RCFUGE.SW-1.1 - Faculty of Medicine

advertisement

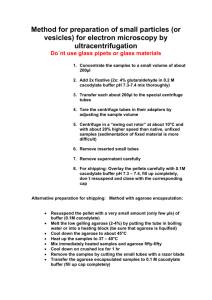

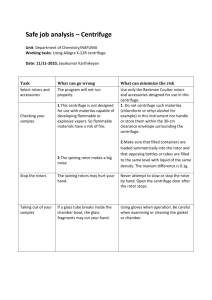

OHS026 Safe Work Procedure Faculty/Division Medicine Document number School/ Divisional Unit nephrology Initial Issue date 1.9.2010 RCFUGE.SW Current version 1.1 Current Version Issue date 10.1.2012 Next review date 10.1.2015 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Basic Operating Procedures for the High-speed Floor-mounted and Low-speed bench top centrifuges Title: Associated risk assessment title and location: : ___________________________________________________________________________________________________________ ___________ Page 1 of 7 Safe Work Procedure Date Effective: 10.1.2012 Uncontrolled document when printed Current Version: 10.1.2015 Describe the activity or process ___________________________________________________________________________________________________________ ___________ Page 2 of 7 Safe Work Procedure Date Effective: 10.1.2012 Uncontrolled document when printed Current Version: 10.1.2015 Background & Scope: There are a number of different centrifuges available: (1) Bench top micro-centrifuges (non-refrigerated), (2) Bench top low-speed centrifuges (refrigerated & non-refrigerated), (3) Floor-mounted ultra-centrifuge (refrigerated). The basic operating procedure for any centrifuge is similar, however certain procedures are unique to each model. This SOP outlines basic operating procedures/instructions that cover the different centrifuge types, as well as specific guidelines for some of them. For comprehensive operating procedures for any particular centrifuge, please consult the relevant user manual. General Centrifugation Procedures/Instructions: 1. Firstly, identify the appropriate centrifuge to use (see below). 2. Make sure you are familiar with how to use the centrifuge. If not, please read the relevant user manual and/or get someone familiar with the correct operating procedures to show you how to use it. 3. Make sure that the samples you wish to spin are contained within the appropriate centrifuge tubes/bottles. It is very important that you are familiar with both the chemical resistance and the maximum tolerated G-force rating of the tubes you wish to use (for example: 0.5 ml tubes have a maximum of 9000xg not 14,000xg and 50ml FalconTM tubes cannot be used in the floor-mounted centrifuges). Stressing polymers with an inappropriate chemical and/or an inappropriate speed could be disastrous (eg. polycarbonate tubes with solutions containing phenol will dissolve). ___________________________________________________________________________________________________________ ___________ Page 3 of 7 Safe Work Procedure Date Effective: 10.1.2012 Uncontrolled document when printed Current Version: 10.1.2015 4. Prepare balance tube(s) if required. Please note that volume is NOT the correct measure to use when different chemicals are used, or when the samples are to be centrifuged at high speed. Chemicals have different densities and will hence have different weights at the same volume. Therefore, when centrifuging at high speed (> 4000 rpm) and/or when using large volumes (>50 ml), accurately adjust the weight of your balance tubes to match that of your samples (correct to two decimal places). Note: Particular care is required when using the ultra centrifuge due to its high g/RCF capacity. Balance tubes are to match sample tubes to three decimal places for this centrifuge. 5. If using a swing bucket rotor, make sure that the rotor and the buckets are secure but able to move freely in their brackets (as per the specifications), and that you have selected the correct inserts/adaptors before commencing the run. NB. the Renal SW55TI swing out rotor is down rated to 35,000 rpm; use all 6 buckets in the correct positions with the correct caps correctly threaded. An important point to remember: A rotor accident as a result of an imbalance, WILL not only damage the centrifuge and destroy your samples, it may also result in serious operator injury. Remember that small differences in weight will be amplified at high speed! 1.0 gram at 60,000rpm is equal to 1000 kg or 1 tonne in the centrifuge tube. ___________________________________________________________________________________________________________ ___________ Page 4 of 7 Safe Work Procedure Date Effective: 10.1.2012 Uncontrolled document when printed Current Version: 10.1.2015 List all resources required including plant, chemicals, personal protective clothing and equipment, etc Correct tubes, balance, balancing tubes. List potential hazards and risk controls including specific precautions required Use of Ultracentrifuge. Imbalanced tubes can cause accident. Two main rules that must be followed; 1. Balance ultra-centrifuge tubes to at least the third decimal place weight using pan balance. 2. The vacuum should be turned off only after the rotor has come to a complete stop. 3. Tubes must be sealed against the vacuum; this means using the swing out rotor with screw on caps, or for the angle rotors, tubes with heat seals or special caps for each tube. List emergency shutdown instructions Contact supervisor or senior person in lab. Call emergency, try to alert all the people in the lab, secure area where accident has happened if you can and then leave premises ___________________________________________________________________________________________________________ ___________ Page 5 of 7 Safe Work Procedure Date Effective: 10.1.2012 Uncontrolled document when printed Current Version: 10.1.2015 List clean up and waste disposal requirements Follow Laboratory waste management Generally, treatment with 1% active chlorine (Bleach) for 30 minutes is adequate for liquid waste/spills. List legislation, standards and codes of practice used in the development of the SWP Guidelines for dealings with Genetically modified organisms in accordance with the gene technology legislation Section 4 Classification of laboratory practices and procedures (AS/NZS 2243.3:2002) Management of biological spills: Guidelines Version: 2 (section 5, AS/NZS 2243.3:2002) Appendix E: Chemical disinfectants (AS/NZS 2243.3:2002) Laboratory Cleaning. Section 8 (AS/NZS 2243.3:2002) Waste Disposal Section 9 (AS/NZS 2243.3:2002) Gene technology Procedure version 0.1, 01/11/2006 www.ogtr.gov.au/pubform/index/htm www.riskman.unsw.edu.au/ohs/genetech or (http://www.hr.unsw.edu.au/ohswc/ohswc_home.html) AS/NZ 2243.3:2002 Safety in Laboratories Section 4: classification of laboratories, practices and procedures. AS/NZ 2243.3:2002 Safety in Laboratories Section 6: general precautions and special equipment. Management of Biological Hazardous Spills or Accidental Release of Biological Agents (UNSW Draft v2, March 2001). AS/NZ 2243.3:2002 Safety in Laboratories Section 5: laboratory spills. AS/NZ 2243.3:2002 Safety in Laboratories Appendix E: chemical disinfectants. AS/NZ 2243.3:2002 Safety in Laboratories Section 8: laboratory cleaning. AS/NZ 2243.3:2002 Safety in Laboratories; Section 9: waste disposal ___________________________________________________________________________________________________________ ___________ Page 6 of 7 Safe Work Procedure Date Effective: 10.1.2012 Uncontrolled document when printed Current Version: 10.1.2015 Supervisory approval, training, and review Supervisor: Signature: Plant custodian: Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: SWP review date: Responsibility for SWP review: ___________________________________________________________________________________________________________ ___________ Page 7 of 7 Safe Work Procedure Date Effective: 10.1.2012 Uncontrolled document when printed Current Version: 10.1.2015