HACCP TRAINING

advertisement

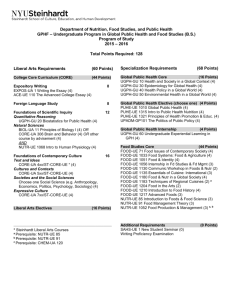

HACCP TRAINING Reference: NCDPI http://www.ncpublicschools.org/childnutrition/publica tions/foodsafety/ HACCP BINDER 2 Consists of the following: • FOOD SAFETY TEAM • SCHOOL DESCRIPTION • OPERATION ASSESSMENT • PREREQUISITE PROGRAMS • SAFE FOOD HANDLING PROCEDURES • MONITORING AND RECORD KEEPING • CORRECTIVE ACTIONS • VERIFICATION • TRAINING • CRISIS MANAGEMENT • DONATING FOODS • RECALLS AND TRACEBACK FOOD SAFETY TEAM • • • • • • • • • • • THE LEADER IS THE CAFETERIA MANAGER. THE MANAGER WILL BE RESPONSIBLE FOR FOLLOWING: MONITOR PREREQUISITE PROGRAM STANDARDS. MONITOR SAFE FOOD HANDLING PRACTICES. MAINTAIN APPROPRIATE RECORDS. TRAIN FOODSERVICE EMPLOYEES. THE MANAGER IN A SMALL CAFETERIA MAY HAVE TO BE RESPONSIBLE FOR ALL THESE. PROGRAMS THAT MAY BE ASSIGNED TO ASSIST ARE: MONITORING PREREQUISITE PROGRAMS Safe Food Handling Procedures Operation Assessment Prerequisite Programs Safe Food Handling Practices • • START OPERATION ASSESSMENT BY COLLECTING LAST SY Health Inspections for the last 3 yrs and chronologically file behind pg. 1; newest on top and as year progresses you remove copy of oldest report. Keep previous 3 yrs records of HACCP Records. • • Thoroughly read and review Prerequisite Programs, and Safe Food Handling Practices. Prerequisite Programs contains the Food Safety Checklist for new employees and Subs; It is highly recommended that you use this also for yearly refresher training for your staff. Complete training log after you hold the training. Safe Food Handling Practices • Section contains: • Practices that are based on the 2009 FDA Food Code. • Covers practices from Purchasing to the serving and holding of foods. • Tables on transportation vehicle criteria; Shelf life of foods, minimum cooking temperatures; use of the Winston CVAP cabinet; List of Potentially Hazardous foods; calibrating thermometers and how to use thermometer; safe methods of cooling foods. Monitoring and Record Keeping • • This tracks how well managers and the food safety Team are implementing the HACCP plan. Helps you determine if your employees know the standards in the Prerequisite Programs and if Safe Food handling practices are being met. • • • • NEW The Daily cooling log for PHF’s. NCDPI recognizes that you are not present 4 to 6 hrs after the end of the meal period; So the following recommended procedure should be followed: Record date, observers initials, product name, start time & temperature. Just before observer leaves record time and temperature once more. Manager initials validating proper procedures were practiced to ensure safe temperature is reached. Monitoring and Record Keeping continued. • • • • The daily temperature and monitoring logs are to be checked 5 of the 7 day week. If Holiday, week-end or school out, then one line out in remaining cells. Recommend these forms be completed before food preparation is started. The Hot holding unit does not include the steam table, employees monitor the temperature of the food before it is placed on steam line and enter that temperature on production record. Target temp. is 135 (f). • • The Daily Hand sink Assessment is to be completed for all hand sinks in kitchen as well as boys and girls restroom nearest to cafeteria. Water temp. must be at least 100 (f), measure once or twice. Simply feel warm water, if compliant mark with a “y”. All sinks must have antimicrobial soap, and single use towels or air dryer. Monitoring and Record Keeping Continued • • • • • • Daily Operation Assessment, entries if correct, mark by an “X”. Daily check sanitizer concentrations. Milk Box assessment, temperature of milk box must be 39 (f) or colder, check use by date on milk also. Refrigerator assessment consists of temperature, and check for improperly stored food items that can cross contaminate. For walk in coolers, food stored at least 6” off floor. Leftovers—record the temperature of any leftover, even if you intend on discarding the item. This provides anyone a clear picture of the way the foods were handled during the entire meal service. Leftovers may not be frozen or used beyond three days • • • IN BACK OF THIS SECTION IS THE PRODUCTION RECORD. Block 1: enter only menu items that are PH. Temperature recording is for the 1st pan only. Record the safe cooking/holding temperature of PH foods. Record the target end cooking temperature or target uncooked foods temperature. Record the actual food temperature when removed from cold/hot holding unit and before it is placed on serving line. Record the Total Planned Student Meals Reimbursable meals only in col. (9a) prior to ordering food. Help in forecasting is found in col. (13, 14, 15). Col. (9b) consists of the Total planned meals (ala carte & adult meals). Remember, the milk and condiment entries cannot exceed the planned student meals. Reasonable entries also for vegetable choices or fruit since only two choices can be made, i.e. 300 Green beans, your col. (9b) would not exceed 600 servings. Corrective actions Verification Training • The corrective actions section is to be known and accessible to CN Employees so that they will know what appropriate corrective action is to be taken. • Verification is defined as the process of evaluating the HACCP plan to determine that standards are being properly implemented, monitored, and observations recorded. • Training and orientation of Subs and New employees is required. The Manager must completed a Food Safety Checklist found in the prerequisite section. • It is permissible and advisable to use the Food safety Checklist as an annual training with returning employees. HACCP COMPLETE • Allergens: All Staff members will know where the confidential list of Students Special Diet. • All staff will know how to read food labels and review menu. • Staff will know the Big 8 allergens. • Thank you for your attention today! • This completes the training on HACCP principals. • This module will be available on our website. Please use it for your staff, one or two staff members can self manage this module and will be able to complete in app. 10 minutes.