anderson separator product line overview

advertisement

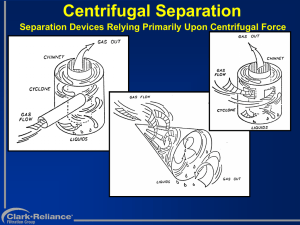

ANDERSON SEPARATOR™ ENGINEERED PRODUCTS Product Overview Engineered Equipment • Gas/Liquid • Gas Solid • Liquid/Solids Engineered Systems • Project Management • Pre-assembled Systems • Modular Skid Systems Filtration Services • Liquid Filter Elements • Air/Gas Filter Elements • Coalescing Filter Elements • Micron Ratings from 0.3 µm • Custom Sizes Methods of Gas / Liquid Separation • Gravity • Centrifugal • Demister Pad • Vanes • Filter Coalescer Gravity Separation • Slow the gas down allowing droplets and particles to fall out • Practical limits to this process 3X X Drain Gravity Separation Other Separation Devices Relying Primarily Upon Gravity Settling Centrifugal Separation Separation Devices Relying Primarily Upon Centrifugal Force Demister Separation Vane Separation Separation Devices Relying Primarily Upon Impingement Filter Separation Separation Devices Relying Primarily Upon Filtration Packed Granulated Filter Media Expected Efficiencies of Separation Methods METHOD EFFICIENIES Gravity 20 – 100 Microns Centrifugal 10 Micron Demister Pad 3 –10 Micron Vanes 3 – 8 Micron Filter Coalescer 0.3 Micron What is a Micron? 25.4 mm 25,400 MICRONS 1 MICRON .000039 INCH LOWEST LIMIT OF VISIBILITY (NAKED EYE) 40 MICRONS MICROSCOPIC 0.2 uM TO 40 uM ULTRA-MICROSCOPIC .001 uM to 0.2 uM Micron Basics -SIZE COMPARISON TABLES US SIEVE # 50 70 100 140 200 270 325 400 MESH/INCH 52 72 101 143 200 270 323 --INCHES 1.0 0.0394 1/64 0.0000394 OPEN- INCH .0117 .0083 .0059 .0041 .0029 .0021 .0017 .0015 MILLIMETERS 25.4 1.0 -.001 OPEN-MICRON 297 210 149 105 74 53 44 37 MICRONS 25,400 1,000 400 1.0 Ultra Microscopic Microscopic Normal Eyesight Quiet Atmosphere Disturbed Atmosphere Tobacco Smoke FOG Rain Drop MIST Sea Salt N H4Cl Fumes Oil Smoke Virus & Protein Bacteria Dust Causing Lung Damage H2 SO4 Mist Rosin Smoke Carbon Black Sulfied Ore Spray-Dried Milk Pollens Ground Limestone Stoker Fly Ash SO3 Mist Pigments Oil Smoke Zinc Oxide Fumes Pulverized Coal Alkali Fumes Metallurgical Fumes Pulverized Coal Fly Ash Foundry Dust Cement Dust Metallurgical Dust Silica Streptococcus Pyogenes Talc Human Hair Blood Corpuscle Cyclone Separators ANDERSON Hi-EF AMCS - Multi-Cyclone AFS - Filter Separator ACF - Coalescing Filter .001 .01 0.1 0.3 1.0 3.0 5.0 10 100 1000 Microns Efficiency What do People Mean? - Percent Removal Rate i.e.. 99%, 99.5%, 100% - Total Removed by Count % Of Total Particles Of A Certain Range or Minimum Size. i.e. 99% of all particles 10 microns and larger. i.e. 100% of all liquid particles 8 microns and larger, and 100% of all solid particles 8 microns and larger. Anderson’s Separation Methods All Mechanical • Gravity • Centrifugal • Impingement • Filtering General Applications • Gas Processing • Compressed Air • Industrial Markets • Power Generation Natural Gas Processing Applications • • • • • • • • OIL/GAS WELL HEAD GAS CONDITIONING TRANSMISSION STATIONS DISTRIBUTION STATIONS/CITY GATE COMPRESSOR STATIONS METERING STATIONS OFF-SHORE PRODUCTION TURBINE & COMPRESSOR PACKAGERS Compressed Air Applications • COMPRESSOR OEMs • AFTERCOOLER-EXCHANGER