IGCC for Power generation – an environmentally benign and

advertisement

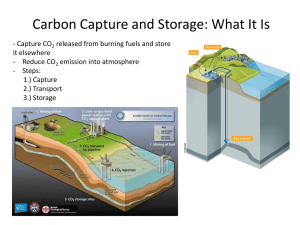

IGCC for Power generation & By Dr. D.N. Reddy, Director Er. K. Basu, Adviser Dr. V.K. Sethi, Research Adviser Centre for Energy Technology, University College of Engineering (Autonomous) Osmania University, Hyderabad – 500 007, India. – Total installed capacity over 1,00,000 MW – Thermal power generation has emerged as the principal source of electric power in India contributing to about 70% – Coal fired thermal stations are in predominance and share about 84% of the total thermal installed capacity. – It is prudent and economical to develop methods and process for efficient utilization of low-grade Indian coals for power generation. – Gasification of coal is the cleanest way of utilization of coal, while combined cycle power generation gives the highest efficiency. – Integration of these two technologies in IGCC power generation offers the benefits of very low emissions and efficiencies of the order of 44-48%. – The comparative indices show that in case of IGCC, emission of particulate, NOx and SOx are: 7.1%, 20% and 16%, respectively, of the corresponding emissions from PC plant. – Environmental performance of IGCC thus far exceeds that of conventional and even supercritical plants. – Three major areas of technology that will contribute to improvements in IGCC are : hot gas de-sulfurisation hot gas particulate removal advanced turbine systems – Commercialization of IGCC needs technology demonstration at an intermediate scale of about 100 MW to address the issues such as: hot gas clean ups and system optimization and to establish reliability and performance. – This would also enable to design an optimum module for air blown gasification, which in multiples would constitute a commercial size plant in the range of 300-600 MW. – The present study addresses these issues and suggests suitable technologies for Indian Coals. VISION 2020 PROGRAM In-combustion Clean-up Fluidized bed combustion (CFBC, PFBC, AFBC) Gasification using + fluidized bed, moving bed or Entrant bed Gasifiers Post combustion Clean-upDesulfurization (FGC systems) Supercritical Pre combustion Cleanup beneficiation/washing CLEAN COAL TECHNOLOGIES Technologies for utilization of Coal for Power Generation with minimal pollutants discharged to the atmosphere (Reduced CO2, Sox, Nox, SPM) at high conversion efficiency……….W.C.I. Schematic Layout of the Integrated Gasification Combined Cycle Steam Flue Gas to Stack BFW HRSG Steam Steam Turbine Steam Coal Compressed Air Hot Gas Gasifier Fuel gas Gas Cleanup Gas turbine Power Ash Sulfur Air Comparison of various Power Plants * Power Plant Concepts Major Components Efficiency % Cost per MW (Rs. Crore/MW PC fired Thermal Boiler, Steam turbine, Coal handling and other BOP 34-37 3.8-4.0 CC Plant Gas turbine, Steam turbine, Waste hear recovery boiler 40 3.2-3.4 IGCC (Coal) Coal preparation unit, gasifier, steam turbine, Gas cleaning GT, WHTSG 46* (estimated) 4.86-4.95** IGCC (Pet Coke) Air separation unit GT, ST, WHRSG, Gas Clean up 48* (with G/H class Gas turbines) 4.25-4.30** Super Critical As for PC fired Thermal plus spiral tubes and high temp alloys 37.5-39.5 3.95-4.10 High efficiency coupled with low emission (SPM: 7%, Sox:16%, Nox:21% of corresponding PC Plant) ** For Indigenous Units through systematic transfer of Technology Identified R&D Areas are: – Process process optimization of selected gasification – Improvement of design and reliability of plant components & Resource Optimization – Optimization of overall plant heat integration and layout – Hot gas cleanup COAL GASIFICATION – SELECTION OF GASIFICATION PROCESS The fluidised bed process has many technical and environmental advantages over the moving bed process, such as, – The fluidised bed can use any amount of fines whereas in the moving bed only 10% of fines can be used. – In the fluidized bed process, hydrocarbon, liquid byproducts such as tar, oil and gas-liquor are not produced and, hence, the pollution is reduced. – High ash coals can also be successfully gasified in the fluidised bed. BENEFITS EXPECTED FROM IGCC • India endowed with large coal reserves over 200 billion tonnes. • Environmental benefits