Alan Chorney – Troubleshooting_Costing

advertisement

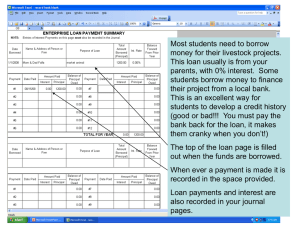

Troubleshooting Costing Alan Chorney Professional Services Visual South, Inc. Visualize Success 2012 Auditing Inventory Costs • • • • Cost Flow Inheritance Exception Auditing Inventory/Work In Process Reconciliation Audit Tools – Costing Tools – Reports – Correction Utilities Cost Flow - Inheritance ADJ Adjustments FG Receipts WIP Issues 3. Issue >>> 5. FG Receipts >>> Inventory >>>11. Transfers <<< PUR Receipts SLS Shipments Purchase Receipts •Purchase Receipts get their value from settings chosen in Application Global Maintenance –Standard Costing – Part Maintenance –Actual Costing - Source of Raw Materials •Purchase Order •A/P Voucher •Purchase Returns get their value from: –Receipt value of the FIFO Layers for the Part that was Received –Vouching Purchase Returns for a different value will create a Purchase Return Expense W.I.P. Issues •Inv. Trans. Issues take their value from the next available FIFO Layer •Linked PO Purchase Receipts are AutoIssued to WIP and inherit Purchase Costing •Issue Returns get their value from the issue layer for the Part that was Issued to WIP FG Receipts •FG Receipts take –Standard Costing •Part Standard –Actual Costing •Projected Value •Actual Value •FG Receipt Returns reinstate WIP Costs based on the prorated value of the original receipt Shipments •Shipments take their value from the next available FIFO Layer •Linked Work Orders Shipments are AutoReceived to FG and inherit WIP Costing •Shipment Returns get their value from the Weighted Average of the FIFO Layers for the Part that was Shipped on the Customer Order. •Linked Ship Returns Reinstate W.I.P. Adjustments •Adjust Ins take their value from •Adjust Outs take their value from the next available FIFO Layer •Part Maintenance •Inventory Transaction Value Override during data entry Adjust Outs do not reverse Adjust Ins Inventory Chart of Accounts Guidelines for Exception Auditing • Exception Auditing must be Designed into the chart of accounts • Total Inventory comprises only and all inventory control accounts • Product Codes supply the Sub-ordinate detail to the Total Inventory • Transaction Lines support the Product Code Summaries • All Interface Accounts, Product Codes and Overrides are VISUAL Control Accounts Exception Auditing Report Sub-Totals and Subordinate Parent Accounts synchronize to expose supporting Detail to the Transaction Level Work In Process Balance Report By Product Code Report Totals and Summary Parent Accounts synchronize to create a One-Look Bottom-Line Reconciliation Proper Period End Closing Summary (Manufacturing Activity) • 1. All Data entry for the period is complete • 2. Run Costing until no updates are found and Prepare Manufacturing Journals for the Period • 3. Post Manufacturing Journals for the Period • 4. Run Costing Tools for exceptions • 5. Correct any exceptions not due to future periods • 6. Repeat 3, 4, & 5 until exceptions are clear Auditing Inventory Costs (Inventory Reconciliation) •Print the Inventory Balance Report and compare to Account Balance •Verify all MFG Journals are Posted •Verify all Inventory Account Batches are PUR, WIP, FG, SLS or ADJ - Correct all other batch type balances •Correct PUR, FG, or ADJ Credits and WIP or SLS Debits •Correct PUR Debits that are from expense purchases •Print the final Inventory Balance Report and compare to Account Balance Print the Inventory Balance Report and Compare to Account Balance. GL=130,179.23 Inv.Bal=153,366.23 Verify all MFG Journals are Posted • Test for Unposted Transactions Verify all Inventory Account Batches are PUR, WIP, FG, SLS or ADJ • Use the Accounting Window to Inspect Accounts • Watch for Self Reversing Transactions Sub-Ledger detail maintains Transactional Logic Print the General Journal by Batch Type Correct PUR, FG, or ADJ Credits and WIP or SLS Debits. • Note the Credit Adjustment Self-Reversing Transactions Correct PUR Debits That are From Expense Purchases • Expect to see Debits from PUR, so watch for the Inventory Control Accounts being used on a line Think in terms of Transactional Logic - No Part_ID means No Inventory Transaction WIP - Work In Process • Four Work In Process (WIP) reports provide corroboration for G/L Balances – Ledger/Post MFG Journals/Reports/WIP Balance Report – Eng/Mfg/Work In Process Report – Eng/Mfg/Work Order Master Cost Report Comparative with Breakdown – Manufacturing Window Info Costs WIP – WIP Balance Report WIP – Work In Process Report WIP Report Corroboration Correct Exceptions Using Audit Tools • Check Exceptions using Costing Tools - Set Posting Candidate and Prep Journals • Check Cost Distribution Analysis – Recalculate Distributions/Force FIFO • Compare Inventory Reports for Qty & Value – VMFixWRK - Resummarize Work Order – VMFixOHQ - Fix Part table to Match Inv. Trans Table – VMFixIPB - Create Transactions to Match Part Location Table Costing Tools • Consists of three major areas of functionality: – Costing Tools – Analytical Reports – Recalculation Functions Costing Tools • Costing Tools is an enhanced version of the Print Preparation Analysis Report – – – – – Only Posting Candidates of “N” will come across as exceptions Ability to set individual Posting candidates Preparation of Journals Detail tables added WIP Balance check added • The design of the window is to identify possible costing exceptions. The exceptions do not directly point out G/L items. Each