Separation of Pigments by TLC and Column Chromatography

advertisement

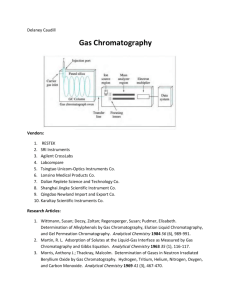

Fischer Esterification: Synthesis of Oil of Wintergreen Introduction Natural flavors and fragrances tend to be complex mixtures –“banana” has at least two dozen components, for example – but often one or a very few of the components offer a pretty good duplication. Interestingly, only a very few functional groups are commonly found in pleasant flavors and fragrances, and of those, esters are predominant. Examples shown in Figure 1 include banana, pineapple, apple, cherry, plum, apricot, strawberry, pear, honey, wintergreen, and even rum and “wine”. Some esters – ethyl acetate, butyl acetate, pentyl acetate, and isopentyl acetate are examples – are components of many natural fragrances. * O O H O O butyl formate plum H butyl acetate pineapple ethyl formate rum O O O O methyl butyrate apple O pentyl acetate banana ethyl acetate "wine" O O butyl propanoate apricot butyl isobutyrate pineapple O O O O O O O O isopentyl acetate banana O O O O O butyl pentanoate apple ethyl isopentanoate apple butyl isopentanoate apple O O O O O allyl benzoate cherry O allyl phenylacetate honey OH O benzyl butyrate pear O phenethyl acetate honey O OH O methyl salicylate wintergreen O O isopentyl salicylate strawberry Figure 1. Representative esters and the “flavor type” of each. * When you see food flavorings labeled “imitation”, you know that flavor came from a chemical company that used some specific chemical processes to make the flavoring. And if the key chemical is an ester, it’s a good bet that it was made from an acid by “esterification” – the reaction used to transform an acid into an ester. By the Written by John McCormick, Department of Chemistry, University of Missouri-Columbia. *Source: Fenaroli, Gioanni, Fenaroli’s Handbook of Flavor Ingredients, Furia, Thomas E., and Nicolo Bellanca, Eds. The Chemical Rubber Co., Cleveland, 1971, pp 643 – 672. way, it is interesting that while esters generally smell great, the carboxylic acids they are made from often have sharp (think vinegar) or bad (think sour milk) odors. In this laboratory, you will do an esterification reaction (Equation 1) that transforms salicylic acid into methyl salicylate (oil of wintergreen). OH O OH COH O COCH3 (1) methyl salicylate salicylic acid Synthesis of Esters There are several procedures to make esters from the carboxylic acids. Among them, one – Fischer esterification – has been used by chemists for well over a century because it gives highs yields and lends itself to large-scale commercial use as well as very small scale research use. As indicated in Equation 2, Fischer esterification is based on an equilibrium reaction (actually, a series of reactions), which means that something has to be done to cause the equilibrium to strongly favor product formation. If the goal is a high-yield conversion of the carboxylic acid into the ester, there are two options to shift the equilibrium toward ester formation: use a large excess of the alcohol, or remove one of the products as the reaction proceeds. When the esterifying alcohol is cheap and abundant, chemists use it in large excess, as you will in this lab. Alternatively, because water is one of the two products and there are good ways to remove water, this also is a commonly used strategy. O (2) RCOH + H+ ROH O RCOR + H2O Mechanism of Fischer Esterification The mechanism (Equation 3) of the Fischer esterification reveals that it is a typical nucleophilic substitution at acyl C=O: a substitution reaction that takes place by an initial addition of alcohol to the carbonyl group to form a tetrahedral intermediate (II) and a subsequent elimination of water, which re-forms the carbonyl group. The net result of this addition-elimination process substitutes OR for OH. The mechanistic details shown in Equation 3 emphasize the catalytic role of acid, first in increasing the rate of addition of alcohol to the acid (I) and then in increasing the rate of loss of water from intermediate II to form the ester (III). O + OH H3 O+ RCOH I RCOH + OH OH OH RCOH + RCOH RCOH H2O ROH ROH + H2O + + H3 O RO II + (3) OH H3 O+ OH + OH2 OH RCOH RC RO II RO RCOR + + + H2O H2O + OH RCOR H 2O O RCOR III + + H3 O Analysis of Products by Gas Chromatography Once you obtain your product, how do you know that it has the expected structure and that it is pure? Well, IR spectroscopy comes to mind as useful: The OH group, easily