(JSA) Guideline

advertisement

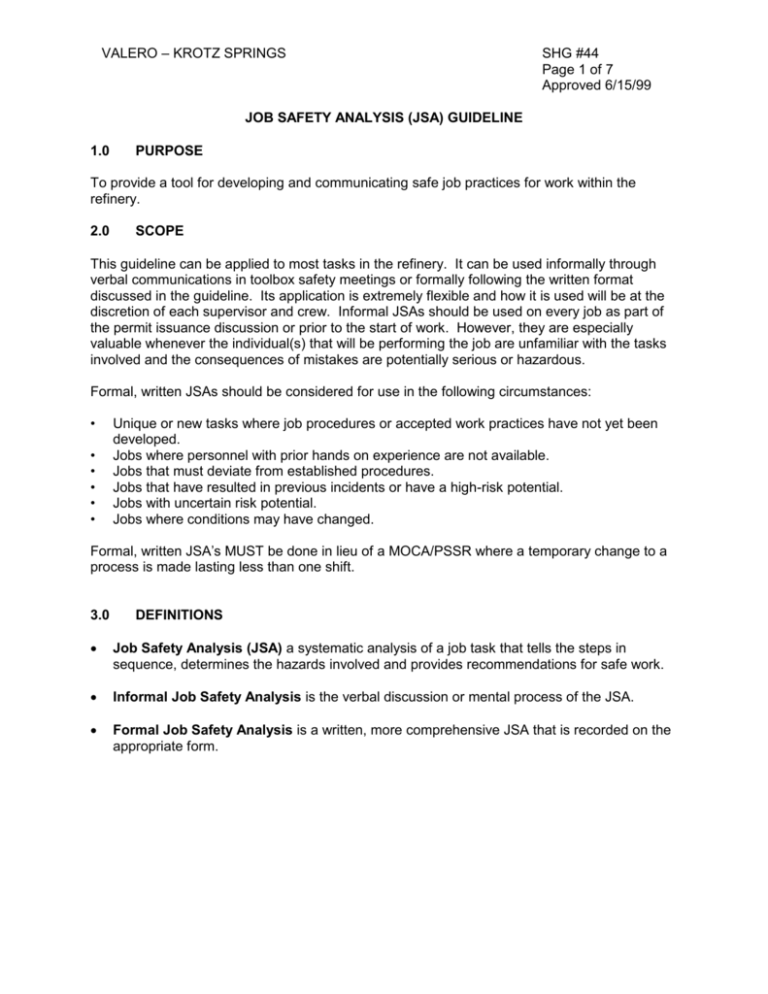

VALERO – KROTZ SPRINGS SHG #44 Page 1 of 7 Approved 6/15/99 JOB SAFETY ANALYSIS (JSA) GUIDELINE 1.0 PURPOSE To provide a tool for developing and communicating safe job practices for work within the refinery. 2.0 SCOPE This guideline can be applied to most tasks in the refinery. It can be used informally through verbal communications in toolbox safety meetings or formally following the written format discussed in the guideline. Its application is extremely flexible and how it is used will be at the discretion of each supervisor and crew. Informal JSAs should be used on every job as part of the permit issuance discussion or prior to the start of work. However, they are especially valuable whenever the individual(s) that will be performing the job are unfamiliar with the tasks involved and the consequences of mistakes are potentially serious or hazardous. Formal, written JSAs should be considered for use in the following circumstances: • • • • • • Unique or new tasks where job procedures or accepted work practices have not yet been developed. Jobs where personnel with prior hands on experience are not available. Jobs that must deviate from established procedures. Jobs that have resulted in previous incidents or have a high-risk potential. Jobs with uncertain risk potential. Jobs where conditions may have changed. Formal, written JSA’s MUST be done in lieu of a MOCA/PSSR where a temporary change to a process is made lasting less than one shift. 3.0 DEFINITIONS Job Safety Analysis (JSA) a systematic analysis of a job task that tells the steps in sequence, determines the hazards involved and provides recommendations for safe work. Informal Job Safety Analysis is the verbal discussion or mental process of the JSA. Formal Job Safety Analysis is a written, more comprehensive JSA that is recorded on the appropriate form. VALERO – KROTZ SPRINGS 4.0 SHG #44 Page 2 of 7 Approved 6/15/99 RESPONSIBILITY Individual/Group Directors/Managers Owning Area Supervisor Supervisors / Lead Techs Employees/Contractor Personnel Training Department Assigned Responsibilities Encourage and promote the use of JSAs Assure that training is provided for their personnel Encourage and promote the use of JSAs Assure that training is provided for their personnel Assure that formal, written JSAs are done when required and filed Coordinate formal JSAs and assist with informal JSAs as needed Act as Team Leader Assure that formal JSAs are reviewed with everyone involved in the job Review JSA at job completion for accuracy and completeness and correct as necessary. Use JSA in daily tasks Recognize and request formal JSAs Communicate information obtained during informal JSAs with everyone involved in the job Arrange training for all employees and appropriate refinery contractor personnel. 5.0 GUIDELINE There are eight steps in reviewing a job using the Job Safety Analysis technique. The steps are essentially the same whether the guideline is informal or formal. The amount of time to complete a JSA may be several seconds to several hours based on the complexity of the job. The eight steps are as follows: 5.1 Step 1 - Defining the Scope of the Job to be Analyzed Defining the scope of the analysis involves determining where the job to be reviewed starts and where it ends. A JSA can be very broad and cover pre- and post-job tasks like: selecting tools, spotting equipment, lockout/tagout, checking MSDSs, determining process variables (temperature, pressure, composition, etc), and cleaning up. Or it can be very specific and focus only on the part of the total job that is of concern or isn’t covered by other procedures and work