exception would need to be investigated to determine what correction, if any, needs to be performed. Costing Tools Types of Costs to check include: Purchases WIP Finished Goods Shipments Adjustments Indirect Labor WIP Balances Costs can be checked by ID or leave blank to check all items in the category. The posting date refers to the Total Posted column. This will show what has been posted up to that posting date. Filtering Options allow items to be viewed by Total Transactions and Total Transaction Detail. Exception Processing allows items to be viewed that show a difference between the Total Transaction amount and the Total Posted amount. Costing Tools Total Transactions and Total Posted amounts are Compared to determine If items need to be Re-evaluated. Note: A journal can be prepared without running Costing Utilities. Recalculation Functions • The Recalculation functions in Costing Tools include the following: – Recalculate Distributions – Recalculate Distributions W/Force FIFO – Recalculate WIP and Inventory Balances – Recalculate Standards (used as part of the process to reset standard part costs) Recalculate Distributions • Used to re-evaluate manufacturing activity distributions to the general ledger – Uses existing in transactions to update out transactions – Does not break linked transactions – Generally used when inventory transactions have been back dated Recalculate Distributions \ADMIN\COSTING TOOLS \ FILE \ RECALCULATE DISTRIBUTIONS Distributions can be recalculated for a range of parts or for all parts by leaving the range blank. Distributions can also be recalculated for non-part transactions. By indicating a date to Process transactions on or after, Recalculate Distributions will only process transactions after that date. Recalculate Distributions Recalculation Methods are based on the following three procedures: NOTE: All of the above procedures can create Distributions to the General Ledger. Recalculate Distributions COSTED POSTING TRANSACTION_ID PART_ID WORKORDER_BASE_ID TYPE CLASS QTY QTY CANDIDATE MATERIAL LABOR BURDEN SERVICE ============== ============================== ============================== ==== ===== ============== ============== ================= ================= =============== =============== ================ 11 MMC-FM0001 I A 3 3N 166.05 91.71 180 92.25 12 MMC-FM0001 I A 10 2N 553.5 305.72 600.02 307.5 13 MMC-FM0001 I A 4 0N 221.4 122.28 240 123 104 MMC-FM0001 O I 5 5N 276.75 152.85 300 153.75 124 MMC-FM0001 O I 5 5N 150 195.5 211.38 0 Recalculate Distributions COSTED POSTING TRANSACTION_ID PART_ID WORKORDER_BASE_ID TYPE CLASS QTY QTY CANDIDATE MATERIAL LABOR BURDEN SERVICE ============== ============================== ============================== ==== ===== ============== ============== ================= ================= =============== =============== ================ 11 MMC-FM0001 I A 3 3N 166.05 91.71 180 92.25 12 MMC-FM0001 I A 10 7N 553.5 305.72 600.02 307.5 13 MMC-FM0001 I A 4 0N 221.4 122.28 240 123 104 MMC-FM0001 O I 5 5N 276.75 152.85 300 153.75 124 MMC-FM0001 O I 5 5N 276.75 152.86 300.01 153.75 IN_TRANS_ID OUT_TRANS DIST_QTY MATERIAL LABOR BURDEN SERVICE =========== ====================== =========== =========== =========== =========== =========== =========== =========== =========== =========== 12 124 5 276.75 152.86 300.01 153.75 Recalculate Distributions – With Force FIFO Re-evaluation • Should only be run on a part-by-part basis • Breaks all links and re-builds them assigning costs based on transaction date – Out transactions may be re-valued based on backdated transactions Recalculate Balances – WIP & Inventory • Designed to re-populate Balance tables • Should be run after performing Recalculate Distributions to update the Balance table • Can be used for a range of parts or for all parts • Can be restricted to a specific posting date Recalculate Balances – WIP & Inventory Reports – Inventory Analysis • Inventory Valuation Reports – Inventory Balance – Inventory Valuation – Inventory Transactions • Costing Tools Reports (Used for reconciling inventory costs) – Cost Distribution – FIFO Distribution Inventory Valuation Reports The Four Inventory Reports: • Ledger/Post MFG Journals / File - Inventory Balance Report – Uses the Persistent Transaction Detail Tables to Balance to the General Ledger • Reports/Inventory Valuation Report – Posted Value Traces back through the Distribution Tables for In and Out Values – Cost Layer Detail shows Inventory Transaction Valuation by Costed Quantity vs. Quantity • Tools/Inventory Transaction Entry/Print... – Shows the Transaction Value of each Inventory movement as it is right now Cost Distribution Analysis Compares Transaction against Posted Values This report shows the Demand/Supply relationship. Out layer cost (Shipment - out of inventory) with the IN layers that are “Costed” against the Out transaction. Any difference between the Out Amt. and the In Amt. indicates a cost layer corruption that will require the Distributions to be recalculated. Costing Tools : FIFO Analysis Reveals Source & Use instead of Demand & Supply IN layer cost (Cost layers in inventory) with the OUT layer information Corrective Utilities • The following utilities are available to correct exceptions in addition to the Recalculate functions: – VMFIXWRK – Re-summarizes work order information – VMFIXIPB – Corrects imported part balances – VMFIXOHQ - Re-sets on-hand quantity information Thank You • alan.chorney@visualsouth.com