observed in the IR spectrum, of the starting carboxylic acid should be absent in the IR spectrum of the product. In addition, the fingerprint region of the IR should be an exact match with that of an IR taken of an authentic sample of your product. However, if your product is contaminated by something else (including a small amount of starting carboxylic acid), the fingerprint region will have additional peaks and therefore will be deceptive. Gas-liquid chromatography, often simply called gas chromatography (GC), offers an alternative analytical technique that lets you assess not only whether your product has the expected structure but also just how pure your product is. Compared to the other two types of chromatography that you have seen – thin layer chromatography (TLC) and column chromatography – GC is much more sensitive (It will detect a far smaller amount of material.) and is much more effective for separating molecules, even those having nearly identical structures. Appendix A is devoted to a brief overview of gas chromatography, which you will use to analyze your final product. Distillation Figure 2 shows the apparatus you should use for distillation. Be sure to use a thermometer adaptor. (Ask your TA if you are uncertain what this is.) Also be sure your distillation apparatus is NOT a closed system! When heated, the expanding gas in a closed system will blow it up! condenser distillation head r in ring stand clamp ring stand round-bottom flask bent adapter wate thermometer adapter ring stand wate r ou t thermometer clamp clamp heating mantel lab jack (to raise & lower heat) Erlenmeyer flask Experimental Procedure Safety Notes! Solutions of H2SO4 are extremely corrosive. Avoid contact with skin and clothing. In case of accidental contact, rinse the affected area with copious amounts of cold water. Salicylic acid and methyl salicylate are toxic and may be absorbed through the skin. Avoid breathing dust, ingestion, and contact with the skin. In case of accidental skin contact, flush with copious amounts of water. Dichloromethane is toxic and has been categorized as a carcinogen. Avoid inhalation, ingestion, and contact with skin. In case of accidental contact, wash with copious amounts of water. Synthesis of Methyl Salicylate Weigh 3.45 g of salicylic acid and 15 mL of methanol in a 50-mL round bottom flask. Swirl to dissolve the salicylic acid, using a hot water bath to heat the mixture as needed to completely dissolve the acid. Then add to the cool methanol solution 5 mL of conc. H2SO4 in small portions, taking care to see that the mixture does not get too hot to touch the flask. You may observe formation of a white precipitate. Add an acid-resistant boiling chip and reflux the reaction mixture for 1 hour. Use a cold-water bath to cool the reaction mixture to room temperature. Add 25 mL of H2O to a separatory funnel and then, using a funnel, pour your reaction mixture into the separatory funnel. Add 10 mL of dichloromethane to the emptied reaction flask, swirl to rinse it, and pour it into the separatory funnel. Carefully (frequent venting!!) shake the separatory funnel to extract your product, allow the layers to separate, and collect the dichloromethane layer (Which layer is it?) in a 50-ml Erlenmeyer flask. Repeat the extraction two more times, each time using 10 mL of dichloromethane and collecting all three extracts in the same Erlenmeyer flask. Drain the aqueous layer into a beaker (larger than 100 mL capacity) labeled “Waste aqueous solutions.” Pour the dichloromethane solution of unpurified methyl salicylate into the separatory funnel, and wash twice with 15 mL of H2O, then twice with 15 mL of 5% NaHCO3 solution (Careful!! Vent frequently! You may see substantial evolution of CO2 as you neutralize any remaining acid.), and once with 15 mL of saturated NaCl solution. Note: For each wash, you will keep the lower layer and drain the upper, aqueous layer into the “Waste Aqueous Solutions” beaker. Drain the washed dichloromethane solution into an Erlenmeyer flask. (Be careful to avoid letting any H2O drain into the flask.) Add a small amount of Na2SO4 (drying agent) and swirl the flask. Add additional Na2SO4 if necessary until some of the drying agent does not form in a clump. Allow the mixture to stand 10 minutes, and then filter it through a funnel with cotton (or glass wool) loosely stuffed in the stem into a tared (You must know its weight!) 