swirlseparators

advertisement

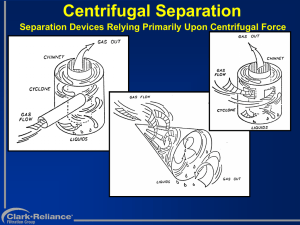

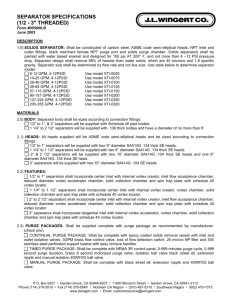

Facts and Fiction About Swirl Separators and Hydroclones Aquacultural literature will sometimes use the terms swirl separator and hydroclone interchangeably. However, although swirl separators and hydroclones function to remove solids from a fluid, the process in which this is done is distinctly different between the two. HYDROCLONES Rely primarily on centrifugal force and unique hydrodynamics to separate and remove solids. Inlet water enters the hydroclone tangentially at the top of the unit. At high water velocity, considerable g forces of up to 7,500 are created. This centrifugal action separates particles by pushing them to the boundary layer along the outside wall of the hydroclone. Picture taken from “Aquacultural Engineering”, Wheaton, 1985 As water spirals downward into the conical area, it becomes restricted. At the apex of the hydroclone some water leaves via the undeflow while the remaining water is forced back upward. This upward moving water forms a “free vortex” that spirals upward through the center of the hydroclone. Formation of the free vortex is critical to proper solids removal. Picture taken from “Hydroclones”, L. Svarovsky, 1984. Centrifugal force separates the solids, while the hydrodynamics created by the free vortex removes the separated solids. The main features that affect hydroclone performance are: Diameter- Larger the diameter, the larger the cut size. Inlet Diameter-Larger the diameter, larger the cut size. Conical Angle- Greater the angle, larger the cut size, especially beyond 25o Vortex Finder Diameter- Larger the diameter, larger the cut size. Note: Cut size refers to the particle size where 50% of particles at that size will be removed by the hydroclone. Clearly, it can be seen that hydroclone efficiency to remove small particles is reduced as hydroclones increase in size. Small hydroclones with high velocity rates are capable of removing particles <10 um in diameter. However, in commercial aquaculture operations, a properly designed hydroclone should remove approximately 80% of particles above 77 um. SWIRL SEPARATORS Unlike hydroclones, swirl separators remove particles through sedimentation NOT centrifugation. Therefore, a well designed swirl separator should consider particle settling velocity, volumetric flow rates and design features that enhance sedimentation. Unlike hydroclones, the higher the volumetric flow rate, the less efficient swirl separators become. Out Let Flow Settling Particle Velocity Inlet Flow Upward Water Velocity Important design features: Inlet design- Recent studies have shown that tangential inlets (as are commonly used) result in less efficient solids removal versus non-tangential inlets. Tangential inlets increase water velocity and create turbulence, both of which are counterproductive features in a swirl separator. Inlet designs that show the best removal efficiency consist of a downward spout situated in the centre with a deflection plate. Another efficient inlet design incorporates a rectangular shape. Central inlet with deflection plate Picture taken from “Solids Removal in Freshwater Recirculating Aquaculture Systems” Rectangular Inlet Picture taken from “Solids Removal in Freshwater Recirculating Aquaculture Systems” Regardless of what inlet structure is chosen, the key elements that should be considered for inlet design are: 1. Reduce turbulence. 2. Slow and disperse in-flow. 3. Minimize short circuiting. Outlet Design- Outlets that offer the best solids removal are weir type designs that encompass the entire periphery of the swirl separator. Whatever, outlet design is chosen, the main concern is to choose a design that slows the water velocity (by having a large volume capacity), creates quiescent conditions and promotes water flow over the entire volume (inhibits short circuiting). Modeling shows that a well designed swirl separator should be approximately 88% efficient at removing aquacultural solids and display a cut size of approximately 150 um. In field studies, however, have found swirl separators to be only 44-48% efficient. This poor performance may, however, be due to the fact that swirl separators have been designed with centrifugal separation in mind, when in fact the primary mode of removal is via sedimentation.