practices. The scope will be defined by the individual, Lead Tech, and crew involved. VALERO – KROTZ SPRINGS SHG #44 Page 3 of 7 Approved 6/15/99 5.2 Step 2 - Determine If An Informal or Formal JSA Is More Appropriate For The Task This determination is based on the complexity of the task, the risk potential of the job, the experience level of the work group, and the amount of uncertainty involved. An informal or formal JSA can be conducted for most tasks. Informal JSAs may take the form of a crew toolbox safety meeting with the Supervisor or Lead Technician acting as Team Leader. It may also be two employees discussing what they are about to do at the job site. An informal JSA might be as simple as a single employee going through the process mentally before starting a task. A formal JSA should be performed for the types of jobs listed in the scope section of this guideline. It will provide a written procedure that can be used as a template for future jobs of similar nature. 5.3 Step 3 - Finding a Place To Meet , Assembling The People Involved, and Appointing a Team Leader/Scribe Performing a formal JSA requires assembling everyone involved in the job (where practical), as well as, anyone who has input into how to perform the job safely. The typical formal JSA meeting is held in a suitable meeting area with the Team Leader being the Supervisor/Lead Technician responsible for the work. A scribe will be necessary and should be appointed by the team leader. The scribe should complete the header portion of the JSA form and use the main portion to record the meeting as it progresses. Although not all inclusive, a typical team should consist of: Core JSA Team • • • • • Craft personnel involved Contractor craft personnel involved Owning Area Representative from where the work is taking place Valero Contractor Representative and contractor Foreman Supervisor/Lead Tech responsible for the job Optional Support Personnel – (to be contacted by the Team Leader) • • • Safety Department Representative Inspection, Tech Services Representative, etc. Environmental Department Representative VALERO – KROTZ SPRINGS SHG #44 Page 4 of 7 Approved 6/15/99 5.4 Step 4 - Breaking The Job Down Chronologically By Tasks Breaking the job down into a chronological listing of tasks is what makes the JSA process useful as a step-by-step work procedure. Existing procedures (Operating, Maintenance, etc.) should be reviewed in conjuction with the JSA. If this can be done in advance, the JSA study will proceed more smoothly. The job steps can be discussed verbally, reasoned through mentally or written out in the left-hand column of the JSA form (attached). Start with the first task of the job as identified in Step 1, and continue going through the tasks chronologically until the job is completed. Whether developing an informal or formal JSA, having a person experienced in doing the job present at the meeting is important. 5.5 Step 5 - Identifying the Hazards Involved With Each Task Identifying the hazards involved in each task is one of the main purposes for conducting a JSA. The hazards can be discussed verbally, reasoned through mentally or can be written in the center column of the JSA form. The checklist located on the backside of the JSA Form can be used to help identify the hazards associated with the job. Getting the right people involved in the meeting should ensure diverse points of view on what the hazards might be. Discuss or list all the credible hazards pointed out by the group, even those posed by associated work. 5.6 Step 6 - Developing Safeguards to Eliminate or Control the Hazards Identified This step involves controlling the hazards so the job will be performed safely. The