anderson separator product line overview

advertisement

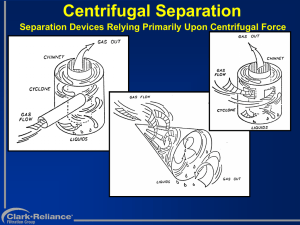

ANDERSON SEPARATOR™ ENGINEERED PRODUCTS Product Overview Filtration Group Overview & Qualification Package National Filtration Engineered Systems Anderson Separators Gas / Liquid - Solids Jerguson Gage & Valve Level Gages Reliance Boiler Trim HYCOA Liquid Filtration Jacoby – Tarbox Sight Flow Indicators Magne-Sonics External Level Switches Clark-Reliance Filter Elements Clark Steam and Drain Traps Corporate History 1884 - Reliance Gauge Column Company produces first ever alarm water column for boiler operators 1908 - Clark Manufacturing Company founded: steam traps, & strainers 1962 - Clark Manufacturing acquired by Cleveland industrialist 1963 - Clark Mfg. and Reliance Gauge Column merge forming The Clark-Reliance Company 1982 - Clark-Reliance purchases Anderson Steam Trap 1986 - Anderson’s line of separators and purifiers purchased 1986 - Jacoby-Tarbox (est. 1914) acquired 1986 - Jerguson Gage & Valve (est. 1905) acquired 1988 - World Class Manufacturing Facility Built (Ohio, USA) 1992 - ISO-9001 Certification 1993 - Jacoby-Tarbox’s line of eductors added 1999 - Magne-Sonics acquired 1999 - Purchased Mueller Steam Separator product line 2000 - National Filtration Systems purchased 2003 - HYCOA (Hydralic Company of America) purchased Strongsville Manufacturing Facility & Corporate Head Quarters Plant Data Manufacturing Plant: 60,000 Square feet Office: 12,000 Square feet Resource Availability and Personnel • Clark-Reliance maintains a staff based on JIT(Just in Time) scheduling. Our Plant capacity is scheduled and running at 65% (single shift) for 2004 • Clark-Reliance employs in excess of 200 people worldwide – Management 15 Supervisory 15 – Engineering, Drafting Project Management, and Purchasing 20 – Welders, Fitters, Machinist, and Assembly 100 – Other 50 Engineering & Project Management • Major projects are assigned a specific project manager and are scheduled using Microsoft Project scheduling software • All drawings are completed in AutoCad or Solid Works CAD software. Our engineering group has the capability to send and receive all drawing packages and specifications electronically Banking & Financials • Clark-Reliance Corporation sales turnover is in excess of $50MM USD. • Clark-Reliance Corporation is a closely held private corporation. Detailed financial information is not released without an executed confidentiality agreement. • Clark-Reliance’s banking is transacted through: – National City Bank – Cleveland, OH Quality Certifications Quality Assurance policies and procedures are in place for Clark-Reliance’s entire line of products. Non-coded as well as ASME code procedures assure our customers’ final products will meet the specifications Quality procedures are in place to manufacture to the following quality standards: ASME Section VIII – U & R DNV PED / CE ABS ATEX ASME/ANSI 31.1 & 31.3 ISO 9001 – 2000 Partial Users List Bechtel Utility Engineers Parsons Flour Daniel General Electric Power Systems Burns & McDonnell Siemens Westinghouse Power Systems Shaw/Stone & Webster SMOE Williams Gas Pipe Line El Paso Energy Bibb & Associates Kinder Morgan Lyondell Petrochemical El Paso BP Washington Group Exxon Mobile Partial Users List El Paso Tennessee Gas Pipeline Peter Brotherhood Black & Veatch Calpine Rolls Royce FPL Alstom Jacobs Nooter/Eriksen Duke Southern Companies PTT Southern Natural Gas SNC-Lavalin Aker-Kvaener Bantrel Alliance Engineering Siemens-Westinghouse Engineered Equipment • Gas/Liquid • Gas Solid • Liquid/Solids Engineered Systems • Project Management • Pre-assembled Systems • Modular Skid Systems Filtration Services • Liquid Filter Elements • Air/Gas Filter Elements • Coalescing Filter Elements • Micron Ratings from 0.3 µm • Custom Sizes Methods of Gas / Liquid Separation • Centrifugal/Multi-Cyclone • Vane • Filter/Coalescer Centrifugal Separation Separation Devices Relying Primarily Upon Centrifugal Force Vane Separation Separation Devices Relying Primarily Upon Impingement Filter/Coalescer Separation Separation Devices Relying Primarily Upon Filtration Packed Granulated Filter Media Expected Efficiencies of Separation Methods METHOD Centrifugal/Multi-Cyclone Vanes Filter/Coalescer EFFICIENIES 10 Micron 3 – 8 Micron 0.3 Micron What is a Micron? 