Construction of the heavy oil residue hydrocracking plant

advertisement

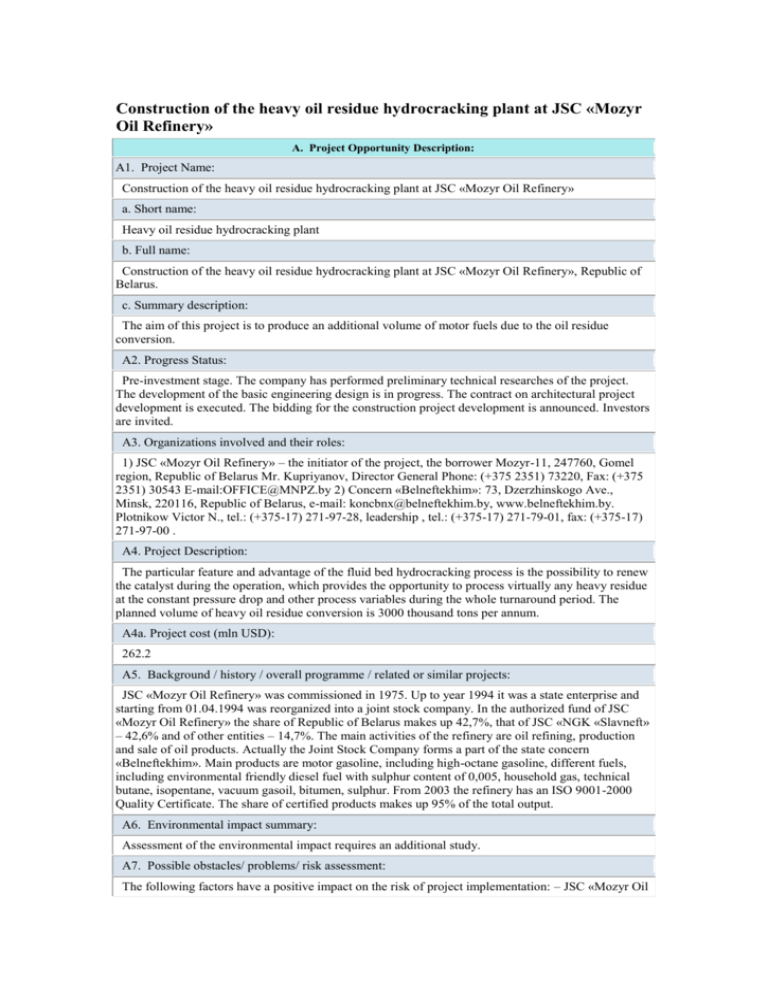

Construction of the heavy oil residue hydrocracking plant at JSC «Mozyr Oil Refinery» A. Project Opportunity Description: A1. Project Name: Construction of the heavy oil residue hydrocracking plant at JSC «Mozyr Oil Refinery» а. Short name: Heavy oil residue hydrocracking plant b. Full name: Construction of the heavy oil residue hydrocracking plant at JSC «Mozyr Oil Refinery», Republic of Belarus. c. Summary description: The aim of this project is to produce an additional volume of motor fuels due to the oil residue conversion. А2. Progress Status: Pre-investment stage. The company has performed preliminary technical researches of the project. The development of the basic engineering design is in progress. The contract on architectural project development is executed. The bidding for the construction project development is announced. Investors are invited. А3. Organizations involved and their roles: 1) JSC «Mozyr Oil Refinery» – the initiator of the project, the borrower Mozyr-11, 247760, Gomel region, Republic of Belarus Mr. Kupriyanov, Director General Phone: (+375 2351) 73220, Fax: (+375 2351) 30543 E-mail:OFFICE@MNPZ.by 2) Concern «Belneftekhim»: 73, Dzerzhinskogo Ave., Minsk, 220116, Republic of Belarus, e-mail: koncbnx@belneftekhim.by, www.belneftekhim.by. Plotnikow Victor N., tel.: (+375-17) 271-97-28, leadership , tel.: (+375-17) 271-79-01, fax: (+375-17) 271-97-00 . А4. Project Description: The particular feature and advantage of the fluid bed hydrocracking process is the possibility to renew the catalyst during the operation, which provides the opportunity to process virtually any heavy residue at the constant pressure drop and other process variables during the whole turnaround period. The planned volume of heavy oil residue conversion is 3000 thousand tons per annum. А4a. Project cost (mln USD): 262.2 A5. Background / history / overall programme / related or similar projects: JSC «Mozyr Oil Refinery» was commissioned in 1975. Up to year 1994 it was a state enterprise and starting from 01.04.1994 was reorganized into a joint stock company. In the authorized fund of JSC «Mozyr Oil Refinery» the share of Republic of Belarus makes up 42,7%, that of JSC «NGK «Slavneft» – 42,6% and of other entities – 14,7%. The main activities of the refinery are oil refining, production and sale of oil products. Actually the Joint Stock Company forms a part of the state concern «Belneftekhim». Main products are motor gasoline, including high-octane gasoline, different fuels, including environmental friendly diesel fuel with sulphur content of 0,005, household gas, technical butane, isopentane, vacuum gasoil, bitumen, sulphur. From 2003 the refinery has an ISO 9001-2000 Quality