Annotation to the term paper "Optimizing control systems» on the

advertisement

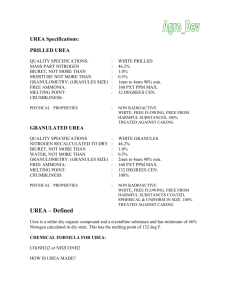

Annotation to the term paper "Optimizing control systems» on the topic of "Optimal control process of synthesis of urea from a two-stage distillation afloat » student groups LA -51s Filichev Olexandr All modern urea production methods based on chemical interaction of ammonia with carbon dioxide and ammonium carbamate decomposition received urea and water. Both reactions proceed in an autoclave at a temperature of 160-200 ° C and a pressure of 120-200 atm, with great heat. The reaction product (water, urea, ammonium carbamate and ammonia that in some processes set with a large excess of urea output increase from 40-50 to 75%) under reduced pressure introduced into another machine. There is separation of the aqueous solution of urea, ammonium carbamate decomposition on outputs and output of ammonia and carbon dioxide them for further separation and recovery to return to production. Let us take the main adjustable parameters as concentration of the solution at the outlet of the housing of vacuum evaporator, since it influences the course of the whole process. Possible regulatory action: - Flow rate of heating agent. - Concentration of a heating agent. A mathematical model of the process: Fp x0 Fx x1 V d ( x1 ) dt Fp С p p Fp С p p 2 ( Fp Fx ) i1 K S ( k p 2 ) V C p Fn (in С k k ) K S ( k p 2 ) Vk k C k d p2 dt d k dt The task of optimal control is control over the evaporation of the urea solution.