OEMs • AIR DRYING • INDUSTRIAL USE • PLANT MAINTENANCE Industrial Applications • Petrochemical - Refining - Chemical Production - Polymer Production • Steel Mills • Pulp and Paper Production • Refrigeration Power Generation Applications • Fuel Gas Conditioning • Internal Steam Drum Separators - HRSG • Steam Turbine - Combined Cycle • Air Atomization Anderson’s Vane Type Separators • AVS - Inline vane Separator • AVGS - Vertical Gas Separator • AVB - Internal Boiler Drum Separator • 100 % Removal of 8 Micron Liquid Particles • Pocketed Vane Design Vane Designs GEN 1. AKA “CHEVRONS” - Now Used as Coalescer GEN 2. “HOOK TYPE”- Greater Liquid Retention GEN 3.- “HOOK 2”- Even Greater Liquid Retention- Higher P GEN. 4- “POCKET VANE” CURRENT ANDERSON DESIGN • Lowest P of 2,3,&4. • Highest Liquid Removal • Most Efficient Separation /FT^2 = SMALLER DIAMETER SEPARATORS Vane Performance • Standard Efficiency is 100% of 8 > Liquids only • Some Solids Entrained with Liquid OKConsult Factory • Addition of a Coalescing Mesh Pad Increases Efficiencies to 100% of 3 > • TURNDOWN IS EXCELLENT: Down to 10% of Design Flow in Every Case AVS Type In-Line Separators • Custom Designed Per Application • 100% of 8 Liquid • Limited Solids - Pockets Can Plug • Turndown ratio is 10 - 110% of Design Flow • Vanes are 316 L SS Construction Standard • Removable Vane Design Available • Increase to 100% of 3 With Mesh or Vane Coalesce • Ideal For All Gas Processes • No Slugging- 5% Maximum by Weight of Entrainment TOP VIEW AVGS Type Vertical Gas Separator • Same Principle as The AVS Type Separator • Primarily Used Where Liquid / Gas Ratios Exceed 5% by Weight • Also Used For Slugs Or Where Liquid Hold Up Is Desired To De-gas Liquids AVGS Type Vertical Gas Separator Double & Single Vane Bank Separators • Units Specifically Designed For Steam Drums • Same Technology As Previous Vane Separators • Single VS. Double Depends On Several Factors / Same Performance • Turndown 10-110 % of Operating Design Flow • Custom Built Per Application • 316L SS Vanes / CS Optional Anderson’s Centrifugal Type Separators • L and LC - Inline Separators Vertical Down Flow and Horizontal • TL - Inline Separators Horizontal Shorter face to face • 99% of 10 and Larger Liquid and Solid Particles Anderson’s Centrifugal Type Separators -Cont • Combination Separator Traps - 81S, HS, HSW - Inline • Exhaust Heads - Cast and Fabricated • BI - Internal Steam Drum Separator Anderson’s Centrifugal Type Separators - Cont. • AMCS - Multi-Cyclone Separator • Handles Heavy Solid Loadings • 100% of 8 and Larger Liquid Particles • 100% of 5 and Larger Solid Particles • 99% of 5 to 8 and Larger Liquid Particles L Type Centrifugal Separator • ASME Code Design Standard • 2-1/2 Inch to 12 Inch Flanged unit standard • Two Standard Models: -150 PSIG (10 BARG) @ 500 ºF (260 ºC) -300 PSIG (20 BARG) @ 500 ºF (260 ºC) • Horizontal & Vertical Down Flow (Vert. Down Flow Has Higher Liquid Capacities) • HI-EF Element Standard • Low Press Drop (<1 PSI, .01 BAR F-F) • Very Economical For ASME Code Unit • Popular w/ Air Compressors / Steam Systems / Refining • 99% of 10 : 2:1 TURNDOWN • Solids & Liquids • Maximum Entrainment: 5% By Weight LS Type Centrifugal Separator • “S” Stands For Special • Any Special Material 304, 316, and Exotics • Sizes Above 12” • Non Standard Pressures • Special Configurations • Mix & Match Elements • Popular w/ A&E Firms, OEMS • Same Efficiency: 99% 10 , 2:1 Typical Turndown. 