haccp assignment

advertisement

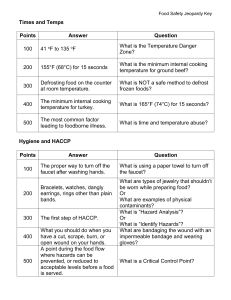

Meredith Murphy The Hazard Analysis and Critical Control Points (HACCP) system is a mandatory procedure followed in the food service business. There are seven steps of HACCP that are designed to identify and prevent the spread of bacteria or other health and safety hazards in food production. Principle 1: Conduct a hazard analysis. Morrison Food Service at The University of Texas Medical Branch is under the Compass Group Americas Division. Morrison follows specific food production protocol to determine potentially hazardous foods, work areas, sanitation procedures, etc. A food safety hazard is any biological, chemical, or physical property that may cause a food to be unsafe for human consumption. The guidance document to ensure each of the preventative measures and prerequisite systems are in place to support an effective HACCP approach are provided to all food operations under the Compass group’s Quality Assurance department. The HACCP approach is utilized all the way from when the foods or other supplies are purchased to when they are served. Multiple prerequisite procedures are used throughout the critical control checkpoints during production. While visiting the production kitchen I noticed many places where the plant had used posters and reminder signs on how to safely handle, clean, produce, and cook foods. The HACCP plan provided to Morrison food service facilities refers to these ‘reminders’ as prerequisites. For example, by each hand washing station were step-by-step directions to safely and properly wash ones hands, fingers, and nails. I noted many posters and signs that listed detailed instructions for other prerequisites such as, washing fruits and vegetables thoroughly, and the proper sanitation of china, silver ware, and hot plates etc. Another example of proof the facility had conducted a hazard analysis, was a cutting board chart indicating a color code to avoid cross-contamination between cutting boards, knives, and food. Right beside the chart that was a sanitation guideline for both plastic and cut-resistant glove use. In the food service tray building area located inside John Sealy, I noticed the requirement of sanitation buckets at tray-line, mandatory single-glove use, and hairnets on all employees working on the line. Principle 2: Identify critical control points. The critical control points (CCPs) for Morrison have been identified. These CCPs are classified as a step or procedure, in a food process where specific controls can be utilized. By identifying CCPs, many potentially hazardous food production outcomes are prevented, eliminated, completely reduced, or lowered to acceptable levels. The following critical control points utilized at Morrison include purchasing, receiving, storage, thawing, cooking, hot and cold holding, cooling, reheating, and transport. Each of the critical control points used at Morrison have ‘standards’ developed that describe the required supplier, acceptable food temperatures at both the receiving and cold storage CCPSs. Other standards included for various CCPs in appropriate thawing procedures, minimum cooking temperatures, holding/ cooling temperatures for hot and cold foods, reheating temperatures, and transport of foods. Meredith Murphy During receiving specific tasks include inspecting items for damage, insect infestation, or mishandling. Food must also be stored promptly upon receiving, and precautions should be followed, for example; raw foods should always be stored below cooked foods, foods must also be stored within certain areas away from the floor and below the ceiling, and the (FIFO) method must be used to rotate stock. While touring the production kitchen I saw where the foods were received, stored, prepared, and also where utensils were cleaned. On the tour, the executive Chef Jeff pointed out the area for FIFO items. This method ensures that employees eliminate waste, or unnecessary spoilage. All employees are trained to look for items they needed in that area first, before opening new ones. Any time a common ingredient is not found it the FIFO area, an employee can replace the ingredient in FIFO area once they have used what they need from it. It is important that all fresh produce and stored open ingredients always have a orange label on them identifying when they were opened their shelf life. Principle 3: Establish critical limits for each critical control point. A critical limit is the maximum or minimum value to which a food safety hazard must be controlled at a CCP to prevent, eliminate, or reduce the reference issue to an acceptable level. Food safety hazards could involve (i.e. physical, biological, or chemical) deviations from an acceptable standard. Examples of critical limit for CCP’s Receiving: Cold foods are received at 41°F/5°C or below. Frozen foods are received frozen solid. Storage: Refrigerators are maintained at 40°F/4.4°C or below Cooking: Proper internal cooking temperatures; Roast Beef, Fish (145°F), Eggs, Pork, Ground Beef (155°F), Hamburger (158°F), Poultry, Turkey (165°F) In the production unit, the area where foods were received was located very close to both dry and cold storage. I noticed a HACCP compliance plan poster with the critical limits for receiving foods. There were specific instructions for the standards, monitoring, corrective action, and record keeping on the poster as well. Principle 4: Establish critical control point monitoring requirements. Monitoring activities are necessary to ensure that the process is under control at each critical control point. Food Safety Inspection Services (FSIS) require that each monitoring procedure and its frequency (i.e. how many times a day) be listed in the HACCP plan. When necessary, “monitoring notes” are included under each CCP, and appropriate “logging forms” are posted and then maintained in binders. Meredith Murphy Examples of Monitoring for CCP’s Storage: Temperatures of storage rooms are checked at least 2 times daily. Cooking: Product temperatures are checked before the cooking process has ended. Hot & Cold Holding: Potentially hazardous food temperatures are checked (and recorded) at least once every 1-2 hours at all stations where food is held hot or cold pending service or use (i.e. gravy at a steam table). In addition, temperatures of all potentially hazardous foods removed from warmers, refrigerators, or production areas to replenish hot and cold holding stations are checked (not necessary to record). In the production facility, I did notice another poster related to the cooling CCP. Specifically, the monitoring task for cooling procedures was to review temperatures on either the 4-hour temperature record log, or cooler temperature Audit Procedure log. The monitoring task for receiving food was to check about 5-10% of incoming refrigerated potentially hazardous foods (i.e. 5-10 out of 