Coal Gasification – A PRB Overview

advertisement

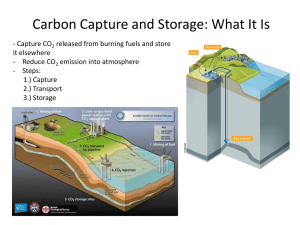

Coal Gasification : A PRB Overview Mark Davies – Kennecott Energy Outline • Background – Our Interest • History – Development of IGCC • Current status – Commercial Technology • Poly generation - Synthetic Fuels • Issues for PRB • The Future • Questions ??? Our Interest - Sustainable Development “development that meets the needs of the present generation without undermining the capacity of future generations to meet their needs.” Rio Tinto’s commitment to SD: Ensure our businesses,operations and products contribute to the global transition to sustainable development Coal’s Sustainability Challenge • Economic and social criteria make a compelling case for coal – the issue is environmental performance • Climate change concerns present a complex challenge for the continuing use of fossil fuels and coal in particular Integrated Gasification Combined Cycle (IGCC) IGCC is essentially ready for use by the coal industry, which has largely been spared the expense of its development Twenty years ago oil refinery practice in North America and Europe underwent a fundamental change as available crude became heavier This had two implications: • A significant increase in hydrogen demand to 'sweeten' the heavier crude; and • Increased production of highly contaminated petcoke and heavy refinery residues Simultaneously, aerospace technology was being applied to the utility sector to create natural gas fired turbines; and coal based IGCC started becoming a viable technology Implication – Current commercial technologies were developed for Petcoke Natural Gas Combined Cycle (NGCC) • • • • • • • Natural gas Gas turbine Heat recovery steam generator Steam turbine High efficiency Low capital • • Simple vs. PC plants Cookie-cutter design Low emissions Integrated Gasification Combined Cycle (IGCC) Gasification is essentially partial oxidation under pressure IGCC + Carbon Capture and Storage Current Commercial Technology Shell • • • • Lock hopper feed Water cooled Syngas cooler PRB capable at cost GE (Chevron Texaco) • • • • Slurry feed Refectory lined Quench available Not PRB capable ConocoPhillips (E-Gas) • • • • Slurry feed Refectory lined 2 Stage ??? Impact of Coal Type • Any coal or biomass feedstock can be gasified • The issue is the economics! • Gasification is most efficient with low moisture, low ash and high heating value feedstock's 1.40 IGCC Capital Cost (E-Gas) Relative Heat Rate or Capital Cost 1.35 IGCC Heat Rate (E-Gas) PC Capital Cost 1.30 PC Heat Rate 1.25 1.20 1.15 Illinois #6 1.10 Pittsburgh #8 1.05 TX Lignite 1.00 5,000 6,000 7,000 WY PRB 8,000 9,000 10,000 11,000 12,000 13,000 14,000 15,000 Coal Heating Value, Btu/lb HHV Source: EPRI Issues for PRB • Capital cost disadvantage may be mitigated by fuel cost • Petcoke/PRB blends can be attractive • New technology • DOE/Southern Transport Reactor • Alternate slurry technology • Commercial vendors have little ongoing development Indicative Cost of Electricity Coal PRB Coal Illinois coal 0 5 10 15 20 25 30 35 40 Cost ($/MWhr) Capital Cost ($/MWh) Other Fixed Costs ($/MWh) Fuel Expense ($/MWh) Variable O&M ($/MWh) Polygeneration Syngas is a prime petrochemical feedstock Traditionally produced by reforming natural gas “Natural gas” from Syngas • Methane reformer • CO + 2H2 + Catalyst => CH4 + clean up Liquid chemicals from Syngas • Clean diesels • Methanol Indicative breakeven – current technology • Liquid Fuels $30 - $35 bbl • Synthetic natural gas - $5.50 - $7 /MBTU* * Source – DOE IGCC + CCS + Poly generation Barriers to IGCC Commercial Deployment • Cost → 10-20% penalty for bituminous coal • Traditional PC can meet current environmental standards • IGCC financing costs higher than PC – perceived risk • • • profile No reward for risk taking – new plants largely being built by regulated utilities Excess capacity in many regions - NGCC overbuild IGCC needs more project development than NGCC or PC • To date no standard IGCC design - this will change with GE entry • Lack of familiarity with IGCC in the power industry (it is a chemical plant) Future Issues • Environmental regulation, community pressure, uncertainty • • • • • – particularly carbon Sustained Federal research effort to resolve cost, reliability concerns • Especially on low-rank coals Critical to establish viability and acceptability of carbon capture and storage • e.g. FutureGen Development of of integrated, optimized designs • GE/Bechtel • ConocoPhillips/Fluor Deployment incentives to overcome commercial penalty (e.g. incentives, production tax credits, etc) Costs should come down as new plants are built and improved designs become standard