RFID

advertisement

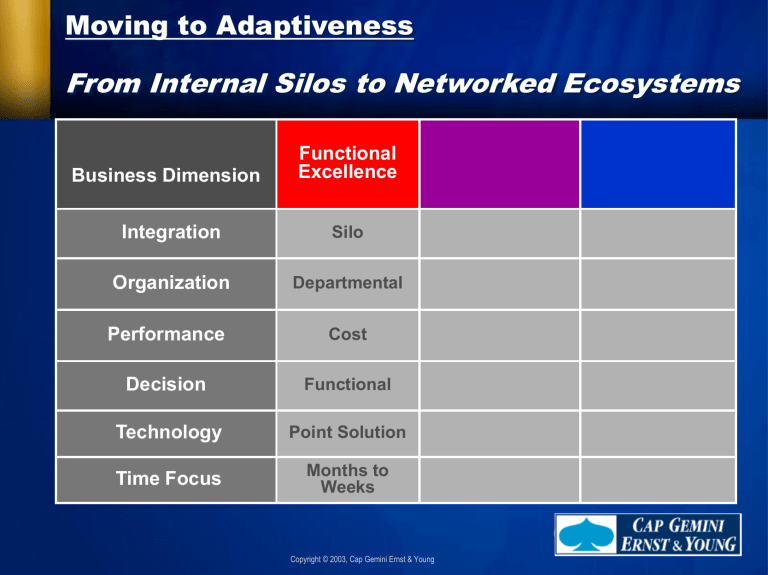

Moving to Adaptiveness From Internal Silos to Networked Ecosystems Business Dimension Functional Excellence Integration Silo Organization Departmental Performance Cost Decision Functional Technology Point Solution Time Focus Months to Weeks Copyright © 2003, Cap Gemini Ernst & Young Moving to Adaptiveness From Internal Silos to Networked Ecosystems Functional Excellence Integrated Supply Chain Integration Silo Enterprise Organization Departmental Centralized Performance Cost Cost & Service Decision Functional Process Focused Technology Point Solution ERP / Bolt-on Time Focus Months to Weeks Weeks to Days Business Dimension Copyright © 2003, Cap Gemini Ernst & Young Moving to Adaptiveness From Internal Silos to Networked Ecosystems Functional Excellence Integrated Supply Chain Adaptive Supply Chains Integration Silo Enterprise Extended Enterprise Organization Departmental Centralized Collaborative Performance Cost Cost & Service Profit & Productivity Decision Functional Process-Focused Event-Based, Agent-Assisted Technology Point Solution ERP/Bolt-On Interdependent, Web-Connected Time Focus Months to Weeks Weeks to Days Real-Time EXECUTION MINDSET Business Dimension Copyright © 2003, Cap Gemini Ernst & Young Moving to Adaptiveness Some Enabling Processes / Technologies RFID (Radio Frequency Identification) Supply Chain Outsourcing (BPO) Consumer-Based Replenishment Service Parts Logistics Product Lifecycle Management Supply Chain Event Management Performance Metrics in SCM Supplier Relationships Copyright © 2003, Cap Gemini Ernst & Young RFID RFID Technology Allows Goods to Be Identified and Monitored Via a Wireless Tag Device: a tag / label with identification that is read electronically Minimal issues with orientation and obscurity compared to barcodes Tags can be electronic chips Have storage capabilities and power sources that provide versatility System: device + reader/writer + controller Device – tag / label Reader/writer – to communicate with device Controller – manages data interface with computer systems In short, RFID is like a bar code that can talk Sources: ABI, VDC, Philips, IDTechEx, HP Docs Copyright © 2003, Cap Gemini Ernst & Young RFID RFID: A $15B to $25B Market by 2015 Applications Tracking, Tracing, Inventory Management Anti-Counterfeiting Safety, Security Numerous others Market players Alien Technology Checkpoint Matrics Intermec As with all new technologies, there are issues, barriers, and adoption challenges Common standard Tag cost System integration Privacy Readability Copyright © 2003, Cap Gemini Ernst & Young RFID Experts Predict Cost per Tag Will Be as Low as 5¢ Within 18 Months (in 2001: $30 per tag) Gillette ordered 500 million tags this year P&G thinks RFID can cut its inventory levels almost in half Wal-Mart have put its suppliers on notice, using RFID will become a requirement to remain a supplier No other technology in the last 20 years has had as much potential to impact the economy’s trillion-dollar inventory levels as RFID! Copyright © 2003, Cap Gemini Ernst & Young RFID There are Numerous Applications of RFID Across the Supply Chain Item Level Inventory Tracking Product Lifecycle Management Automatic Receiving Security Inventory Reduction Shrinkage Intelligent Shelf In Store Inventory Automatic Checkout Last 50 yards Product Related On Sell Raw Material Improved Production Planning Manufacturer Asset Tracking Finished Goods / Warehouse Manufacturer Plant Maintenance Proof of Delivery Distribution Fleet Maintenance & Repairs Retailer Vendor Managed Inventory Waste Disposal In Store Reactive Marketing In Store Availability Characteristics of Adaptive Supply Chain Execution Real Time Visible Proactive Event Driven Intelligent Responsive Collaborative Coordinated Closed-Loop The solution now exists with no shortage of problems to solve. The key is to drive functionality beyond “a super-barcode” Copyright © 2003, Cap Gemini Ernst & Young