Design centrifuge

advertisement

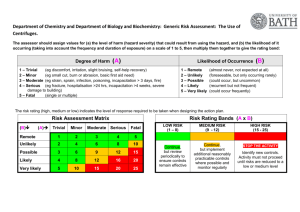

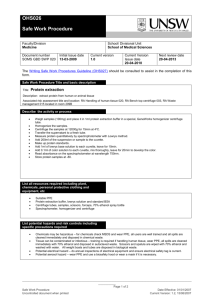

Disk Stack Centrifuge Rachel Robitaille Recovery Process Centrifugation is the first step in the recovery of the insulin precursor from the fermentation broth The goal of the recovery is to obtain a stable intermediate product for further processing Principles of the Fermentor The fermentor is inoculated as a fed-batch process 3 days later the culture is grown as a continuous fermentation in a simple medium containing yeast extract as its main nitrogen source The yeast secretes the insulin precursor into the fermentation broth, making disruption of the S.Cerevisiae cells unnecessary The insulin precursor is recovered from the fermentation broth on a continuous basis Principles of the Centrifuge Disk type centrifuges consist of a vertical stacks of thin disks in the shape of cones The sedimentation takes place in the radial direction in the space between adjacent cones This reduces the settling distance and increases the rate at which the material is separated Centrifuge Variables Disk Stack Centrifuges may contain 2 or 3 disks. Ours will have 2 in order to remove the solid yeast cells from the liquid broth They can process batch or continuous feeds Very effective at removing solids but do not account for dissolved solids or heavy metal species in solution Specifications Assuming a batch process, the centrifuge would need to be able to hold at least 650,000 L Assuming a continuous process where the amount of feed in one day is equivalent to that of a batch process, the centrifuge would need to be able to hold at least 8000 L. Approx 100 L would be expelled as solid waste containing yeast cells The rest would go into the supernatant stream containing 98% of the insulin precursor Economics Suppliers Over 53 companies in the US that sell centrifuges Centrifuge Solutions Inc (CSI) sell high speed disk centrifuges for applications in the food, chemical and pharmaceutical industries Alternatives