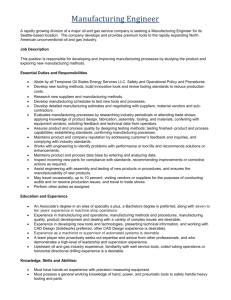

resume - Minda

advertisement

RESUME SANGAPPA. B. KONAPANAVAR NAME: ADDRESS: C/O Mr. S. P. Jagadade, Jeevandhara Hsg Society, Yamunanagar, Nigadi, Pune. Maharastra. CELL: 9552566015 & 9923383774 EMAIL sangappabk@rediffmail.com QUALIFICATION: INSTITUTION: 4-years Diploma in Tool Engineering (GTTC) Govt. Tool Room & Training Centre, Rajajinagar, BANGALORE - 44 YEAR OF COMPLITION: Feb-1985 OVERALL SKILLS: About 24 years experience in - Product Development, - Development of Casting & Forging Parts, - Machining of Castings & Forging parts - Sheet Metal / Fabricated Parts, - Tool Room & Pattern Shop - Work Planning, - Manpower Handling, - Projects Handling - QC Tools / Systems implimation - Familiar with ISO & TS16949 Quality Systems, Software skills: AutoCAD - 2D Catia V5 - 3D Pro – E – 3D Magma soft - Simulation Microsoft Office Microsoft Project EXPERENCE DETAILS: Feb 2012 to till date: Working at Assent Tools, Talewade, PUNE an ISO 9001 company, as co ordinater between Tool maker & Customer. The company is one of the leading Design & Manufacturer of Foundry Tooling, Press Tools, PDC & GDC Dies by 3D & CNC route. The Major Customers are: - Kirloskar Ferrous Industries Ltd, Solapur & Hospet - Mahindra Hinoday Industries Ltd, Pune - Indian Smelting & Refinery Ltd, Pune - Precision Camshafts Ltd, Solapur - Alucast Auto Parts Ltd, Belgaum - SPM Autocomp System Ltd, Pune Responsibilities: - RFQ study & Costing - Design of Tools & Patterns - Layouts & Methodings - Get Approval from Customers - Preparation all 2D & 3D in Design Dept. - Co ordinate with CAM dept & CNC machining - Assembly & Final Inspection - Trials of all Tooling at Customers - Rectification of Toolings - New Customers assignments & new orders. - Correspondents with Customers - Payments collections 2. From April 2011 to Jan 2012 Company: Alucast Auto Parts Ltd. Belgaum. Products: In FG Grade In SG Grade - Camshafts, Brake Drums, Fly Wheels, Turbo Housings. Flange Yokes, Mtg. Brackets, Carriers, Brake Parts. Molding lines – DISA MATCH 130 - HPML, ARPA 450 – Double line Customers: Bosch, Spicer, Ford, Tata Motors, Automotive Axle, Turbo Energy, MUL Job profile: Dy. General Manager Development Responsibilities: -New Product Development (NPD) (In charge of Design Office, Tooling Procurement, and Pattern shop) - Enquiry stage - RFQ Study of part 2D Drg. / 3D model, Feasibility study, & Costing. - Verification stage – APQP Time plan of total project, Freeze of Part Drg. / 3D Model. - Design stage – Tooling, Pattern, Core box, Fixtures, Gauges Approval of all tooling by referring 3D model - Gating Design, Methoding Layout - Pattern layout, Gating Verification by Simulation - Develop Tools & SPMs for Special process - Toolings / Gauges Manufacturing – In house & at Vendors Follow-up with vendors, get tools as per time plan - Toolings Validation & Trials – In-house Achieve of Metallurgy & Dimensions - Process set up – Process Layout / Chart - Sample lot Preparation – PPAP Preparation of all Inspection/Test reports - Approval of PPAP Lot – Feedback from Customer Communicate/Follow up with Customer - Part Productionisation. - Familiar with International Customers requirements, Company standards & Communication & correspondence 3. From Oct 2008 to March 2011 Company: Precision Camshaft Ltd, Solapur, 100% Export Unit Products: Camshafts Supplying to FORD, GM, BMW, MAHALE. Job profile: Manager Development Responsibilities: - Product Development (Incharge of Design Office, Tooling Procurement, and Pattern shop) - Enquiry stage - RFQ Study of part 2D Drg. / 3D model, Feasibility study, & Costing. - Verification stage – APQP Time plan of total project, Freeze of Part Drg. / Model. - Design stage – Tooling, Pattern, Core box, Fixtures, Gauges Approval of all tooling by referring 3D model - Develop Tools & SPMs for Special process - Toolings / Gauges Manufacturing – In house & at Vendors Follow-up with vendors, get