due to higher efficiency of conversion and reduced SPM, SOx, NOx levels can be achieved using coal based IGCC technology. • Retrofit/Re-power options for gas based CCGT plants by installing only coal based gasifiers are cost effective (opportunity cost low) and are environmentally benign. • Adoption of IGCC technology in India has ‘Global’ as well as ‘National’ benefits. IGCC DEVELOPMENT PROGRAM IN INDIA • Pioneering work on IGCC development in India taken up by BHEL in early eighties. • Major Mile Stones – Choice of gasification for high ash coals by BHEL – 6.2 MW IGCC demonstration plant established by BHEL both with moving Bed and Fluidized bed. – Coal characterization by BHEL & IICT for gasification application. – Intensive data generated by IICT on oxygen-steam gasification in their moving bed gasifier. – Task force CEA, CSIR, NTPC & BHEL constituted to assess technological maturity & financial requirement for a green field IGCC plant of 100 MW capacity at Dadri (NTPC). – BHEL, CSIR & NTPC prepared proposal for setting up of this 100 MW IGCC demonstration plant. – Experience on the fluidized bed process is, very limited in the country. – Internationally, the experience gained so far is only for low ash coals. – Thus there is a need for taking up extensive R&D on IGCC Pilot Plant using high ash (4050% Ash) Indian Coals. Technology-related issues in IGCC – Design of Advanced gasifiers (optimum gas composition, optimum scale-up etc.) – Hot gas cleaning (de-sulphurisation and particulate removal) – Advanced gas turbines (blade design to sustain ash laden gas) – CO2 emission abatement in IGCC Power Plants – Operating conditions of IGCC plants in transient stage – Configuration of an optimized system for IGCC Fuel – related issues In a Raw Pet-Coke and refinery residue based IGCC Plant – System optimization, particularly the balance of plant – Optimized Heat balance diagrams – Scaling up of gasifiers to optimum size In a Coal/Lignite based IGCC Plant – – – – – Process & Plant conceptual design De-sulfurization of syngas of high sulfur coal and lignite Optimized Heat balance diagrams Super critical Vs IGCC in Indian context Application of ASME PTC-47 code for IGCC for high ash coals and lignite SOME IMPORTANT FINDINGS ……… • Reactive solid sorbent de-sulfurization combined with hot gas cleaning through ash and sorbent particle removal provides for higher energy efficiency to an extent of 4-7%. • The current Capital cost of building an IGCC power plant is of the order of Rupees 6 crore/ MW. • Improvements in hot gas cleaning coupled with Cycle optimization shall bring down the cost drastically to a level of $ 1000/kW or about Rupees 4.5 crore/MW The efficiency of refinery bottom based IGCC unit will be about 2% higher than that of coal based IGCC unit. Refinery based IGCC plants - Advantages Co-generation of steam Co-production of hydrogen gas & recovery of sulfur element No use of limestone, as required for CFBC technology No requirement of extra land for disposal of solid waste In the long run the refinery based IGCC technology is equally attractive to coal based IGCC from economic and environmental considerations. SOME FINDINGS RELATED TO COMMERCIALIZATION OF TECHNOLGOY At present it may be prudent to implement the project in phased manner to absorb the risk of gasifier in the total project wrap-up guarantees fig. 1 A Technology Transfer model for determination of velocity of Transfer of Technology (TOT) is an useful tool for TOT of a frontier technology from a developed economy to a developing economy fig. 2 Typical results of the velocity of TOT are : (With year 2000 as base) IGCC (oxygen blown) - Pet coke Normal pace Accelerated ------- 5 years 2 years (Fig 3) IGCC (Air Blown) Normal pace Accelerated ---------- Coal 7 years 5 years ( Fig 4) Fig. 1 16 Fig. 2 1 Fig. 3 36 Fig. 4 1 Super Critical PC Power Plant (15 oC Amb.) Net Thermal Efficiency (%) 60 Super Critical PC Power Plant (Indian Condition) IGCC (15 oC Amb) 55 IGCC (Indian Condition) 50 45 566 oC Sub Critical PC Power Plant (Indian Condition) 1500 oC 1300o C 623 oC 600o C 40 1184o C 650o C 35 Ceramic gas turbine 540oC 30 1990 1995 2000 2005 2010 Year of commercial use Fig.5 EFFICIENCY IMPROVEMENT FORECAST CONVENTIONAL Vs IGCC