The Impact of high ethanol winemaking on phenolics

advertisement

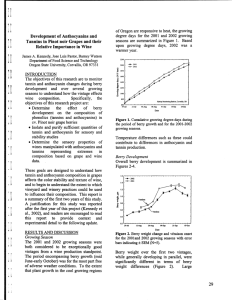

Wine Flavor 101: The Impact of High Ethanol, Saignée and Extended Maceration on Wine Phenolic Composition Jim Harbertson Associate Professor Washington State University INTRODUCTION • INTRODUCTION – Color – Tannins – Polymeric pigments • TRENDS IN VITICULTURE/WINEMAKING – Saignée – Alcohol • EXPERIMENTAL DATA • ASSESMENT • FUTURE DIRECTIONS Phenolics-why we care • Several Classes • Contribute Sensory Characteristics of Wine • Color- Anthocyanins and co-factors • Astringency – Tannins and LPP • Bitterness - Catechins • Anti-oxidant Capacity- All phenolics especially those with ortho configuration. Anthocyanins • pH Dependent • Copigmentation – Self-association – Co-Factors • Color Change – Hyper chromic shift (more color) – Bathochromic shift (blue color) • Ethanol? – Disrupt association – Bathochromic shift – Partitioning of flavonols? • Water? – Disruption, dilution Seed Tannins • Very Abundant – 3-5 mg/berry – Amount per seed does not vary much • Decline During Ripening • Average Length – 10 sub-units • Astringent • Gallic Acid Ester – Alters protein ppt. • Winemakers usually avoid seed tannins Skin Tannins • Not so abundant – 0.5 -0.9 mg/berry • Ripening: No specific pattern • Average Length – 32 sub-units • Astringent • Unique sub-unit • Winemakers want skin tannins Polymeric Pigments • Wine Artifact • Mixture – Anthocyanins+ (tannins, ketoacids, cinnamates, etc.) • More resistant to Sulfur dioxide • Less pH sensitive • Color: brick-red 0.7 Rate of Extraction Graphic 4.5 4 0.6 Abs @520nm 0.5 3 0.4 2.5 0.3 2 1.5 0.2 1 0.1 Anthocyanins AU@520nm Tannins (g/L) 0 0.5 0 0 10 20 30 40 50 Days of Skin/Seed Contact REDRAWN FROM RIBÉREAU-GAYON 1970 Tannins (g/L) 3.5 Skin and Seed Tannin Extraction • Pinot noir • Miniature (3L) • Skin Tannin Extraction Fast and Plateaus • Seed Tannin Extraction Slow but Linear Increase Demonstrated Redrawn from Calderon and Kennedy 2008 Polymeric Pigment Formation 3.50 Absorbance @ 520 nm 3.00 2.50 2.00 1.50 1.00 0.50 0.00 Day 1 Press Barrel ENHANCING PHENOLICS: TRENDS VITICULTURE • VITICULTURE – SMALL BERRIES ARE DESIRED • CLONAL SELECTION, SITE SELECTION • EXTENDED MATURATION – SEED MATURATION – REMEMBER BERRY SHRINKS! – IRRIGATION • EARLY STRESS, MORE TANNIC FRUIT – LOCATION • EXAMPLES AVAILBLE THE TREND in WA, CA? • Cab Family Fruit – Want Brown Seeds, Less green aromas – Result: High Brix – Result: High pH—more K+, lower Malic • Resulting Wine – – – – – High Ethanol High pH, Low TA Big Extraction Lots of color, plenty of tannins Astringency is muted by ethanol, acidity How are tannins influenced by ethanol? • Higher ethanol extracts more tannins? – Consensus says more “bad” seed tannins • Bitterness? – Catechins are more bitter with more [EtOH] • Astringency? – Thought that ethanol lowers astringency by making protein-tannin complexes soluble – So more tannins but less “tannic?” Hang Time Fruit Trend-2 • Small Berries with 25 Brix and above – Increase Skin/Seed: Juice – Problem: Water back necessary to avoid stuck ferment – How to keep skin/seed: juice from hang time fruit? • Answer: Water back and Saignée at the same rate. – Sounds simple enough, right? Complicated • Wait overnight for dried fruit to rehydrate • Take Brix Measure, Determine total volume of tank – Convert all values to metric it is way easier! • Calculate % of water to achieve target Brix • Bleed that percentage of juice • To calculate the amount of water to achieve target Brix you must subtract amount bled off from total first. • So the amount you bleed is greater than what you add back. Math involved • • • • • M1V1=M2V2 [Brix]V1=[Brix]V2 Brix = g/100 mL Convert Tank volumes to L Or you could convert Brix into pounds of sugar per gallon. • Ewww. Calculate the Run-off Tank #1 Metric Target Metric 1569.6 gallons 5940.9 L 1569.6 +X 5940.9 +X 28.4 Brix 284 g/L 24.1 Brix 241 g/L 5940.9L ´ 284g 241g = ´ (x + 5940.9L) L L (1687225.8 -1431765.6) = xL 241 gallons xL ´ = x gallons 3.785L X=1060.0 L or 280 gallons So you bleed off 1060.L or 280 gallons for a total of 4840.9 L or 1289.6 gallons Now for the water addition Tank #1 Metric Target Metric 1289.4 gallons 4880.9 L 1569.6 +X 4940.9 +X 28.4 Brix 284 g/L 24.1 Brix 241 g/L 4880.9L ´ 284g 241g = ´ (x + 4880.9L) L L (1386175.3 -1176296.7) = xL 241 gallons xL ´ = x gallons 3.785L x=870.9 L or 230 gallons Experiment: High Ethanol Water Addition (%) Volume Change (%) Initial Brix Brix at Inoculati on 0 18.7 ±0.6 +18.7 28.3 ±0.2 24.3 ±0.9 High Ethanol 0 4.5 ±0.8 +4.5 28.0 ±0.2 26.8 ±0.6 Low Saignée 18.1 ±1.2 18.1 ±0.2 0 28.1 ±0.3 24.1 ±0.4 Low Saignée EM 16.8 ±0.4 16.8 ±0.4 0 27.8 ±0.1 24.2 ±0.2 High Saignée 32.7 ±1.7 16.4 ±0.8 -16.4 27.7 ±0.2 24.2 ±0.8 Treatme nt Juice Removal Control 10 ton Scale Duplicates Merlot Columbia Valley pH 3.9 TA 0.33 g/100mL Winemaking Details • • • • • • Mechanical harvest-Yield 170 gallon/ton 30 ppm SO2 at destemming YAN adjusted to 225 ppm with DAP Yeast Strain “Premier Cuvee”-S. cerevisiae bayanus Mix after water/SO2 1 minute per ton Pump-overs 1 minute per ton 3 times a day – Until drain and press (~ 8.5 minutes) • Drained to Tank- Press Fractions Recombined-finish primary in tank • Sent to Barrel to undergo ML • Sensory on wines 1 year after crush Columbia Basin Vineyard •Merlot BIG CANOPY CLONE 3 9 year old 5 TON/ACRE •Read Veggie to the point nobody likes it! •Row 73-74 •VINEYARD SIZE •Row 81-82 Sampled•Row Rows89-90 •20 acre~8 hectare •Row 97-98 •16 REPLICATES •Row 9-10 •Row 105-106 •Row 17-18 •SAMPLE SIZE •Row 113-114 •Row 25-26 • 15 clusters per rep •Row 121-122 •Row 33-34 •Row 129-130 •Evenly spaced across vineyard •Row 41-42 •Row 49-50 •Fruit from alternate sides of canopy •Row 57-58 •15 Clusters dissected into berries •Row 65-66 •30 Berries per replicate for tannins •Harvest date Oct 12-13 •Harvest Data 28 Brix 0.33 g/100mL TA pH 3.9 •Tannin by protein ppt Data STD ERROR Treatments AVE STDEV Berry weight (g) 1.18 0.073 0.018~1.5% 1.06-1.26 16 Seed number per berry 1.68 0.115 0.029~1.7% 1.53-1.87 16 Skin Tannin mg per berry 0.78 0.094 0.024~3.0% 0.53-0.91 16 Seed Tannin mg per berry 3.30 0.223 0.056~1.7% 2.89-3.65 16 1 2 3 4 3.45 