safeguards can be discussed verbally, reasoned through mentally or written in the right hand column of the JSA form. The process of controlling hazards should be carried out in this order: • Eliminate or remove the hazard from the work area. • Guard against the hazard by physical barriers or distance. • Assign appropriate PPE. If none of these options will eliminate or control the hazard so that the task can be performed safely, that specific task should not be performed. At this point the JSA Team Leader and group should assess other options to performing the job safely without doing that particular task. 5.7 Step 7 - Review What Was Just Discussed Or Written With All Personnel Involved All personnel involved in the job who were not able to attend the meeting need to review and understand the JSA. The Supervisor/Lead Technician responsible for the work will review the JSA with all personnel involved. VALERO – KROTZ SPRINGS SHG #44 Page 5 of 7 Approved 6/15/99 5.8 Step 8 – After the job is completed, review the JSA for completeness and accuracy Note any steps which may have been omitted or were in the incorrect order. Note any hazards which weren’t anticipated and any safeguards which didn’t work as well as intended. If a formal JSA was prepared, revise the document per the observations noted. 6.0 Recordkeeping Copies of formal JSAs should be filed in the owning area Right To Know Station. SHG #44 Page 6 of 7 Approved 6/15/99 JOB SAFETY ANALYSIS FORM JOB: DATE: SAP FUNCTIONAL LOCATION/EQUIP. NO. DESCRIPTION OF JOB: JSA TEAM: PERSONAL PROTECTIVE EQUIPMENT REQUIRED: Steps in Sequence Hazards Involved Recommendations for Safe Work SHG #44 Page 7 of 7 Approved 6/15/99 THE PROACTIVE APPROACH TO INJURY PREVENTION Consider the following and check the items that apply to the job and then review with the work crew. Permits Required Cold Work Hot Work Vehicle Entry Excavation Confined Space Entry Posted At Job Site Signed Off When Complete Other Personal Protective Equipment Normal PPE • Hard Hat • Safety glasses • Work Gloves H2S Monitor Fire Retardant Clothing Rubber Gloves Leather Gloves Addt’l Foot Protection Respirators Rubber Boots Face Shield Mono Goggles Hearing Protection (Ear Plugs) Fall Protection Seat Belts Burning Goggles Welding Shield Other Tools Current Inspection Proper Tools For The Job Good Tool Condition Qualification Required Other Welding Welding Leads In Good Condition Combustibles Spark Containment Welding Screens (Personnel Protection) Grounding (near weld site) Water Hose Fire Extinguisher Fire Blanket Fire Watch ____ Cable Tray Cover Sewer Covers Other Electrical Locked & Tagged Try Start/Stop Switch CIFCI Test Assured Grounding Extension Cord Inspection Other Lifting Forklift Cherry Picker Load Chart Angle Crane Chainfall Proper Rigging Practices Manual Lifting Condition Of Equipment Critical Lift Other Hazards (Chemicals) Chemical Burns-Skin/Eyes Flammable Ingestion Inhalation Skin Contamination Other Hazards (Body) Fall Potential Pinch Points Slip-Trip Potential Thermal Burns Other Hazards (Environmental) Airborne, Particulates Electrical Shock Heat Stress Heavy Objects Hot, Cold Surfaces/Materials Inadequate Lighting First Opening Of Equipment Blinds Installed Valves Blocked Line or Equipment Cleared Noise Poor Access/Egress Poor Housekeeping Sharp Objects Other Access Scaffold (Properly Inspected Additional Comments; **Make sure employees have read and understand the requirements. Ladder (Tied Off) Aerial Lift Personnel Basket (Inspected & Approved) Special Provision Other Emergency Info/Equipment Location Fire Monitors Fire Extinguishers Safety Shower Evacuation Route Wind Direction Noted SCBA H2S FlammableGas Alarm Other