5% by Weight Anderson’s Centrifugal Type Separators wet gas • HOW CENTRIFUGALS WORK • PERFORMANCE • QUICK SIZING Clean Gas AMCS Multi-Cyclone Centrifugal Separator • Nested Multi-Cyclone Elements. • Excellent For Dry Only, Low Maintenance • Efficiency: 100% of 5 Solids, 100% of 8 Liquids. • Versus HI-EF Centrifugal: More Efficient But Higher P (2-3 PSID OVERALL) • Basic Design No Slugging, MAX 5% Liquid/Solids by Weight • High Liquid Capacity Models Available AMCS Multi-Cyclone Centrifugal Separator AMCS Multi-Cyclone Centrifugal Separator Anderson’s Filter Type Separators • AFS - Filter Separator -Filters used in combination with one other method • 100% of 3 and Larger Liquid and Solid Particles • 99% of .5 to 3 Solid Particles Anderson’s Filter Type Separators - Cont. • ADG- Dry Gas Filter Separator -Filters Only • 100% of 3 and Solid Particles • 99% of .5 to 3 Solid Particles Anderson’s Filter Type Separators - Cont. • ACF - Coalesce Filter Separator -Filters and / or one other method • 99.98% of .3 Solid Particles and Aerosol Mist AFS Filter / Separator • Multiple Stages (Impingement-Filtration-CoalescingImpingement) No Slugging • High Efficiency- 100% Liquids & Solids 3 • 99% of Solids 0.5 to 3 • Horizontal or Vertical Designs • Different Separation Elements Available AFS Filter / Separator ACF Coalescing Filter Separator • Gas Polishing Coalescing Filter • Extra High Efficiency: 99.98% of 0.3 • Solids and Liquids • Filters are Expensive: Usually Want To Precede With Liquid / Solid Separator, OR: • Knockout Baffle in Lower Chamber , HI-EF, Vane, Or Multi-Cyclone to do Bulk Liquid Cleanup. - Extends Life Filters • Applications Include Gas Turbine Inlet, Oil Removal From Compressor Outlets ACF Coalescing Filter Separator ADG Dry Gas Filter • Solids Only (Dry Gas) - Can Coalesce Liquids, But Liquids Will Carry Through • Max Temp: 300°F STD, Up To 700 °F Special • 100% Of 3 , 99% OF .5 To 3 • P 1/2-1 PSID New & Clean, 8-10 PSID Change Out ADG Dry Gas Filter Required Information • The Big Picture • Gas • Flow Rate • Removal of What? • Slugging / High Solids • Required Removal Efficiency • Minimum / Maximum Operating Pressure • Minimum / Maximum Operating Temp. Required Information • Pressure Drop • Arrangement • Connections • Materials • ASME Code Information Instrumentation Gage Glass Liquid Level Controller Liquid Level Switches Dump Valves Pressure / Temp. Gauges Relief Valves P Indicators and Transmitters Conclusion • Separators are critical pieces of equipment for the smooth operation of most all processes. • Different applications require different approaches, different styles of separators, and sometimes units in combination. • IT IS IMPORTANT TO GET ALL THE INFORMATION CORRECT THE FIRST TIME-- SAVES TIME AND $$ More Than Just A Separator. . . Systems Design & Integration Filtration Services Equipment Design & Manufacturing ® ®