50-mL round bottom flask. Remove the dichloromethane using a rotovap and weigh your crude (unpurified) methyl salicylate. Weigh your sample of crude methyl salicylate and characterize it using both IR spectroscopy and gas chromatography. Please remember that you need to compare the retention time and purity of your sample to the known standards. Explain any addition peaks that show up in the chromatogram and in the IR as compared to the standards!!!! Clean up Discard all wastes in the appropriately labeled containers. No materials from this experiment go down the drain! After you have poured all you can into the waste containers, wash glassware containing only residual amounts (clinging to the sides of the glassware) in the sink. Appendix A: Gas Chromatography You will use gas chromatography (GC) to check the purity of your methyl salicylate (product) prepared by the Fischer esterification reaction. GC works on the same principles as TLC and column chromatography (see description in the chromatography lab), but for GC the mobile phase is a gas and the stationary phase is a liquid. The components of the sample are continually partitioned between the vapor phase and the liquid phase. Because the molecules that spend a greater proportion of time in the gas phase elute more rapidly, compounds with higher vapor pressure (lower boiling point) elutes faster than those with lower vapor pressure (higher boiling point). The chromatography column is housed in an oven so that the temperature may be controlled anywhere up to about 300 °C. Because vapor pressure increases with heating, compounds elute faster when the temperature of the oven is increased. The length of time that a compound is retained in the column is known as its retention time (TR), which can be used to help identify the compound, in the same manner as the TLC Rf value. Two of the most common stationary phases used for GC are non-volatile polymers: dimethylsilicone (nonpolar) and polyethylene glycol (moderate polarity). CH3 O Si CH3 CH3 O O Si CH3 CH2 CH2 n n Polyethylene glycol Trade name: Carbowax Dimethylsilicone Trade names: SE-30, OV-1 These liquid phases are coated on the surface of an inert support material and packed in a column made from glass or metal tubing. A schematic diagram of a gas chromatography system is given in Figure 1. The column is coiled and kept in an oven where the temperature can be controlled. The mobile phase, called the carrier gas, (generally helium) flows through the column. The sample is injected (using a syringe) onto the column through the injection port at the upstream end of the column. Only small amounts of sample are used, usually between 0.5 – 5 l. A detector at the end of the column generates a signal when a compound elutes – this is recorded Column h Oven w1/2 Detector He in Area = w1/2 x h Recorder Inject sample Figure 1. The components of a typical gas chromatograph. The recorder prints the chromatogram, which has a peak for each component, proportional in area to the amount of that compound present in the mixture. Right: A method for determining peak areas. using a strip-chart recorder. Several types of detectors are available. You will be use a gas chromatograph equipped with a thermal conductivity ("hot-wire") detector. This detector consists of a wire placed across the end of the column. The electrical resistance of the wire depends on its temperature. When only the helium carrier gas is passing over the wire, the voltage level is constant, which results in a straight line on the recorder. When a component from the mixture elutes from the column and passes over the wire, it causes a change in the wire temperature, which causes a change in the voltage, which causes a change in the signal sent to the recorder. Therefore, each component eluting from the gas chromatograph appears as a peak on the recorder trace, called the chromatogram. The area of each peak is proportional to the amount of that compound – if twice as much sample is injected, the areas of the peaks double. Therefore, the peak areas can be used as a quantitative measure of the amount of each component in the mixture. Your GC chromatogram will show a peak for your ester (product) and for the unreacted alcohol, if any contaminates your product. In addition, a small amount of air is always injected along with the sample, and this also gives a small peak. Since air spends all of its time in the mobile phase, the TR for the air corresponds to the time required for the helium to pass through the column.