100 items) with an approved thermometer. In the tray-line area, I noticed monitoring forms for hot food holding on the refrigerators. Principle 5: Establish corrective actions. Corrective actions must be developed in the condition that a monitoring requirement deviates from an established critical limit. Corrective actions serve to ensure that no product harmful to health as a result of the deviation enters sales or distribution. When necessary, Morrison does include “corrective actions” for CCP’s. Example of Corrective action for CCP’s Receiving: Cold food is rejected if the temperature is above 50°F/10°C; temperatures of 46°F/7.8°C require management intervention. Frozen foods that have started to thaw are rejected, unless the food will be thawed, and cooked within 24 hours. Storage: Potentially hazardous foods that have been at temperatures above 40°F/4.4°C for more than 2 hours are discarded; otherwise goods are relocated to a properly functioning unit. Cooling: If the food has not reached 70°F/21°C within 2 hours, or 40°F/4.4°C within an additional 4 hours, the food is reheated; then cooled using an appropriate method. Otherwise the food is discarded. (Only one reheating is permitted.) I noticed corrective actions for receiving foods, cooling foods, and cold holding around the facility. However, I did not notice a poster for each of the other CCPs around the facility. Meredith Murphy Principle 6: Establish record keeping procedures. It is required by HACCP regulation for food service facilities to maintain and keep records of certain documents, such as its written HACCP plan. In addition, records documenting the monitoring of critical control points, critical limits, verification activities, and the handling of processing deviations. When necessary, Morrison does have record-keeping forms to fill out that vary based on the critical control point. I noticed where the executive chef kept binders full of these kinds of records on file. I also noticed the current refrigerator logs posted by the refrigerators around the facility. Example of record keeping Receiving: Food Delivery Record (Form QAF-2) or equivalent record is maintained Storage: Cold Storage Temperature Log (Form QAF-4) or other equivalent record is maintained Hot and Cold Holding: Food holding Temperature Log (Form QAF-3) or equivalent record is maintained Principle 7: Establish procedures for verifying the HACCP system is working as intended. Validation ensures that the plans do what they were designed to do, meaning they are confident the kitchen has produced safe products. Verification ensures the HACCP plan is adequate and working as intended. Examples of verification procedures involve review of HACCP plans, CCP records, critical limits and microbial sampling. Just this past week I was present the day of Health Inspection, and during that certain microbial testing and analysis was done. Luckily, the production kitchen passed their Health Inspection. When discussing how the facility handles Principle 7 of HACCP this with the executive chef, he mentioned how many of his staff has daily responsibilities and tasks they are randomly evaluated on. Some employees work specifically work with the foods being received, where some work specifically with handling vegetable cleaning, and then others are solely responsible for sanitation and dishes. Every so often there are in-service trainings, and meetings to ensure that all the staff are aware of issues going on, and also able to work on fixing problems around different areas of the production process. These are ways that the HACCP system designed for UTMB is validated and working as intended. Meredith Murphy The Hospital Food Service system at UTMB is different than the majority of hospital food service facilities in other parts of the country. This is due to the fact that Hurricane Ike hit Galveston Island in 2008 and flooded the entire first floor of The John Sealy Hospital. Federal Insurance Mitigation Administration is a natural disaster insurance company that covers damage costs at UTMB for hurricanes and other natural disaster occurrences. FIMA agreed to cover the costs of a temporary production kitchen across Harborside while the new Rebecca Sealy Hospital is under construction. All food is currently produced at the temporary production trailer, and then transported via-van to the tray line room to be plated, and taken to patient rooms. FIMA required that in the new hospital the kitchen be located on the 6th floor of the building in the event another hurricane hit, the damage would not be nearly as large as it had been when the kitchen was on the 1st floor. Once the 6th floor kitchen is ready in the new hospital, both patient services and the production kitchen will share one large area again and become more united team. I felt that the modification on a common recipe served to John Sealy patients should be made done to the production of the fresh steamed vegetables including broccoli, green beans, carrots, etc. commonly served as side items. Currently all these veggie sides are prepared in the temporary production kitchen across the street, and then brought over to tray-line using multiple CCPs and HACCP guidelines. Because these are very basic, and simple production items, I felt they could realistically be prepared from raw in the tray-line room. The basic modification necessary would be to have all raw veggies that would be prepared as sides via a steaming technique be delivered to location of the old kitchen, where patient service is still located (tray-line area). One employee could be responsible for cleaning, prepping, and steaming the veggies in the same area they were going to be plated for service. This would reduce the burden of responsibilities at the production trailer kitchen and allow for less transport of hot foods. My rationale for this modification to ensure food safety is basically to allow for fresher foods that aren’t exposed to prolonged unnecessary heat. The vegetables could be prepared in the patient services area so they are cooked fresh to order using a mobile or temporary steamer oven placed in patient services. This would allow for a lower burden placed on those responsible for checking the temperature of these items when they were received, and the items would just be served richer in their nutrients. We know that more nutrients are lost with prolonged heating, and causes an unattractive appearance of these sensitive vegetables drastically decreases resulting in a wilted look, and unpleasant texture. An interesting point the executive chef mentioned was that if an employee could handle the procedures for food service at UTMB, they could work anywhere. By making the modification of where side items such as those that can be prepared via steaming or poaching techniques, some of the hot and cold food holding procedures for transportation under HACCP could be eliminated.