Centrifuges - University Wiki

advertisement

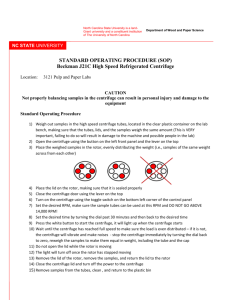

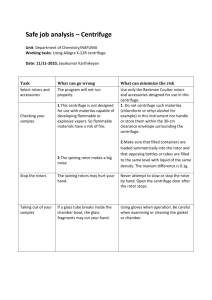

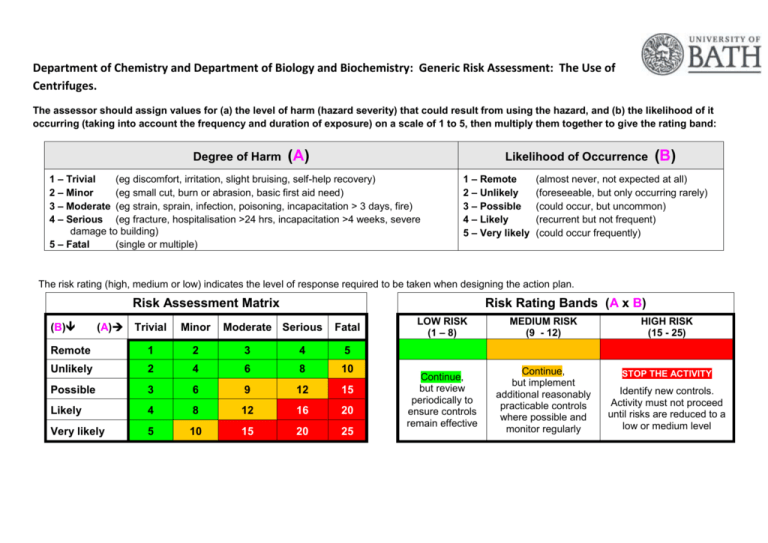

Department of Chemistry and Department of Biology and Biochemistry: Generic Risk Assessment: The Use of Centrifuges. The assessor should assign values for (a) the level of harm (hazard severity) that could result from using the hazard, and (b) the likelihood of it occurring (taking into account the frequency and duration of exposure) on a scale of 1 to 5, then multiply them together to give the rating band: Degree of Harm (A) Likelihood of Occurrence 1 – Trivial (eg discomfort, irritation, slight bruising, self-help recovery) 2 – Minor (eg small cut, burn or abrasion, basic first aid need) 3 – Moderate (eg strain, sprain, infection, poisoning, incapacitation > 3 days, fire) 4 – Serious (eg fracture, hospitalisation >24 hrs, incapacitation >4 weeks, severe damage to building) 5 – Fatal (single or multiple) 1 – Remote 2 – Unlikely 3 – Possible 4 – Likely 5 – Very likely (B) (almost never, not expected at all) (foreseeable, but only occurring rarely) (could occur, but uncommon) (recurrent but not frequent) (could occur frequently) The risk rating (high, medium or low) indicates the level of response required to be taken when designing the action plan. Risk Assessment Matrix (B) (A) Risk Rating Bands (A x B) Trivial Minor Moderate Serious Fatal Remote 1 2 3 4 5 Unlikely 2 4 6 8 10 Possible 3 6 9 12 15 Likely 4 8 12 16 20 Very likely 5 10 15 20 25 LOW RISK (1 – 8) MEDIUM RISK (9 - 12) HIGH RISK (15 - 25) Continue, but review periodically to ensure controls remain effective Continue, but implement additional reasonably practicable controls where possible and monitor regularly STOP THE ACTIVITY Identify new controls. Activity must not proceed until risks are reduced to a low or medium level Risk Assessment of: Centrifuge use at Bath University. Assessor(s): Overview of activity / location / equipment / conditions being assessed: The use of centrifuges in any experimental/ research work in the Department of Chemistry or Department of Biology and Biochemistry at the University of Bath. Centrifuge summary: A laboratory centrifuge is a piece of equipment, generally driven by a motor that puts an object in rotation around a fixed axis, applying force perpendicular to the axis. The centrifuge works using the sedimentation principle, where the centripetal acceleration is used to separate substances of different density or particle size. Hazard Who could be harmed? How could they be harmed? Mechanical Laboratory users, staff, support staff, PG and UG students, contractors and/ or visitors to the laboratory. Mechanical failure of rotor parts (often violent) Small differences in mass of the load can result in a large force imbalance when the rotor is at high speed. This force imbalance strains the spindle and may result in damage to centrifuge or personal injury. Centrifuge rotors should never be touched while the Work Authorised by: Risk Before controls Implemented A B AxB Date: Control measures needed to minimise risk PPE – Lab coat and glasses must be worn at all times. All operators should be trained on proper operating procedures before operating the centrifuge. A risk Assessment must be filled in, understood and signed before operating any centrifuge. Before used check the rotor, lids and seals are clean and no damage. A build-up of chemicals from spillages may cause tube to jam in rotor or corrosion which could lead to rotor failure. Damages rotors must not be used and should be reported to the person in charge of the centrifuge. Risk after controls implemented A B AxB rotors are moving, because a spinning rotor can cause serious injury. Electrical Electric Shock Centrifuges should be visually inspected before use and any concerns reported to workshop staff. Centrifuge must not be used until a competent person has confirmed the oven is safe. PAT testing must be up-to-date. Centrifuges must be used as per manufacturer’s instructions. Centifuges should be switched off when not in use. Plugs should be labelled as to the equipment/ rig that they power and should be easily accessible in an emergency situation. Leads should not be left trailing. Use as per manufacturer’s instruction. Fire or explosion Fires can occur if centrifuges are not cleaned regularly, if samples are not loaded correctly or not used as per manufacturer’s instructions. Check tubes and bottles for cracks and deformities before each use. Never fill centrifuge tubes above the maximum recommended by manufacturer. (refer to instruction manual ) Never exceed the maximum stated speed for any rotor. Always use sealed safety cups or sealed rotors with O-rings when working with infectious agents. Wipe exterior of tubes or bottles with disinfectant prior to loading. Open rotor in biological safety cabinets when working with infectious agents. Stop the centrifuge immediately if an unusual condition (noise or vibration) begins. Decontaminate safety carriers or rotors and centrifuge interior after each use. Chemical Exposure to chemicals. Cuts and grazes From material or broken vessels in centrifuge. All work with hazardous chemicals should be Risk Assessed. Any spills should be cleaned up as detailed in the chemical MSDS. Any biological spills should be decontaminated according to the RA. Centrifuges should be cleaned regularly using appropriate PPE. All breakages should be cleared up immediately.