Compliance Matrix 1B - Coastal REEL

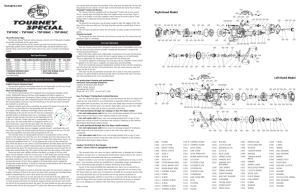

advertisement

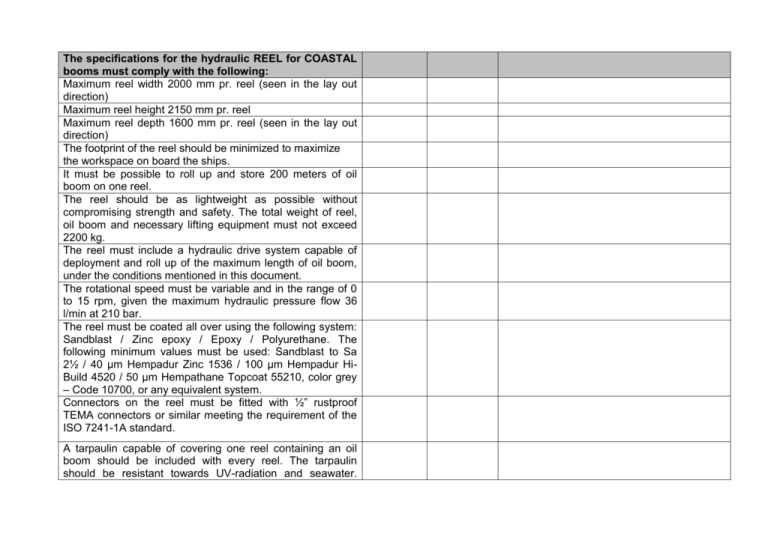

The specifications for the hydraulic REEL for COASTAL booms must comply with the following: Maximum reel width 2000 mm pr. reel (seen in the lay out direction) Maximum reel height 2150 mm pr. reel Maximum reel depth 1600 mm pr. reel (seen in the lay out direction) The footprint of the reel should be minimized to maximize the workspace on board the ships. It must be possible to roll up and store 200 meters of oil boom on one reel. The reel should be as lightweight as possible without compromising strength and safety. The total weight of reel, oil boom and necessary lifting equipment must not exceed 2200 kg. The reel must include a hydraulic drive system capable of deployment and roll up of the maximum length of oil boom, under the conditions mentioned in this document. The rotational speed must be variable and in the range of 0 to 15 rpm, given the maximum hydraulic pressure flow 36 l/min at 210 bar. The reel must be coated all over using the following system: Sandblast / Zinc epoxy / Epoxy / Polyurethane. The following minimum values must be used: Sandblast to Sa 2½ / 40 µm Hempadur Zinc 1536 / 100 µm Hempadur HiBuild 4520 / 50 µm Hempathane Topcoat 55210, color grey – Code 10700, or any equivalent system. Connectors on the reel must be fitted with ½” rustproof TEMA connectors or similar meeting the requirement of the ISO 7241-1A standard. A tarpaulin capable of covering one reel containing an oil boom should be included with every reel. The tarpaulin should be resistant towards UV-radiation and seawater. Similar color as the reel. Feet and attachments on the reel should fit the attachment fittings on the ships deck, see drawing no. 1 The reels are fastened in the attachment fittings using heavy duty lock hooks. Support feet: 80 x 80 mm It should be possible to secure the reel using bolts thought feet and attachment fittings, see drawing no. 1 Connectors on the reel must be fitted with ½” stainless steel (AISI 316L) TEMA connectors or similar. No electrical components are allowed on the equipment. All steel must be grade A. All aluminium must be seawater resistant, AlMg4,5 Mn or similar. All work done and delivered must comply with the Danish and international regulations including the Danish maritime Authority “Danish Maritime Authority: Notice F, chapter VI of October 2006; Crew protection, occupational health and safety, etc.” The hydraulic reel must be CE-certified