Certificate. The share of certified products makes up 95% of the total output. A6. Environmental impact summary: Assessment of the environmental impact requires an additional study. A7. Possible obstacles/ problems/ risk assessment: The following factors have a positive impact on the risk of project implementation: – JSC «Mozyr Oil Refinery» is sufficiently stable financially and has a good credit history. – The principal crude-oil supplier is JSC «NGK «Slavneft», which is a shareholder of the refinery. Besides, the alternative crude oil suppliers are elaborated. – Guaranteed sales of products both in the foreign and domestic markets. A8. Term of realization / term of recoupment (years): 4/A9. Project’s branch: Chemical and petrochemical industry B. Capital Cost Items (additional requirements for project): B1. Project physical components B2. Capital cost (mln USD) Design and engineering 13.6 Purchase of equipment and materials 127.2 Building and assembly works 103.5 Costs for common facilities construction 17.9 Total: 262.2 C. Capital Resources Available from Sponsors/ Proposers: C1. Resources 'in kind', grants, investments, equity / ownership, etc. Internal funds C2. Amount (mln USD) 212.2 D. Required Financial Assistance: D1. Financing gaps, type of financial assistance required: Crediting D2. Sources of finance Foreign investment funds D3. Type of investment D4. Amount (mln USD) Credit, direct investments 50.0 D5. Financial/ International Institution Name: E. Demand (users) and revenues: E1. Type of users/ markets, volumes, pricing, revenues, quantifiable benefits/ savings: The products planned under the project: low-sulphur heating fuel according to ISO 8217, increase in the gasoline production by 200 mln. tons per year, increase in diesel fuel production according to Euro 5 by 1 mln. tons per year. E2. Revenues (Sales) E3. Amount (mln USD) Proceeds from the products sales considering customs fees. 594.9 F. Operating and Maintenance Costs: F1. Cost components, strategies for cost recovery, operating organisations, subsidies, etc.: The refinery has engineering services and energy sources required for the production. Additional allotment of land is not required. F2. Cost Item F3. Amount (mln USD) Feedstock and materials 551.0 Process power resources 4.5 Personnel costs 0.5 Amortization 11.4 TOTAL 567.4 G. Net Income Value: G1. Net Income Value G2. Amount (mln USD) Net profit 27.5 H. Project information source: H1. This form was completed by: Mr. Leshnevsky - the director of management on reconstruction and development of JSC «Mozyr Oil Refinery» H2. Organisation (address): JSC «Mozyr Oil Refinery» Mozyr-11, 247760, Gomel region, Republic of Belarus. H3. Тel/Fax/E-mail: Phone/fax: (+375 2351) 74630, E-mail:OFFICE@MNPZ.by H4. Date: December, 2007 H5. Supreme Organization: Concern «Belneftekhim»