CHAPTER 6

advertisement

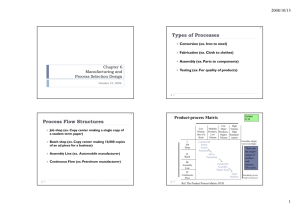

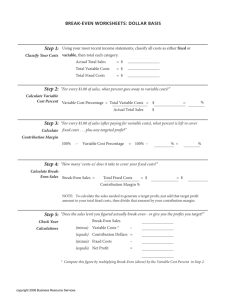

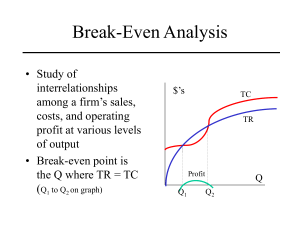

Chapter 06 - Production Process CHAPTER 06 PRODUCTION PROCESSES 8. a. FC = (P - VC) * Break-even (where FC = fixed cost, P = price, and VC = variable cost). $900 = ($5.50 - $4.50) * Break-even Break-even = 900 units. b. FC + profit = (P - VC) * V (where FC = fixed cost, P = price, and VC = variable cost, and V = Volume) $900 + $500 = ($5.50 - $4.50) * V V = 1400 units. c. $0.25 Profit per unit = (P-VC)*V - FC)/V $.25 = (($5.50 - $4.50)*V - $900)/V .25V = V - 900 .75V = 900 V = 1,200 units. a. $0.50 Proit per unit = ((P-VC)*V - FC)/V $.50 = (($5.50 -$4.50)*V - $900)/V .50V = V - $900 .50V = 900 V = 1,800 units. c. $1.50 Profit per unit = ((P-VC)*V - FC)/V $1.50 = (($5.50 -$4.50)*V - $900)/V 1.5V = V - 900 .50V = -900 V = -1,800 units. Not possible. 10. a. FC = (Pc - VCc) * Vc + (Pb -VCb) * Vb where FC = fixed cost Pi = price for product i VCi = variable cost for product i Vi = volume for product i where i is c = chair b = bar stool V = Vc = Vb $20,000 = ($50 - $25) * V + ($50 - $20) * V 20,000 = 25V + 30 V 20,000 = 55V 6-1 Chapter 06 - Production Process V = 364 units of chairs and bar stools. Break-even in dollars = $50(364 + 364) = $36,400. b. FC = (Pc - VCc) * Vc + (Pb -VCb) * Vb where FC = fixed cost Pi = price for product i VCi = variable cost for product i Vi = volume for product i where i is c = chair b = bar stool V = Vc = 4Vb $20,000 = ($50 - $25) * V + ($50 - $20) *4V 20,000 = 25V + 120 V 20,000 = 145V V = 138 units of chairs and (4 * 138) = 552 bar stools. Break-even in dollars = $50(138 + 552) = $34,500. 15. a. throughput time (time to covert raw material into product) Throughput time decreases as you move from a job shop to flow shop environment. b. capital/labor intensity Capital intensity increases as you move to a flow shop (need for more machinery). Labor intensity (assuming you mean # of workers) would probably increase as well (depends on the level of automation). Ratio would increase in a flow shop because capital requirements are so much greater. c. bottlenecks Would probably decrease in a flow shop. 6-2