RFID & IT for Supply Chain Management

advertisement

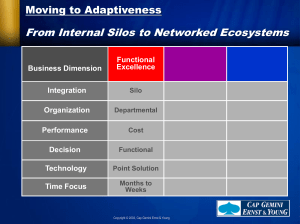

Supply Chain Management Managing the between all of the parties directly and indirectly involved in the procurement of a product or raw material. Players in a Supply Chain 1. Materials flow from suppliers and their “upstream” suppliers at all levels down to you 2. Transformation of materials into semi-finished and finished products through the organization’s own production process 3. Distribution of products to customers and their “downstream” customers at all levels 4. A , from the order being made until its delivery to the customer Basic Supply Chain Management Components • Plan for that go toward meeting customer demand for products and services. • S • T products • Logistics: the • Plan for the to deliver goods and services needed. into semi-finished and finished ITs role in supply chain • Visibility and the • Modeling, simulation and various forecasting tools to combine information from various sources to figure out what is needed (or might be needed) when. • E faster at a lower cost – Communication and successful supply chain allows everyone to react for a • Key Element: quickly flowing from one entity or stage to another one (both upstream and downstream) Focus of Organizational Supply Chain Strategies • Efficiency: focus on – Getting the (optimize resources) – Looks at throughput, speed, availability • Throughput: the volume that can be sent through the system • Effectiveness: focus on – Setting the right goals and objectives and making sure they get accomplished. • Looks at through increases • Do , conversion rates, sell- and/or Do – How much of each do you do? – Sometimes, you have to trade one for the other. SUPPLY CHAIN DRIVERS • Organizations use these four drivers to support either a supply chain strategy focusing on efficiency or a supply chain strategy focusing on effectiveness Facilities • Efficiency (saves money at expense of other things) – Economies of scale when facilities centralized. Saves money but further from customers and longer to deliver – Save money by building a facility that is only big enough to handle production requirements – A single product focus lets me do a really good job producing just one thing. • Effectiveness (tends to increase costs) – Goods can get to customers faster with more facilities – Building in lots of extra capacity provides flexibility – A multi-product focus may allow me to perform the same operation on many different things. Inventory • Efficiency (saves money at expense of other things) – Saves money by not holding much inventory or using as much space. Incoming shipments must be received more frequently. – A company can save money by not maintaining as much safety stock, but runs the risk of disappointing customers if inventory runs out during a busy season (such as Christmas) – Single storage location • Effectiveness (tends to increase costs) – Spend money to hold larger amounts of inventory so as to immediately be able to respond to customer needs. – A company spends money by maintaining higher amounts of safety stock so as to not run out during busy times (Christmas), but not enough demand may lead to price cuts and losses. – Multiple storage locations (close to customers) • Decide whether to risk the expense of carrying too much inventory (effective) or run the risk of losing sales (efficient) Transportation • Primary transportation methods – Truck, rail, ship, air, pipeline, electronic • Speed of delivery and price of delivery are difference drivers • Efficiency (saves money at expense of other things) – A company can save money by shipping goods inexpensively, but this takes longer for the customer to receive the goods. – Inexpensive shipping = Efficiency • Effectiveness (tends to increase costs) – To ensure speedy delivery, a more expensive delivery method is selected. – More expensive shipping = Effective – A company that uses Federal Express to ship goods is focusing on safe and timely delivery and not on the cost of delivery. • Regardless of which transportation method is selected, having a global inventory management system is vital (ability to track and locate all components and materials in both the upstream and downstream portions of the supply chain) Information • An organization must decide how and what information it wants to share with its supply chain partners • Efficiency (saves money at expense of other things) – Freely sharing lots of information increases the speed and decreases the cost of supply chain processing. – Pull strategy: partners are responsible for retrieving/pulling information when they need/want it (and they bear the cost of getting info) – Must trust partners when letting them access your systems. Partners control when info is pulled • Effectiveness (tends to increase costs) – Share only selected information with certain individuals, which will decrease the speed and increase the costs of supply chain processing – Push strategy: you send info to partners when YOU want to (partners may have to wait to get what they need and you bear the cost of sending/pushing info to them – Using a push strategy, your organization controls what is shared and when it is shared. Wal-Mart’s strong information flows allow it to operate its business in a just-in-time fashion (JIT inventory) Global Inventory Management Systems • Let you locate and track items moving through your supply chain. – Lets you know Radio Frequency Identification (RFID) Uses a in a tag or label to back and forth between an object and a receiving device. http://www.youtube.com/watch?v=oAvQcYcvyaw http://www.youtube.com/watch?v=eob532iEpqk http://www.youtube.com/watch?v=4Zj7txoDxbE Radio Frequency Identification (RFID) – Can be used to inventory, inventory and product . – Pay at toll road plazas. – Purchase products without standing in line (just walk past a scanner with the product). – Pr – Manufacturing –B tracking and – KSU uses RFID in the parking garage to track customers and customer types ( customers, to areas, , including length of stay) – US passports now have RFID chips containing information about the passport holder. RFID RFID Architecture Information Technology and Supply Chain Management • Advances in information technology have made it possible to bring to life the idea of a truly integrated the supply chain. – The key is to have as close to throughout the entire supply chain as possible. • I can see and you can see – Real-time flow of accurate information with minimal time lags (communication is key) • An organization needs to select its SC strategy and then IT can be used to implement and enhance that strategy. • RFID is one of the technologies used in supply chain management.