Contractor Safety Management - Fauji Fertilizer Bin Qasim Ltd.

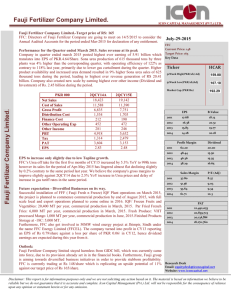

advertisement

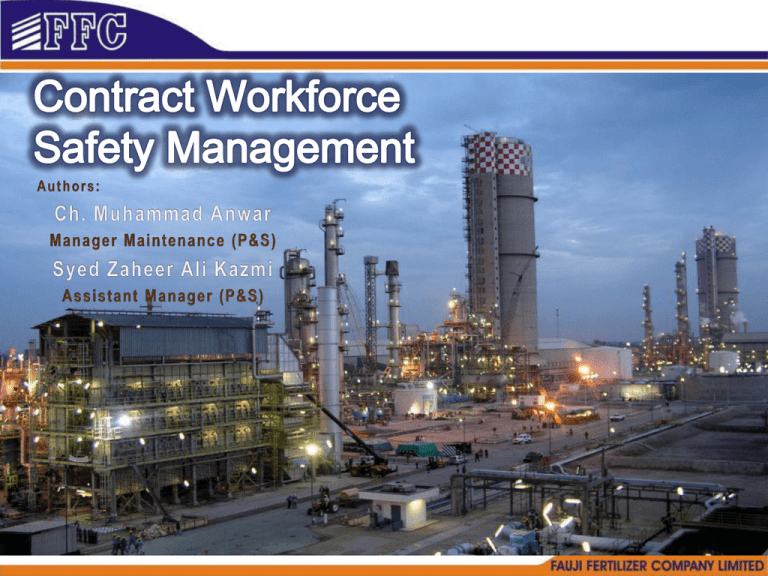

Fauji Fertilizer Company Limited Fauji Fertilizer Company Limited Introduction • The largest Urea Fertilizer Manufacturing & Marketing Company in Pakistan • Ranked at 8th position in the International Benchmark survey of fertilizer industry worldwide. • Amongst the top 25 Stock Exchange companies • Operating 03 world scale Ammonia-Urea plants • Major stakeholder of FFC Bin Qasim Limited • One of the leading companies in Pakistan for implementing the Safety Management System at workplace Contract Workforce Safety Management Contents 1. Contract Workforce Composition 2. Safety Concerns 3. Incident Prevention Program 4. Contractor Performance & Evaluation 1- Contract Workforce Composition Trades Skilled Workforce 40% Un-Skilled Workforce 60% 2- Safety Concerns Total FFC Incidents (2008-9) Contract Workforce Incidents Contract 70% FFC 30% By Controlling the Un-safe Conditions & Acts, the number of injuries can be reduced 2- Safety Concerns Common Factors Leading to Incidents 2.1- Behavior Loose Dress Un-safe Habits Ignorance 2.2 - Attitude Mind-set Resistance to change Low stakes 2.3 - Work Style Short term approach Risk taker Shuffling of trade 2.4 - Health Communicable disease Malnutrition Phobia 2.5 - Morality & Addiction 3 - Incident Prevention Program 3.1 - Awareness & Training Safety Induction before the job Pre-qualification of skilled workforce Monday is the Safety Talk Day Tool-box safety talk before start of the job 3 - Incident Prevention Program 3.2 - Discipline at the workplace Shipshape dungaree, overalls or pant & shirt Use of necessary PPEs Closed shoes at the workplace Smoking at smoke cabins only Driving Safety Permit for drivers Adherence to Traffic Safety Rules Housekeeping 3 - Incident Prevention Program 3.3 - Making Tools & Tackles Safe All PPEs and Tools are provided by FFC The special tools / equipment of contractors are tested / verified by FFC. Inspection of the contractor’s tool boxes / PPEs Undertaking by the contractor that all the PPEs used by his workforce are fit and maintained all the time. Tools clearance after job completion 3 - Incident Prevention Program 3.4 - Executing The Job Safely Job Supervision by FFC employee Compliance to procedures Job Safety analysis Checklists for specific jobs Safety Audits Monitoring & Controlling of Job Shuffling Dress code for Specialized works 4 . Contractor Performance Safety Pre-qualification Contractor’s responsibilities and legal aspects System based feedback from the end-user Data base of complaints / feedback Contractor performance evaluation 4.1 - End-user Feed back Form 4.2- Contractor Performance Evaluation Belief & Discipline - Together Work Organization - Doing it for Safety Job Supervision – Strengthens Safety Safety and Production, Hand-in-Hand Safety Performance SAFETY PERFORMANCE CONTRACTOR MANPOWER 3.5 3.33 3 MAN HOURS 2.5 2.19 2 1.86 1.5 1 0.5 0 07 08 09 10 11 12 YEAR Contractor Manpower – Man-hour of safe operation logging started in 2007 – Highest ever 3.3 Million Man-hours of Safe Operation Achieved 13 Unrivalled Excellence Safety Induction Literature Pre-qualified Skilled Worker Entry Sheet of Safety qualified Worker More than 1800 casual manpower individuals have been Safety Certified since July 2008 Safety Talks Status