course description - Alfred State College intranet site

advertisement

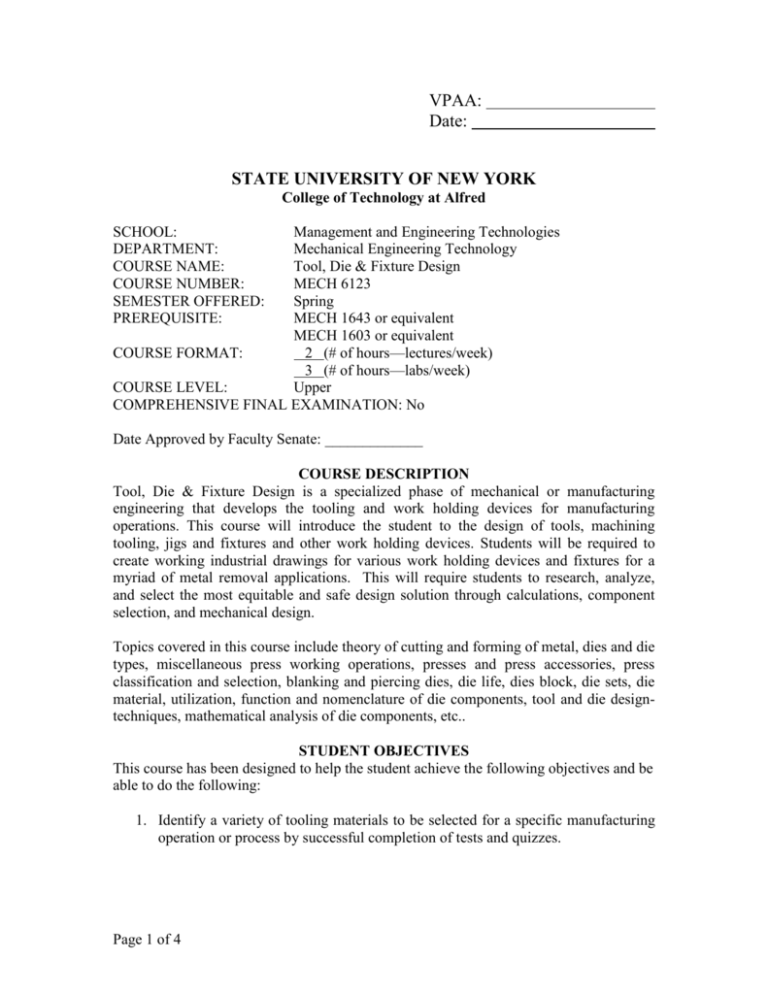

VPAA: Date: STATE UNIVERSITY OF NEW YORK College of Technology at Alfred SCHOOL: DEPARTMENT: COURSE NAME: COURSE NUMBER: SEMESTER OFFERED: PREREQUISITE: Management and Engineering Technologies Mechanical Engineering Technology Tool, Die & Fixture Design MECH 6123 Spring MECH 1643 or equivalent MECH 1603 or equivalent COURSE FORMAT: 2 (# of hours—lectures/week) 3 (# of hours—labs/week) COURSE LEVEL: Upper COMPREHENSIVE FINAL EXAMINATION: No Date Approved by Faculty Senate: _____________ COURSE DESCRIPTION Tool, Die & Fixture Design is a specialized phase of mechanical or manufacturing engineering that develops the tooling and work holding devices for manufacturing operations. This course will introduce the student to the design of tools, machining tooling, jigs and fixtures and other work holding devices. Students will be required to create working industrial drawings for various work holding devices and fixtures for a myriad of metal removal applications. This will require students to research, analyze, and select the most equitable and safe design solution through calculations, component selection, and mechanical design. Topics covered in this course include theory of cutting and forming of metal, dies and die types, miscellaneous press working operations, presses and press accessories, press classification and selection, blanking and piercing dies, die life, dies block, die sets, die material, utilization, function and nomenclature of die components, tool and die designtechniques, mathematical analysis of die components, etc.. STUDENT OBJECTIVES This course has been designed to help the student achieve the following objectives and be able to do the following: 1. Identify a variety of tooling materials to be selected for a specific manufacturing operation or process by successful completion of tests and quizzes. Page 1 of 4 2. Design and select appropriate work holding jigs, fixtures, clamps, etc. consistent with the applicable machining and manufacturing processes function and precision as demonstrated through successful completion of tests and quizzes. 3. Design tooling that is safe and easy to operate and capable of producing manufactured products economically, reliably, and quickly as evidenced by satisfactory completion of design sketches and CAD drawings. 4. Produce design sketches or drawings of various jigs and fixtures. TEXTBOOK(S) Tool Design, Donaldson, Cyril, Current Edition, Glencoe-McGraw Hill. Fundamentals of Tool Design, Current Edition, or 4th Edition, John G. Nee, Society of Manufacturing Engineering, 2003 Supplemental Books Techniques of Pressworking Sheet Metal: An Engineering Approach to Die Design, ISBN: 0-13-900696-6, Donald F. Eary, and Edward A. Reed, Prentice Hall, Copyright 2002 Applied Manufacturing Process Planning: With Emphasis on Metal Forming and Machining, Donald H. Nelson, and George Schneider, ISBN: 0-13-532458-0, Prentice Hall, Copyright 2001. DIVISION OF SUBJET MATTER Topic A B C D E F G H I J K L M N O P Q R Tool Design Tool Materials Cutting Tool Design Workholding Principle Embossing and Miscellaneous Forming Jig Design Fixture Design Miscellaneous Press working Operation Press Classification and Selection Design of workholding tools Types of Die Construction Die Design Techniques Design of Tools for Inspection and Gaging Mathematical Analysis of Die Components Tool Design for Joining Processes Modular Tooling and Automated Tool Handling The Computer in Tool Design Mechanical Handling Devices Page 2 of 4 Lecture Hours 2 2 2 2 1 2 2 1 1 2 1 1 1 1 2 2 1 2 Lab Hours 3 3 3 6 6 6 6 3 6 3 S Exams TOTAL 2 30 45 BIBLIOGRAPHY 1. Blackburn, J., ed. Time-Based Competition: The Next Battleground in American Manufacturing. Homewood, Ill.: Irwin, 1991. 2. Womack, James, Daniel Jones, and Daniel Roos. The Machine that Changed the World. New York: Macmillan, 1990. 3. Deming, W.E. Out of the Crisis. Cambridge, Mass.: MIT Center for Advanced Engineering Study, 1986. 4. Bedworth, D., M. Henderson, and P. Wolfe. Computer-Integrated Design Manufacturing. New York: McGraw-Hill, 1991. 5. Keen, Peter. The Process Edge. Boston: HBS Press, 1997. 6. Monden, Y. Toyota Production System, 2nd Edition, Atlanta, GA: IIE Press, 1993. 7. Taylor, B. W. Introduction to Management Science, 5th Edition. Upper Saddle River, N.J.: Prentice Hall, 1996. 8. Brown, R. G. Statistical Forecasting for Inventory Control. New York: McGrawHill, 1959. 9. Womack, James, and Daniel Jones. Lean Thinking. New York: Simon & Schuster, 1996. Online Tool Design Links http://www.tooldesignworks.com/ http://www.lostfoam.com/services/tool.design.shtml http://www.flomet.com/ http://www.carrlane.com/ http://www.advtool.com/ Page 3 of 4 http://www.ptdmold.com/ http://www.designtoolinc.com/ ______________________________ Dean of School Instructor of Course Page 4 of 4 ______________________________ Department Chair ______________________________ Date