tools as per time plan - Toolings Validation & Trials – In-house Achieve of Metallurgy & Dimensions - Process set up – Process Layout / Chart - Sample lot Preparation – PPAP Preparation of all Inspection/Test reports - Approval of PPAP Lot – Feedback from Customer Communicate/Follow up with Customer - Part Productionisation. - Familiar with International Customers requirements, Company standards & Communication & correspondence - Achievements in Present Company - Product Development Time reduced from 16 weeks to 10 weeks by proper planning & monitoring ( Microsoft Project) - Tooling cost reduced by 20% by Improving Tooling design & re costing of tooling cost - Line Rejection reduced by 4% by Improving Toolings 4 .From April 2007 to Oct 2008. Company: Kirloskar Ferrous Industries Limited, Hospet Products: Graded Castings & Machined Castings. Cylinder Heads, Blocks, Housings. Job profile: Manager – Industrial Engineering & Projects Responsibilities: - Process study in Core shop & Mould line Process set up in Core Shop - Time Study & Target set up for each Processes. - Modification in Toolings to increase productivity - New Machine & Equipments procurement & Erection - Plan & Implimation of New Projects. - Search for New Sources & Co ordinate with Purchase Dept. - Deal with International Suppliers, & Arrange for Import of Toolings Equipments - Development of New Vendors - Finalization of Contractors & vendors Rates Achievements in KFIL - Core box change over time for shell machines reduction from 8 hrs to 2 hrs Core box change over time for cold machines reduction from 4 hrs to 1 hr Heater coil assy. & Plug system for all shell core boxes (82 nos) Sand utilization of cold core is increased to 95% from 80% Sand utilization of shell core is increased to 90% from 70% Shell core trimming with help of pneumatic grinders Online assembly of cores on conveyer Fatigue reduction in core & mould shop Reduction in material handling cost 5. From June 2005 to April 2007 Company: Products: Mungi Engineers Pvt Ltd Zaherabad (AP). an ISO-9001-2000 Company. Sheet metal Bodies;/ Pressed & fabricated parts suppliers to M&M. Job profile: Manager Development/ Tool Room & Plant Engineering. Responsibilities: -Product Development, -Preparation of Part drgs. , -Design & Manufacture of required Dies, Jigs & Fixtures. -Process setup. - Approval from customers & productionized -Maintenance of Dies, Jigs & Fixtures -Trouble Shoot & Rectification of Dies, Jigs & Fixtures -Processes Involved - Pressing, CO2 MIG, TIG & Spot welding. -Maintenance of Utilities, Press shop & SPMs . 6. From Nov. 1997 to May 2005. Company: Laxmi Hydraulics Pvt Ltd. Solapur (MH) An ISO 9001-2000 Company Products: Pumps, Motors, FHP Motors. Process Pumps. Job profile: Sr. Engineer R & D. / Manager Machine Shop. Responsibilities: - Devp of Induction Motors, Pumps, Geared Motors. Flp Motors. - Development of Forging, Sheet metal, Plastic, Rubber, Casted Parts for above products -Design & Manufacture of Patterns, Core box, Dies & Fixture --Machining of Pumps, Motors & Geared Motor parts 7. From Dec. 1989 to Oct 1997 about 8 years Company: Premier Filters Pvt. Ltd, Job profile: Sr. Engineer Devp & Tool Room Responsibilities: - Development of Air, Oil & Fuel filter -Product Development, - Preparation of Part drgs. , - Design & Manufacture of required Dies, Jigs & Fabrication. - Approval from customers & productionised - Process Setup. -Maintenance of Dies, Jigs & Fixtures -Trouble Shoot & Ratification of Dies, Jigs & Press shop Machines. -Processes Involved - Pressing, SPMs, CO2 MIG, TIG & Spot welding 8. From May 1985 to Nov 1989. about 3 years Company: ACGL- Goa. Products: Sheet metal/ Fabricated assemblies supplying to Tata Motors Job profile: Tool Room Supervisor/ Tool maker. Responsibilities -Maintenance of Dies, Fixtures, Supplied by Telco -Design & Manufacture of Dies Jigs & Fixtures. - Processes Involved - Pressing, SPMs, CO2 MIG, TIG & Spot welding