25.4 mm 25,400 MICRONS 1 MICRON .000039 INCH LOWEST LIMIT OF VISIBILITY (NAKED EYE) 40 MICRONS MICROSCOPIC 0.2 uM TO 40 uM ULTRA-MICROSCOPIC .001 uM to 0.2 uM Ultra Microscopic Microscopic Normal Eyesight Quiet Atmosphere Disturbed Atmosphere Tobacco Smoke FOG Rain Drop MIST Sea Salt N H4Cl Fumes Oil Smoke Virus & Protein Bacteria Dust Causing Lung Damage H2 SO4 Mist Rosin Smoke Carbon Black Sulfied Ore Spray-Dried Milk Pollens Ground Limestone Stoker Fly Ash SO3 Mist Pigments Oil Smoke Zinc Oxide Fumes Pulverized Coal Alkali Fumes Metallurgical Fumes Pulverized Coal Fly Ash Foundry Dust Cement Dust Metallurgical Dust Silica Streptococcus Pyogenes Talc Human Hair Blood Corpuscle AVGS – Vane Separator AMCS – Vane Separator ACF - Coalescing Filter .001 .01 0.1 0.3 1.0 8.0 5.0 10 100 1000 Microns Efficiency What do People Mean? - Percent Removal Rate i.e.. 99%, 99.5%, 100% - Total Removed by Count % Of Total Particles Of A Certain Range or Minimum Size. i.e. 99% of all particles 10 microns and larger. i.e. 100% of all liquid particles 8 microns and larger, and 100% of all solid particles 8 microns and larger. Anderson’s Centrifugal/ Multi-Cyclone Separators • AMCS - Multi-Cyclone Separator • Handles Heavy Solid Loadings • 100% of 8 and Larger Liquid Particles • 100% of 5 and Larger Solid Particles • 99% of 5 to 8 and Larger Liquid Particles AMCS Multi-Cyclone Centrifugal Separator • Nested Multi-Cyclone Elements. • Excellent For Dry Only, Low Maintenance • Efficiency: 100% of 5 Solids, 100% of 8 Liquids. • Versus HI-EF Centrifugal: More Efficient But Higher P (2-3 PSID OVERALL) • Basic Design No Slugging, MAX 5% Liquid/Solids by Weight • High Liquid Capacity Models Available AMCS Multi-Cyclone Centrifugal Separator AMCS Multi-Cyclone Centrifugal Separator Anderson’s Vane Type Separators • AVS - Inline vane Separator • AVGS - Vertical Gas Separator •100 % Removal of 8 Micron Liquid Particles • Pocketed Vane Design Vane Designs GEN 1. AKA “CHEVRONS” - Now Used as Coalescer GEN 2. “HOOK TYPE”- Greater Liquid Retention GEN 3.- “HOOK 2”- Even Greater Liquid Retention- Higher P GEN. 4- “POCKET VANE” CURRENT ANDERSON DESIGN • Lowest P of 2,3,&4. • Highest Liquid Removal • Most Efficient Separation /FT^2 = SMALLER DIAMETER SEPARATORS Vane Performance • Standard Efficiency is 100% of 8 > Liquids only • Some Solids Entrained with Liquid OKConsult Factory • Addition of a Coalescing Mesh Pad Increases Efficiencies to 100% of 3 > • TURNDOWN IS EXCELLENT: Down to 10% of Design Flow in Every Case AVS Type In-Line Separators • Custom Designed Per Application • 100% of 8 Liquid • Limited Solids - Pockets Can Plug • Turndown ratio is 10 - 110% of Design Flow • Vanes are 316 L SS Construction Standard • Removable Vane Design Available • Increase to 100% of 3 With Mesh or Vane Coalesce • Ideal For All Gas Processes • No Slugging- 5% Maximum by Weight of Entrainment TOP VIEW Anderson’s Filter Type Separators • AFS - Filter Separator -Filters used in combination with one other method • 100% of 3 and Larger Liquid and Solid Particles • 99% of .5 to 3 Solid Particles AFS Filter / Separator • Multiple Stages (Impingement-Filtration-CoalescingImpingement) No Slugging • High Efficiency- 100% Liquids & Solids 3 • 99% of Solids 0.5 to 3 • Horizontal or Vertical Designs • Different Separation Elements Available AFS Filter / Separator Anderson’s Coalescing Type Separators - Cont. • ACF - Coalesce Filter Separator -Filters and / or one other method • 99.98% of .3 Solid Particles and Aerosol Mist ACF Coalescing Filter Separator • Gas Polishing Coalescing Filter • Extra High Efficiency: 99.98% of 0.3 • Solids and Liquids • Filters are Expensive: Usually Want To Precede With Liquid / Solid Separator, OR: • Knockout Baffle in Lower Chamber , HI-EF, Vane, Or Multi-Cyclone to do Bulk Liquid Cleanup. - Extends Life Filters • Applications Include Gas Turbine Inlet, Oil Removal From Compressor Outlets ACF Coalescing Filter Separator Required Information • The Big Picture • Gas • Flow Rate • Removal of What? • Slugging / High Solids • Required Removal Efficiency • Minimum / Maximum Operating Pressure • Minimum / Maximum Operating Temp. Required Information • Pressure Drop • Arrangement • Connections • Materials • ASME Code Information Instrumentation Gage Glass Liquid Level Controller Liquid Level Switches Dump Valves Pressure / Temp. Gauges Relief Valves P Indicators and Transmitters Conclusion • Separators are critical pieces of equipment for the smooth operation of most all processes. • Different applications require different approaches, different styles of separators, and sometimes units in combination. • IT IS IMPORTANT TO GET ALL THE INFORMATION CORRECT THE FIRST TIME-- SAVES TIME AND $$ More Than Just A Separator. . . Systems Design & Integration Filtration Services Equipment Design & Manufacturing ® ®