B9 Coal

B9 Coal

Deploying Fuel Cells to Generate Cheap,

Clean Electricity from Fossil Fuels

The next step in the CCS revolution …

B9 Coal present the next step in the CCS clean energy revolution employing a unique Integrated Gasification Fuel Cell (IGFC) process

Addressing both the rising cost of energy and the need to reduce global

CO

2 emissions it combines the gasification of coal with the use of hydrogen to generate electricity with fuel cells

Key advantages of IGFC power plants

• Efficiency

• Cost of the CCS

• Captures upwards of 90% CO

2

• Lower cost

• Flexible output

• High reliability

• Lower environmental footprint

• Scaleable

…transforming coal from the dirtiest fossil fuel to the cleanest

B9 Coal

A revolution in clean energy generation

Surface Coal

Gasification

(SCG)

AFC Energy’s

Alkaline Fuel

Cell System

Underground

Coal

Gasification

(UCG)

Gas

Separation

Carbon Transport and Storage

Gasification

Coal can be reacted at high temperatures with a controlled amount of oxygen to produce synthesis gas (syngas)

Underground Coal Gasification (UCG)

Gasifying coal in situ carries additional commercial and environmental advantages

Gas Separation

Syngas is cleaned of impurities and split into near pure streams of hydrogen and carbon dioxide

AFC Energy’s Alkaline Fuel Cell

The most efficient way of producing electricity from hydrogen

Large Scale Energy Generation

Using the hydrogen from syngas AFC Energy’s fuel cell system is the cheapest, cleanest and most flexible way to produce electricity from fossil fuels

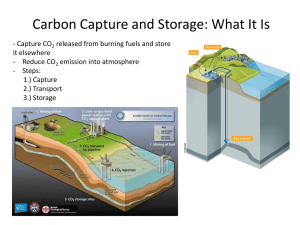

Carbon Transport and Storage

Captured carbon dioxide is compressed, transported and stored in geological structures to prevent its escape into the atmosphere

Compression

• Compressed to reduce volume

•

Compressed to dense phase >90bar

Ship Transport

• Trucks or ships are suitable for transportation of small volumes or over long distances

•

CO

2 is liquefied for ship transport

•

Shipping of liquefied CO

2 similar to shipping liquefied petroleum gases (LPG)

Pipeline Transport

• Compressed CO

2 is transported in a dense, liquid like phase

• Better economically and environmentally than shipping

•

Large-scale transportation of CO

2 in pipelines has taken place for over 30 years in the US

•

Case Study:

Snøhvit project, North Sea

Came on stream in 2007, transports 700,000 tonnes CO

2 natural gas facility to the Snøhvit oil and gas field per year for 145km from a liquid Saline Aquifers

•

Aquifers are sandstone formations that hold saline water

•

CO is pumped into the sandstone, filling the pore spaces

2

• Largest capacity storage options

• Case Study: The Sleipner Project, North Sea

250km off coast of Norway, around 1 million tonnes CO

2 removed from the Sleipner West Gas Field per annum and injected into aquifer 800m below seabed Saline Aquifer

Depleted Gas/Oil Field

Depleted gas fields

Sandstone formations that held natural gas

The shale cap which once prevented the gas from escaping now holds in the CO

2

Potential field location and geology already well known

Reduced costs - number of existing pipelines and rigs could be used

Confidence - millions of tonnes of gas and oil already stored securely

UK well suited - close to North Sea gas fields

B9 Coal

A revolution in clean energy generation

Surface Coal

Gasification

(SCG)

AFC Energy’s

Alkaline Fuel

Cell System

Underground

Coal

Gasification

(UCG)

Gas

Separation

Carbon Transport and Storage

B9 Coal present…

Clean

Potential for upwards of 90% carbon capture

Green Small footprint power plants: no turbines or other heavy infrastructure; AFC Energy’s fuel cells are made from lightweight recyclable materials and cartridges are refurbishable

Efficient

Alkaline fuel cells are the most efficient way of converting hydrogen to electricity; carbon capture as part of the process with no loss of efficiency

Low cost Minimal infrastructure means low capital costs; AFC Energy’s fuel cells are cheap to manufacture; low running costs as fuel cell maintenance is simple

Small footprint

No turbines, minimal infrastructure

Fully scalable

Modular nature of the fuel cells means capacity can be increased to meet demand

Load following

Modular fuel cell system allows output to be increased or decreased with no loss in efficiency

Reliable

Alkaline Fuel Cells are 99.999% reliable as they are a solid state technology

…a game-changing clean energy proposition

B9 Projects in action…

Project plan

• Powerfuel is constructing a large scale IGCC power station with carbon capture capability at Hatfield site

• Initial construction will involve 800 MW combined cycle gas turbine (CCGT) facility optimised for 'syngas' conversion and operation

• Powerfuel to convert CCGT plant into 900 MW IGCC power station fuelled by extensive coal resources at Hatfield colliery

• The syngas can be used to produce hydrogen as a feedstock for 330 MW of alkaline fuel cells power generation

…300MW installation alongside IGCC plant

B9 Coal…

B9 Coal

’s low cost, flexible, clean energy proposition will

revolutionise

the way we produce

electricity

, providing an essential step in the move to a

low carbon

future and acting as a global template for clean

energy generation

.

…the future of clean energy