH2CONHCONH2+NH3 This is a slow, endothermic equilibrium reaction. The equation shows that biuret formation will take place when there is a high urea concentration, a low ammonia concentration and a high temperature. As biuret is toxic to plants, the biuret content of fertilizer-grade urea will have to be kept as low as possible. This means that at least combinations of the above-mentioned factors will have to be avoided, certainly in places where there is sufficient time for a biuret concentration build-up.