Manufacturing Process Selection & Design

CHAPTER 7

Manufacturing Process

Selection and Design

1

Overview

Process Selection

Types of Processes

Process Flow Structures

Product-Process Matrix

Break-Even Analysis

Manufacturing Process Flow Design

2

Process Selection

3

Process and Process Selection

Process: Any set of activities performed by an organization that takes inputs and transforms them into outputs ideally of greater value to the organization than the original inputs.

Process selection refers to the strategic decision of selecting with which kind of production processes to have in the manufacturing plant.

4

Process Selection

Three primary questions:

How much variety in products or services will the system need to handle?

What degree of equipment flexibility will be needed?

What is the expected volume of output?

5

Types of Processes

Based on what they do

Conversion process

Iron ore steel sheets, ingredients of toothpaste toothpaste

Fabrication process: changing raw materials into some specific form

Sheet metal car fender, gold a crown for a tooth, cloth

clothes

Assembly process

Assemble parts to components, put toothpaste tubes into a box, fasten a dental crown into someone’s mouth

Testing process

For quality of products

6

Process Types

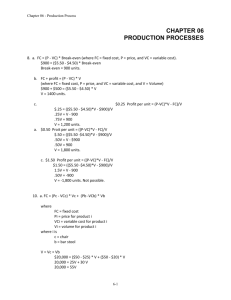

A process flow structure refers to how a factory organizes material flow using one or more of the process technologies.

Job shop

Batch shop

Assembly Line

Continuous Flow

7

Job Shop

Job shop: A process structure suited for low-volume production of a great variety of nonstandard products .

Each job may require a different set or sequence of processing steps

High flexibility of equipment (General-purpose equipment )

Skilled workers

Examples: commercial printing firms, copy center making a single copy of a student term paper, airplane manufacturers, machine tool shops, American Chopper

8

Batch Shop

Batch shop: A process structure that produces a moderate variety of standard products at relatively low volumes .

A somewhat standardized job shop

Employed when a business has a relatively stable line of products

The products are produced periodically in batches to reduce the impact of setup time on equipment

The equipment need NOT be as flexible as in a job shop

The skill level of workers need NOT to be as high as in a job shop

Examples:

Bakeries: make bread, cakes, cookies in batches;

Movie theatre: shows movies to groups (batches) of people;

Airlines: carry batches of people from airport to airport;

Other examples: production of beer, book, magazine, etc

9

Assembly Line

Assembly line (Repetitive processing):

A process structure designed to make discrete parts moving through a set of specially designed workstations at a controlled rate .

High volume

Standardized products

Slight flexibility of equipment

Skill of workers is usually low

Examples: manual assembly of toys and appliances, automatic assembly of components on a printed circuit board, production line (automobiles, computers, etc.)

10

Example: Production Line

11

Continuous Flow

Continuous flow: An often automated process structure that converts raw materials into finished product in one continuous process .

Highly standardized products, no variety

Special-purpose equipment (no need for equipment flexibility)

Skill of workers is low

Examples: petroleum, steel, sugar, flour, and salt

12

Example: Continuous Flow

13

Product-Process Matrix

Choice of process flow structure is based on two main considerations:

Variety—how much the product changes from customer to customer;

Volume of demand.

Product-process matrix: Shows the relationship between process structures and product volume and variety characteristics.

As volume increases and the product line narrows, specialized equipment and standardized material flows become economically feasible. (see next slide)

14

Product-Process Matrix

Exhibit 7.1

High

Variety

Low

Low Volume

15

High

Break-Even Analysis

16

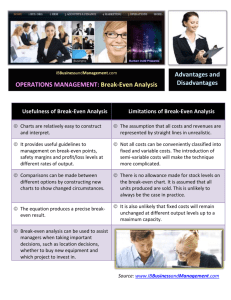

Break-Even Analysis

A standard approach to choosing among alternative processes or equipment.

Most suitable when processes and equipment entail a large initial investment and fixed cost, and when variable costs are reasonably proportional to the number of units produced.

Break-even Point (BEP)

One option case: determine the point in units (produced and sold) at which total cost = total revenue.

Multiple options case: determine the points in units at which one option is indifferent to another.

