Safe Work Procedure - Faculty of Medicine

advertisement

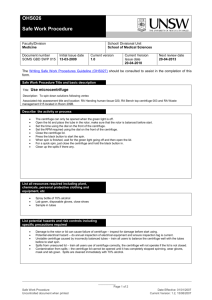

OHS026 Safe Work Procedure Faculty/Division Medicine Document number SOMS GBD SWP 020 School/ Divisional Unit School of Medical Sciences Initial Issue date 13-03-2009 Current version 1.0 Current Version Issue date 20-04-2010 Next review date 20-04-2013 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Protein extraction Title: Description: extract protein from human or animal tissue Associated risk assessment title and location: RA Handling of human tissue 020, RA Bench top centrifuge 003, RA Waste management 015 located in room 209B Describe the activity or process Weigh samples (100mg) and place it in 1ml protein extraction buffer in a special, GeneWorks homogenizer centrifuge tube. Homogenize the samples. Centrifuge the samples at 12000g for 15min at 4oC. Transfer the supernatant to a fresh tube. Measure protein quantitatively by spectrophotometer with Lowrys method. Add 200ml of the suspension or sample to the cuvette. Make up protein standards. Add 1ml of lowrys base solution to each cuvette, leave for 10min. Add 0.1ml of color solution to each cuvette, mix thoroughly, leave for 20min to develop the color. Read absorbance on the spectrophotometer at wavelength 750nm. Store protein samples at -80. List all resources required including plant, chemicals, personal protective clothing and equipment, etc Suitable PPE Protein extraction buffer, lowrys solution and standard BSA Centrifuge tubes, samples, scissors, forceps, 70% ethanol spray bottle Spectrophometer, homogenizer and centrifuge List potential hazards and risk controls including specific precautions required Chemicals may be hazardous – for chemicals check MSDS and wear PPE, all users are well trained and all spills are cleaned immediately and disposed in chemical waste. Tissue can be contaminated or infectious – training is required if handling human tissue, wear PPE, all spills are cleaned immediately with 70% ethanol and disposed in autoclaved waste. Scissors and spatula are wiped with 70% ethanol and washed with water. All weight boats and tubes are disposed in biological waste. Potential electrical hazard – do annual inspections of electrical equipment and ensure electrical safety tag is current. Potential aerosol hazard – wear PPE and use a biosafety hood or wear a mask if it is necessary. ___________________________________________________________________________________________________________ ___________ Page 1 of 2 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List emergency shutdown instructions Spectrophometer, homogenizer and centrifuge have “OFF” switch that can be used in emergency. Shut all electrical equipment off at power point in case of emergency. List clean up and waste disposal requirements For chemicals: Clean up with detergent and then with water Dispose into chemical waste For samples: Clean up or sock with 70% ethanol Dispose into biological waste or in autoclaved waste (human sample) List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Australia Dangerous Goods Code Code of Practice for the Labeling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects Australian Standard AS2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects. Australian Standard AS2243.7-1991. Safety in laboratories. Part 7: Electrical Aspects. AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance Safe Work Procedure Form (OHS026) UNSW Hazardous Waste Disposal Procedure Supervisory approval, training, and review Supervisor: Prof E Burcher Signature: Plant custodian: Signature List competency required – qualifications, certificates, licensing, training - e.g. course or instruction: SWP review date: 20-04-2013 Responsibility for SWP review: Fei Shang ___________________________________________________________________________________________________________ ___________ Page 2 of 2 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007