Food Safety Courses for Food Manufacturers (1)

advertisement

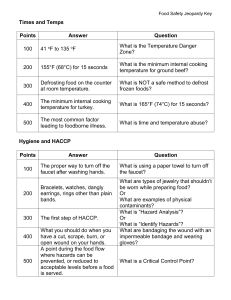

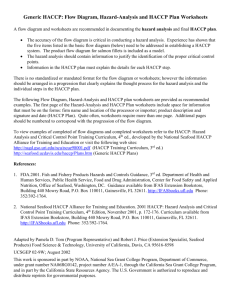

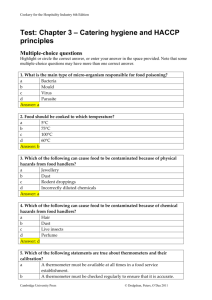

Food Safety Courses for Food Manufacturers April 2014 - Missoula, Montana Host: Mission Mountain Food Enterprise Center Better Process Control School – April 7-8 Time: 8:00 am–5:00 pm – Lunch on your own Instructors: Dr. Richard Dougherty, Dr. Karen Killinger Cost: $150 Hazard Analysis Critical Control Points (HACCP) – April 9-10 Time: 8:00 am–5:00 pm – Lunch on your own Instructors: Dr. Richard Dougherty, Dr. Karen Killinger Cost: $150 See course information on page 2 Location: MSU Extension Conference Room 2825 Santa Fe Court, Missoula, Mt. 59808 Directions: www.missoulaeduplace.org To register for one or both courses please log in at: https://lccdc.ecenterdirect.com/Conferences.action and sign up. For more information about the workshops contact Mission Mountain’s Facility Food Safety Coordinator, Yvette Rodriguez at 406-6760676 x 106 or by email: Yvette.Rodriguez@lakecountycdc.org. Please send payment to: Lake County Community Development Corp., 407 Main St. S.W. Ronan, Mt. 59864. Please identify which training(s) you are taking. About the instructors: Dr. Richard Dougherty, Extension Food Science Specialist in the School of Food Science, Washington State University. Dr. Dougherty joined WSU in 1990 after spending more than 15 years in the food processing and packaging industries. He conducts workshops and conferences on food safety, regulatory issues, low acid and acidified foods processing, HACCP, SQF, product development, and food business development. His experience has included management of quality assurance, product development, regulatory affairs, research, and technical services for food processing and related operations. Dr. Karen Killinger joined WSU in 2006 as an Assistant Professor and Consumer Food Safety Specialist. Dr. Killinger is a coinstructor in HACCP and also leads the Good Agricultural Practices Workshops team. Sponsored by: Course Information Better Process Control School Regulations for thermally processed low acid and acidified foods packaged in hermetically sealed containers (21 CFR 108, 113, and 114) are designed to prevent public health problems from commercially canned foods. The regulations require that operators of processing and packaging systems and container closure inspectors be under the operating supervision of a person who has attended and successfully completed appropriate instruction prescribed by FDA. Regulations for thermally processed meat and poultry products (9 CFR 318.300 and 381.300) and thermally processed low acid animal foods (21 CFR 507 and 508) include similar training requirements. Better Process Control Schools (BPCS) provide practical applications of principles set forth in the regulations and satisfy the training requirements of both FDA and USDA. Washington State University is approved by the FDA to offer these schools which satisfy the FDA, USDA, and State education requirements for canned low acid and acidified foods. WSU offers a two-day course for processors of acidified foods in glass containers as well as the four-day schools which covers all process systems and all types of containers and closures. Private instruction tailored specifically to individual company needs is also available. The two-day course includes the following subjects: • Applicable Regulations • Microbiology of Thermally Processed Foods • Acidified Foods • Food Container Handling • Food Plant Sanitation • Records for Product Protection • Principles of Thermal Processing • Instrumentation and Equipment • Closures for Glass Containers HACCP – Hazard Analysis Critical Control Point HACCP is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution, and consumption of finished product. HACCP is not a zero risk system, but is designed to minimize the risk of food safety. HACCP is being successfully applied to all segments of the food industry from growing, harvesting, processing, manufacturing, distributing, and merchandising to preparing food for consumption. Prerequisite programs such as Good Manufacturing Practices (GMP’s) are an essential foundation for the development and implementation of successful HACCP plans. The five preliminary steps and seven principles of HACCP have been universally accepted by government agencies, trade associations, and the food industry around the world. These steps, covered in the two-day training, are: Five preliminary steps o Assemble the HACCP Team o Describe the food and its distribution o Describe the intended use and consumers of the food o Develop a flow diagram that describes the process o Verify the flow diagram Seven principles of HACCP o Conduct a hazard analysis o Determine critical control points o Establish critical limits o Establish monitoring procedures o Establish corrective actions o Establish verification procedures o Establish record keeping and documentation procedures For successful implementation of a HACCP plan, management must be strongly committed to the HACCP concept. A firm commitment to HACCP by top management provides company employees with a sense of the importance of producing safe food. Washington State University’s Food Processing team offers practical Basic HACCP training that satisfies each of the education requirements of mandatory HACCP regulations. Further, our Basic HACCP training is applicable to any food-related system. Our instructors have been formally trained to deliver HACCP for Seafood, Meat & Poultry, and Juice systems. The three-day program is recognized as an acceptable prerequisite to SQF Systems training as well.