Chapter 5

advertisement

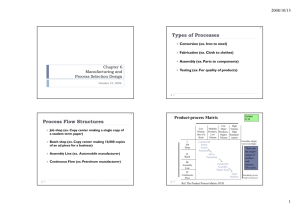

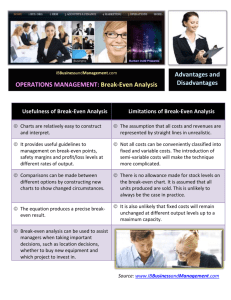

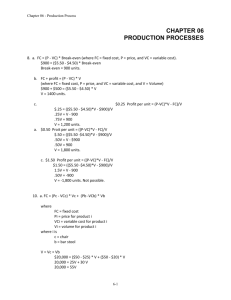

MBA 8452 Systems and Operations Management Product Design & Process Selection — Manufacturing Introduction to Operations Management/ Operations Strategy Process Analysis and Design Project Management Process Analysis Planning for Production Process Control and Improvement Capacity Management Quality Management Aggregate Planning Job Design Just in Time Manufacturing Layout/ Assembly Line Balancing Services Statistical Process Control Scheduling Inventory Control Supply Chain Management Waiting Line Analysis 2 Objective: Manufacturing Design Describe the Manufacturing Process Categories Explain The Product-Process Matrix Describe the Changes in Process Design Calculate Break-Even Analysis 3 Product Design Process Concept Development Product Planning Detailed Engineering Engineering Release (Sign-Off) 4 Improving Product Design: Concurrent Engineering Definition cross-functional coordination, integration, and simultaneous development of product Benefits reducing time to market decreasing cost improving quality and reliability 5 Traditional Design vs. Concurrent Design Traditional design: walls between functional areas customers Marketing Design Engineers Manuf. Engineers Production Concurrent design: break down the walls between functional areas 6 Improving Product Design: Quality Function Deployment Translate the “voice of the customer” into technical design requirements Use interfunctional teams from marketing, engineering, and manufacturing Basic tool--House of Quality 7 House Of Quality 5. Tradeoff Matrix Importance 3. Product characteristics 1. Customer requirements 4. Relationship matrix 2. Competitive assessment 6. Technical assessment and target values 8 Correlation: 5 X * Water resistance Energy needed to open door Check force on level ground Door seal resistance Energy needed to close door 3 Negative Strong negative X X X Competitive evaluation X = Us A = Comp. A B = Comp. B (5 is best) 1 2 Easy to close 7 X Stays open on a hill 5 X AB Easy to open 3 Doesn’t leak in rain 3 No road noise 2 3 4 5 AB 2 XAB A XB 4 10 Importance weighting 6 6 X A 9 2 3 Relationships: 4 3 2 1 X B BXA BA X BA X A Maintain current level Technical evaluation (5 is best) B Maintain current level 5 Reduce energy to 7.5 ft/lb. 6 Reduce force to 9 lb. Target values Maintain current level Strong = 9 Reduce energy level to 7.5 ft/lb 1 Positive X Engineering Characteristics Customer Requirements Strong positive X Accoust. Trans. Window House of Quality: An Example B A X X A Medium = 3 Small = 1 B Improving Product Design: Design for Manufacture & Assembly Value Analysis/Value Engineering (VA/VE) focus on the ratio of value to cost Guidelines Simplification (fewer parts) Standardization (more standard parts) Modular design (combining parts) 10 Types of Processes Project Assembly line Job shop/Batch production Continuous process 11 Product - Process Matrix Product Characteristics One-of-a Kind Type of Process Project Low Vol Low Std Movie production Job Shop High flexibility & unit cost Printing shop Fast food restaurant Batch Auto assembly Assembly Line Continuous Multiple Limited Products High Volume Products High Volume High Demand Low flexibility & unit cost Oil, sugar refinery 12 Process Selection Break-even Analysis Single Process--Adopt it or not? Break-even point: Profit=0 ------> demandBE=? Two Processes--Which one is better? Cross-over point: Profit1=Profit2 ------> demandCO=? 13 Break-even Analysis Example--I Tom Smith, a recent graduate of GSU, has just formed a company called the New Age Surf to provide high speed internet access with a competitive price of $20 per month. The fixed cost each month is estimated to be $60,000. Unit cost for each customer is approximately $10 per month. How many customers must be attracted in order to break even? 14 Break-even Analysis Example--II Suppose now Tom is given another option. Instead of purchasing equipments, he can rent them from other companies. This will reduce the monthly fixed cost to $20,000. But unit cost for each customer will be $15 per month. What option should Tom adopt? 15