NNS Facilities Contractor Business Review Meeting

advertisement

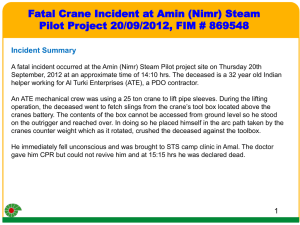

1st Quarter Contractor Business Meeting Facilities Session March 8, 2013 Mike Kehoe & Yesika Castro-Hernandez Plant Engineering Agenda Lift Plans Crane Envelope Requirements Securing Material During High Winds Excavation GIMMS Map Unknown Utilities Excavation Inside Buildings Hand Rail Requirements Background Checks Waste & Scrap Disposal Plan 2 Lift Plans Load weight at boom length and angle. Include weight of lifting gear. Specify lead rigger. Ensure communication methods are established. Determine the location of the load’s center of gravity. Always perform a second check prior to lifting equipment/material. Strongly urged to perform lifts under 75% crane capacity. Lifts above 75% capacity are considered critical lifts. 3 Lift Plans Specify all gear capacity. Check gear before every use. Current Inspection tag within inspection date. Surface cracks, cuts, or gouges. Evidence of heat damage. Excessive wear. Core protrusion in straight runs. Severe kinking or crushing. Any sign of possible damage Decrease lifting gear capacity at determined angle. Risk Assessment Pinch Points Weather conditions Limited Visibility Travel path of load Landing site 4 Typical Crane Observations • Improper Rigging – Using damaged slings – Using handling equipment improperly – Lifting unbalanced loads – Point loading hooks • No or Inadequate Lift Plans – Failure to have a lift plan on the job site – Failure to provide complete details and/or process to make a successful lift on a lift plan. – Inadequate risk assessment and mitigation • Travel Path – Parking vehicles in yellow travel path – Leaving material in yellow travel path 5 • Operator Error – Removed Anti Two-Blocking Device – Side loaded crane boom – Not setting outriggers properly – Operating with damaged running rope – Talking on cell phone while operating crane – No operators daily check list (ODCL) performed • Working Under/On Load – Passing loads over people’s head – Allowing personnel to work on or under a suspended load Lifting & Handling Highlight - Crane Envelope Requirements • SOP O40-2.3, FACILITIES & WATERFRONT SUPPORT PROJECT DESIGN PROCESS • (4)(j) – – Sensitive Work Area – A work area that requires special consideration above and beyond a typical work site due to the potential to disrupt critical operations or which requires special permission to perform work on or in. Examples include but are not limited to: Computer Data Center, RadCon Controlled Areas, SWMU (Solid Waste Management Areas), Security Features, Crane Envelopes, Government Owned and Operated Facilities (SGCC, NRRO), Certified Dry Dock Facilities, Certified Railroad Tracks, etc • (6)(a)(23) – – Facility modifications in or near a crane envelope merit special attention. Comply with Figure 2 to ensure design avoids fouls with the crane envelope. 6 Lifting & Handling Highlight - Crane Envelope Requirements SOP O40-2.3, Figure 2 (1 of 2): 7 Lifting & Handling Highlight - Crane Envelope Requirements SOP O40-2.3, Figure 2 (2 of 2): 8 Lifting & Handling Highlight - Crane Envelope Requirements • SOP O40-2.6, FACILITIES & WATERFRONT SUPPORT PROJECT START-UP & COMMISSIONING PROCESS • (4)(d)(1) – – Develop Pre-start Checklist (CxD-1) – Create a customized list of conditions, parameters, readings, settings, etc. that are important or required to verify before the equipment is initially started. Refer to equipment manuals and similar installations for these items. Examples of pre-start checks are fluid levels, motor rotation, PLC I/O checks, leveling, torque values, insulation resistance, voltage, etc. If applicable, the Commissioning Engineer shall ensure that the Work Authorizing Document (SAP Notification), has been completed and signed off by the Crane Audit group for work that encroaches within the crane’s envelope. (See Reference b – FWS Design Process SOP for Facilities Modification and/or Repairs in or Near the Crane Envelope flow chart and details.) • Reference (b) is SOP O40-2.3 9 Securing Material During High Winds Be aware of high wind advisories. Ensure that light items are secured to heavy permanent structures. Bundle items together if possible. Remove any trash or refuse from job site as often as possible. Construction sites must be left secured and in orderly fashion when unattended. 10 Excavation Excavation Permit GIMMS Map supplied by coordinator. The GIMMS System and its maps are a work in progress and constantly updated. Currently displays mechanical utilities with the best information available at the time. This year the GIMS team will add 30 psig steam and high voltage. The GIMMS System needs your support for growth and accuracy. GIMMS map to be kept with dig permit form on job site. Unknown Utilities Contact coordinator immediately. Coordinator to contact Water Tender and/or Emergency Electrician. Determining if a utility is abandoned, or active is the responsibility of the coordinator and the utility system owner. 11 Performing any modifications to utilities found during excavation must be approved by the coordinator and the utility system owner. Excavation • Drilling inside buildings: – Drilling performed into building floors and walls where possible utility damage could occur: • Floor or Wall scan- Check for rebar, mechanical, and electrical utilities. • Determine if an enclosure 3 of RCWP V-15 is necessary when performing work in a nuclear or radiological building. Contact your coordinator. 12 Images taken from: www.dismartofmaine.com Excavation • Any excavation must be barricaded, fenced or otherwise protected against accidental entry by pedestrians. • OSHA 29 CFR – 1926.651(c)(2) • Means of egress from trench excavations. A stairway, ladder, ramp or other safe means of egress shall be located in trench excavation that are 4 feet or more in depth so as to require no more than 25 feet of lateral travel for employees. 13 Hand Rail Requirements Around Openings • A brace must be installed on every corner. • Cable must be taut and secured with two clamps. • Hand rail: – Top rail 42” minimum – 45” maximum height. – Middle rail must be 21” bellow top rail. – 48” Minimum – 8’ maximum spacing between braces – Top rail must withstand a force of 200lbs. • OSHA 1910.23(e)(3)(i) 1910.23(e)(3)(v)(c) 14 Background Checks • 15 Time Frames – A background investigation is required for all unescorted badge visitors every three (3) years in order to re-verify criminal and DMV checks – A new background investigation is required should the individual change employers or have a break in service lasting 90 days or more. Waste & Scrap Disposal Plan • Each project will have a waste and scrap disposal plan. – Dumpsters, excavated soil storage area, storage containers, etc. • NNS recycled materials. – O46 approval must be obtained before any asphalt or concrete is sent to the north yard recycling bins. – Contact O46 Rich Giunti (757) 880-3549. • Each project coordinator and contractor foreman must develop a recycle plan. – The plan must include: • Temporary secure storage to avoid pilferage. – High-value scrap (stainless steel pipe, copper pipe, copper or aluminum wire, lead coated copper cable, etc.) shall be removed to the scrap yard at the end of each day or secured in a storage container. • A path to the NNS recycle system when appropriate (i.e., scrap yard). 16 QUESTIONS???? • If you have questions regarding this presentation, please contact your Contract Coordinator or: Yesika Castro-Hernandez O41 – Plant Engineering 757-353-2772 Yesika.L.CastroHernandez@hii-nns.com 17