17

Cost-Volume Relationships (Total Cost)

Fixed cost (FC)

0

Q (Quantity in units)

Total cost (TC) = Fixed cost (FC) + Variable cost (VC)

= Fixed cost (FC) + Unit cost (v) X Quantity (Q)

18

Revenue-Volume Relationships (Total Revenue)

0

Q (Quantity in units)

Total revenue = Revenue per unit (R)

X

Quantity (Q)

19

Cost-Volume Relationships (BEP)

0 BEP Q (volume in units)

Break-even point (BEP): the quantity of output at which total cost and total revenue are equal.

20

One-Option Case

Find out the quantity that makes:

Total Revenue (TR) = Total Cost (TC)

Total Revenue = Total Fixed Cost + Total Variable Cost

Unit Revenue* Units = Total Fixed Cost + Unit Cost* Units

R * Q = FC + v * Q

Break Even Quantity: Q

BEP

= FC / (R – v)

Profit (margin) = Total Revenue – Total Cost

21

Example -- One-Option Case

Suppose you want to purchase a new computer that will cost $5,000.

It will be used to process written orders from customers who will pay $25 each for the service. The cost of labor, electricity and the form used to place the order is $5 per customer.

How many customers will we need to serve to permit the total revenue to break-even with our costs?

FC = $5,000, R = $25/customer, v = $5/customer

Break-even quantity Q

BEP

:

= FC /(R-v) = 5,000/(25-5)

= 250 customers

How many customers should we serve to make a profit of $1,000?

Profit = Total Revenue – Total Cost

= R * Q – (FC + v * Q) = (R-v) * Q - FC

1,000 = (25-5) * Q – 5,000

Q = 300 customers

22

Example -- Multiple-Option Case (page 207)

Suppose a manufacturer has identified the following options for obtaining a machined part:

1. purchase the part

$200/unit, no fixed cost

2. make the part on a semiautomatic lathe

$75/unit, fixed cost = $80,000

3. make the part on a machining center

$15/unit, fixed cost = $200,000

Which option should the manufacturer choose?

TC_buy = 200 * Q

TC_lathe = 80,000 + 75 * Q

TC_machine = 200,000 + 15 * Q

23

Example -- Multiple-Option Case (page 207)

500000

400000

TC_Lathe

TC_Machine

300000

200000

TC_Machine

TC_Lathe

B

100000

TC_buy

A

0

0 300 600 900 1200 1500 1800 2100

Demand < B Buy

B < Demand < A Semiautomatic Lathe

Demand >A Machine center

2400

24

Example -- Multiple-Option Case (page 207)

Break-even point B:

Total cost of “buy” = Total cost of “Make on lathe”

200 x Demand = 80,000 + 75 x Demand

Demand

B

= 80,000/(200-75) = 640 units

Break-even point A:

Total cost of “Make on lathe” = Total cost of “Make on machine”

80,000 + 75 x Demand = 200,000 + 15 x Demand

Demand

A

= (200,000- 80,000)/(75-15) = 2,000 units

25

Manufacturing Process

Flow Design

26

Manufacturing Process Flow Design

A process flow design can be defined as a mapping of the specific processes that raw materials, parts, and subassemblies follow as they move through a plant.

The most common tools to conduct a process flow design include assembly drawings, assembly charts, operation and

route sheets, and process flowcharts.

27

Assembly Drawing

An assembly drawing is simply an exploded view of the product showing its component parts.

Plug assembly drawing

28

Assembly Chart

An assembly chart uses the information presented in the assembly drawing and defines how parts go together, their order of assembly, and often the overall material flow pattern.

Assembly chart for plug assembly

29

Operation and Route Sheet

An operation and route sheet specifies operations and process routing for a particular part. It conveys such information as the type of equipment, tooling, and operations required to complete the part.

Operation and route sheet for plug assembly

30

Process Flowchart

A process flowchart denotes what happens to the product as it processes through the productive facility.

Process flowchart for plug housing

31

Recap

Process

Process selection

Types of processes

Process flow structures

Job shop

Batch shop

Assembly line

Continuous flow

Product-process matrix

Break-even point (BEP)

One-option case

Multiple-option case

Manufacturing process flow design

32