Lecture 3 Centrifuge

advertisement

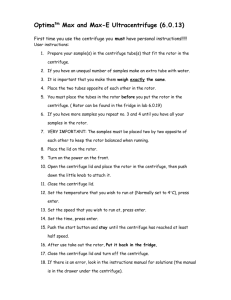

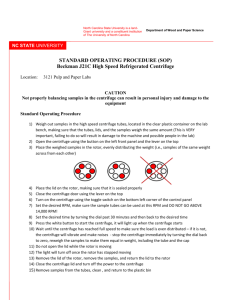

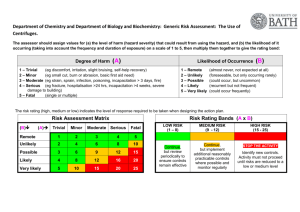

Centrifuges Topics Principle of Operation Diagrams Applications Types of Centrifuges History Safety Operation Preventive Maintenance Common Failures Basic Troubleshooting Principle of Operation A centrifuge is a piece of equipment, generally driven by an electric motor, that puts an object in rotation around a fixed axis, applying a force perpendicular to the axis to separate substances of different densities. Tubes in the centrifuge are tilted so centrifugal force can pull denser substances towards the bottom of the tube. Relative Centrifugal Force (RCF) measures acceleration applied to the sample RCF=(r*ω2)/g r=distance from center or motor to sample ω= angular velocity (radians/ second) g=9.8m/s2 Principle of Operation Inputs Outputs AC Voltage Rotating Rotor Mixed Solution Density Separated Layers Diagrams Rotor Power LED Timer Diagrams Power Source Motor Power Distribution Board Timer Safety Switch Power Indicator LED Applications Separate solids from solution Used during urinalysis to separate disease identifying components Separate blood into plasma and cellular components Types of Centrifuges Centrifuges are generally divided into 3 categories based on their maximum attainable speed: 1. "Low-speed": max ~5 x 103 rpm. 2. "High-speed": max ~2 x 104 rpm. 3. "Ultracentrifuges": max ~105 rpm Others Variable Temperatures Vacuum Capabilities History English military engineer Benjamin Robins (1707-1751) invented a whirling arm apparatus to determine drag. In 1864, Antonin Prandl invented the first dairy centrifuge in order to separate cream from milk. In 1879, Gustaf de Laval demonstrated the first continuous centrifugal separator, making its commercial application feasible. Safety Always use PPE. Before using, read the owner's manual. Do not operate a centrifuge until having been shown proper use by an experienced operator. Check that the centrifuge chamber and drive spindle of the rotor are free of scratches or burrs. Decontaminate centrifuge of biological hazards before servicing. Safety Never repair a cracked or bent rotor. If rotor has been replaced, tighten knob/screw fastening rotor to the shaft to prevent hazardous loosening. Prolonged contact w/ some disinfectants can cause damage to rotor and other components (e.g. 10% sodium hypochlorite). Never attempt to touch or stop a spinning rotor by hand or with another tool or object. Operation Place tubes in centrifuge. Always use correct size tubes to prevent tube damage. Always using a counterbalance: By mass NOT volume Put the tubes opposite each other in the centrifuge. If you have more than two tubes, only the ones opposite each other have to be equal in mass. If centrifuge has variable speeds, enter RPM. Close lid. Turn timer on or press start. Remove the tubes carefully after the centrifuge has completely stopped spinning to prevent remixing. Operation Result of unbalanced centrifuge Preventive Maintenance Lubricate and clean motor. Clean case. Inspect power cords and plugs. Inspect controls and switches. Ensure appropriate menu settings for proper use. Ensure tightness of rotor. Check lights and indicators. Verify that alarms are operating properly. Ensure safety switch is functioning. If refrigerated, ensure temperature reading is working. Replace/repair gaskets, seals, and vacuum pump (if applicable). Common Failures Machine will not start. Power supply is faulty. Safety switch or timer not working properly. Motor not working properly. Motor making noise. Rotor is broken. Lid will not open or close. Basic Troubleshooting See flow chart.