mg/g FW ~ 3450 mg/L wine potential 19 % Skin Tannin 81% Seed Tannin Berry Weight Variability less than fruit tannin Overall variability similar RANGE N Basic Wine Chem Treatments pH TA EtOH % Control 3.81 ±0.02 0.50 ±0.05 14.0 ±0.31 High Alcohol 3.89 ±0.04 0.52 ±0.03 15.9 ±0.16 Low Saignée 3.86 ±0.03 0.52 ±0.03 13.8±0.23 High Saignée Extended Maceration 3.81 ±0.04 0.51 ±0.03 3.84 ±0.04 0.50 ±0.02 13.8±0.13 14.2 ±0.33 Anthocyanins- Anthocyanins-Low Saignée Anthocyanins-High Saignée Anthocyanins-High Ethanol Anthocyanins-Low Saignée Ex Mac. Anthocyanins-All Muddled Tannin Extraction Anthocyanin, tannin and iron reactive phenolics at press and 185 days Anthocyanins (mg/L) Tannins (mg/L) Fe Phenolics (mg/L) TREATMENT PRESS 185 Days PRESS 185 Days PRESS 185 Days Control 468 C 418 C 469 B 399 D 1145 D 1338 D High Ethanol 656 B 401 C 577 B 512 C 1338 C 1578 C Low Saignée 687 B 461 B 549 B 500 C 1300 CD 1291 D Low SaignéeEM 528 B 352 D 985 A 980 A 2026 A 2353 A High Saignée 750 A 558 A 686 B 658 B 1690 B 1783 B Letters within a column indicate significant differences at p<0.05 Error bars excluded for space. mg skin tannins per g FW mg seed tannins per g FW % Skin Tannins Extracted % Seed Tannins Extracted Wine Proportion Skin Wine Proportion Seed 0.66 A 3.29 A NA NA NA NA 0.36 B 2.77 B 46% 16% 42% 58% 0.40 B 2.45 B 40% 25% 26% 74% 0.36 B 2.74 B 45% 17% 40% 60% Low Saignée-EM 0.31 B 1.83 C 53% 44% 21% 79% High Saignée 0.44 B 2.54 B 33% 22% 27% 73% Treatment Harvest Fruit Control High Ethanol Low Saignée Polymeric Pigments Polymeric Pigments Treatment Effect Sensory Courtesy of Dr. Carolyn Ross WSU PULLMAN Principle Components Analysis Assessment • Saignée at the same rate as water back – No effect on phenolics – No effect on sensory – Complicated – Time Consuming – Potentially Wasteful Assessment • Want more Color or More Tannins? – High Saignée • More anthocyanins, tannins, more SPP – Extended Maceration • More tannins, more LPP • Sensory: Can be more drying Assessment • Higher Ethanol Wine – More Tannins – Not less astringent than control with large increase in EtOH – More Seed Tannin Extraction – Some Color enhancement – Hot Description – Less Fruit Flavor! • Solubility of aromas in alcohol found in other work – Trending towards less smooth, more dry but more dynamic ~ stats indicate not significant – Is it worth it? – Dilution is the solution? – Greater Volume, lower taxes Acknowledgments • • • • • Linda Bisson UC Davis Chateau Ste. Michelle Winemaking: Josh Maloney, Bob Bertheau Sensory: Carolyn Ross, Karen Weller Family: Eileen and Andrew Harbertson Vineyard Data By Row Based on variation across vineyard the winemaking reps should be consistent. No ability to separate rows because of mechanized harvest. Vineyard Data By Row Based on variation across vineyard the winemaking reps should be consistent. No ability to separate rows because of mechanized harvest. Tannin/seed vs. seeds per berry Shows that berries with fewer seeds seem to compensate. No relationship between seed tannin/berry and seeds per berry. Good relationship (r=0.81) seed weight and berry weight